Revision 1 – 04.12.2015 21/28

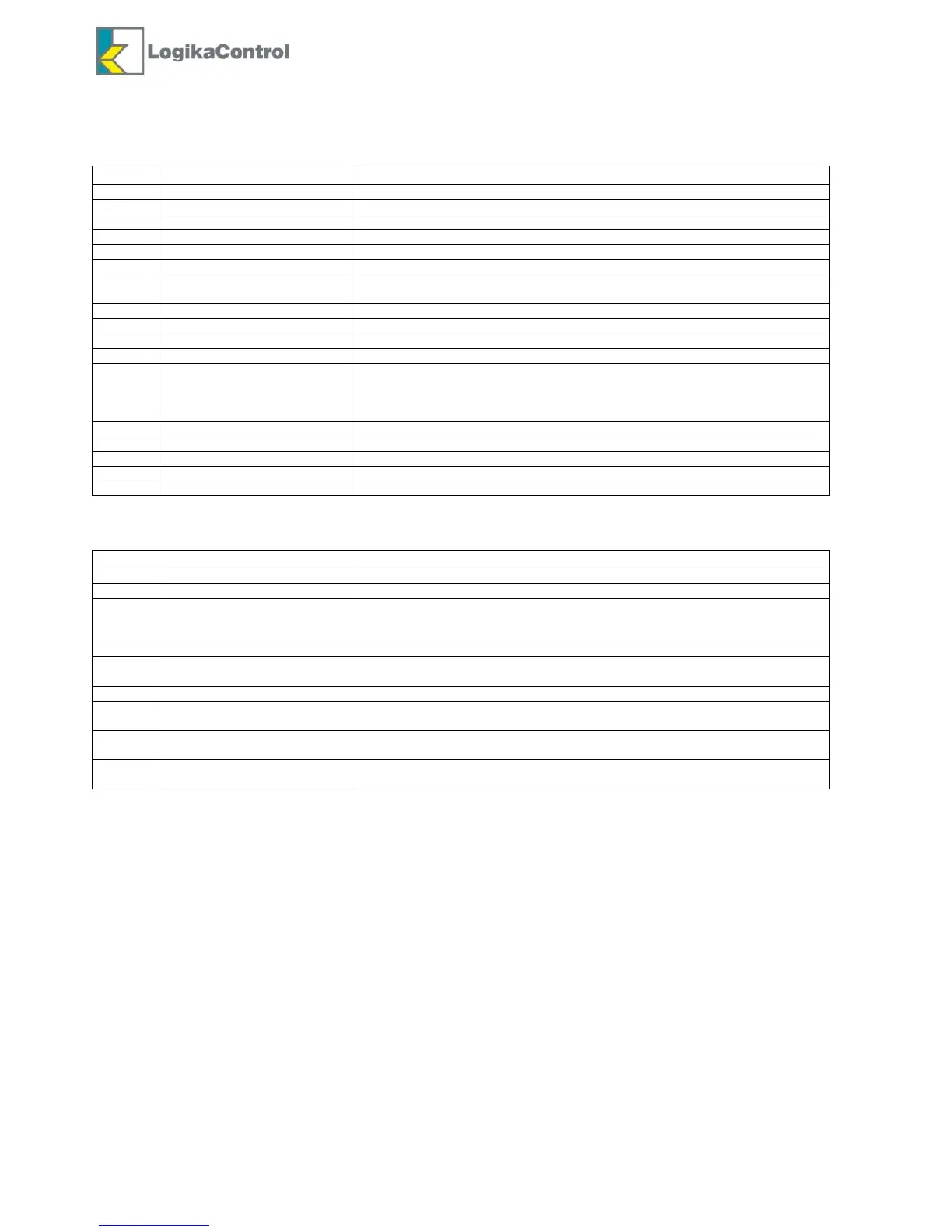

ALARMS

ALARMS WITH IMMEDIATE COMPRESSOR SHUT-OFF

Emergency stop button open (IN1)

One or more phase missed for over 300 m.s.

IN7 open (set as come door micro-switch)

Input relay fault drive open/closed (alarm managed with input enabled only

(C21=1/2))

Working pressure over set WP2

Air end temperature probe failure

Air end temperature over set WT1

Air end temperature lower than set WT5

Delta P (internal pressure – working pressure) over shut off set AP1 once the

timer C19.1 is over and air end temperature is over 45°C (alarm managed

when the aux pressure transducer is enabled into differential operation

(C19=2))

In case of power off and compressor set as manual restart

Safety pressure switch open (missing power to all digital inputs)

Parameter C12 = 3 (generic alarm)

Separator filter differential pressure switch open (IN6)

