Chapter V Disassembly & Repair

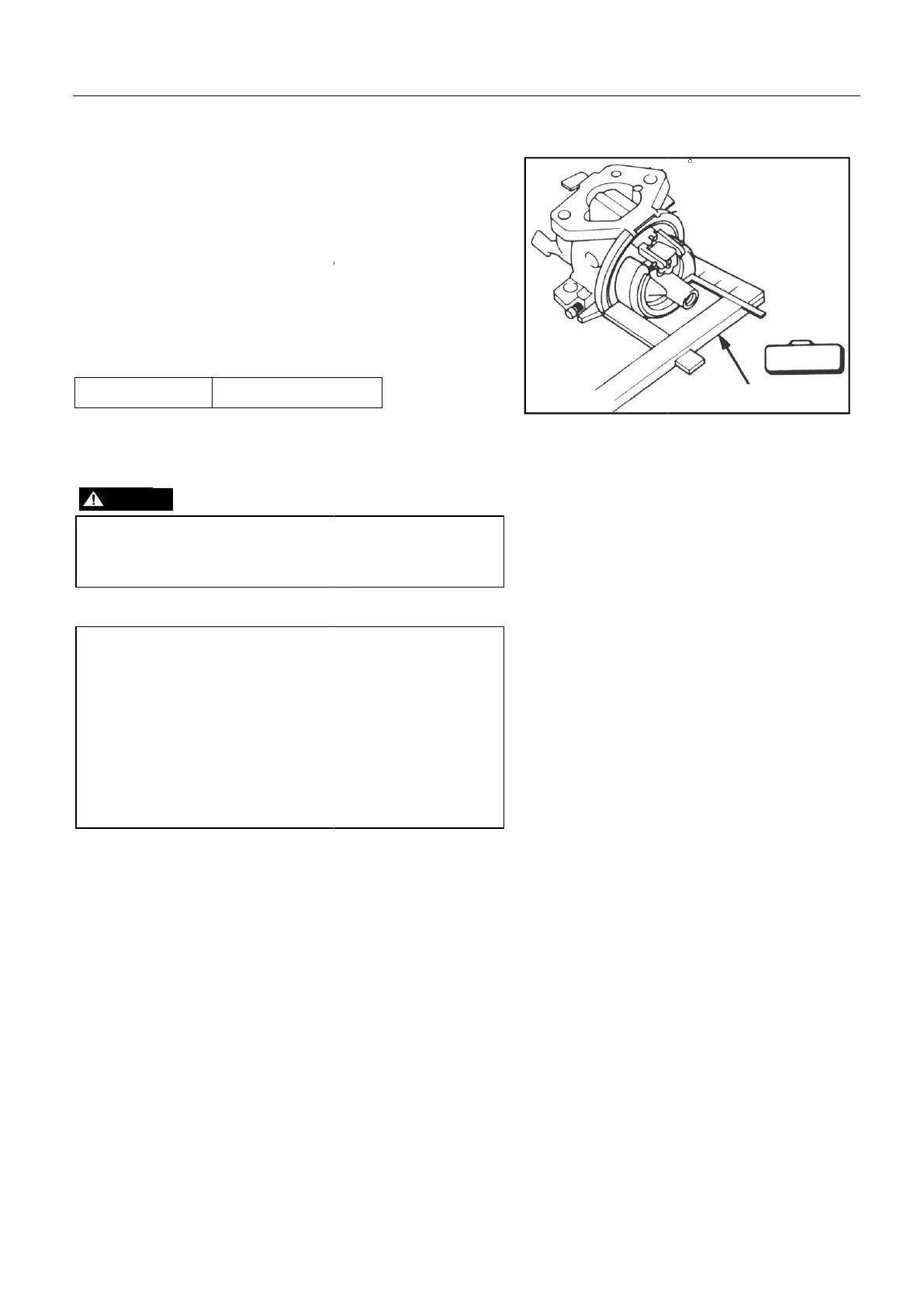

c. Check of float height

Place carburetor according to the figure and push in the float

with fingers.

When the float valve touches the float seat and

doesn’t compress, measure the dimensions between float and

the shell (height of the float).

When the height of float is inconsistent

d. Clean the carburetor

Note

1) Clean the carburetor with cleanser.

2) Blow in the

compression air to remove dirt in idl

installation.

Standard height

14

±1.5

Some

chemical solvents are of relatively

and may damage plastic parts such as the O

P

lease carefully read the Solvents Manual.

confirm, don’t

use the solvent to clean the carburetor. The

compression air of high pressure may also damage

carburetor. P

lease remove the dirt in

mouth with compression air of proper pressure.

W

hen using the compression air, to

protective spectacles or other protective equipment.

Warning

Chapter V Disassembly & Repair

- 42 -

Place carburetor according to the figure and push in the float

When the float valve touches the float seat and

the spring

doesn’t compress, measure the dimensions between float and

with the specified value, replace the float or float valve.

compression air to remove dirt in idl

e air jet, idle jet, air jet, main

jet, main nozzle, etc. prior to

chemical solvents are of relatively

-strong corrosivity

and may damage plastic parts such as the O

-ring and float.

lease carefully read the Solvents Manual.

Should you not

use the solvent to clean the carburetor. The

compression air of high pressure may also damage

the

the passage or pipe

mouth with compression air of proper pressure.

hen using the compression air, to

avoid injury, wear

protective spectacles or other protective equipment.

with the specified value, replace the float or float valve.

jet, main nozzle, etc. prior to

Float height gauge

Special tool

Loading...

Loading...