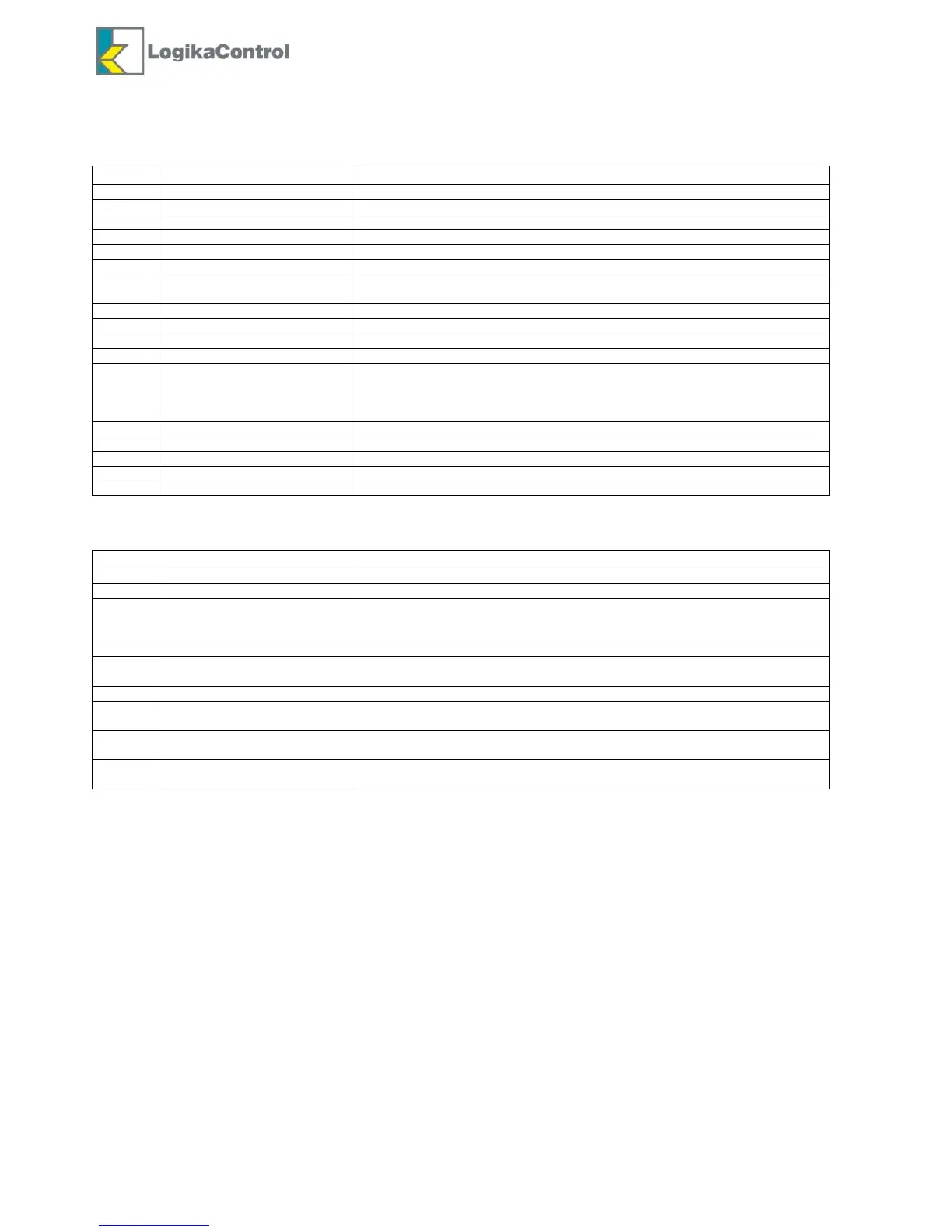

ALARMS WITH COMPRESSOR SHUT-OFF AFTER 30 SECONDS UNLOAD RUNNING

Working pressure transducer failure

Aux. Pressure transducer failure

Power supply to the controller lower than 9,5Vac and reset accepted when the

power goes over 10,6Vac.

It is not visualized in case it has been disabled in menu 4 Compressor SETUP

Timer CAF elapsed: this alarm is detected if the parameter Safety is set YES

Air end temperature over set WT2.

Reset once temperature is lower than WT2-5°C

Timer C—h elapsed: reset the related maintenance timer

In case compressor start/stop is operated via RS232 and the watchdog

function is enabled (see MODBUS protocol communication)

In case of inverter via RS485, shut off alarm detected (managed by inverter

connected via RS485 only (DR0>0))

No communication to inverter in case of connection via RS485 (managed by

inverter vua RS485 only (DR0>0))

NOTE:

Every time a shut-off alarm is detected, both relay set as alarm led DL1 are activated; the alarm message is stored into the

alarm list; once the cause of the alarm has been erased, push the button R to reset the message and start the compressor.

Loading...

Loading...