Chapter V Disassembly & Repair

- 55 -

Disassembly/assembly

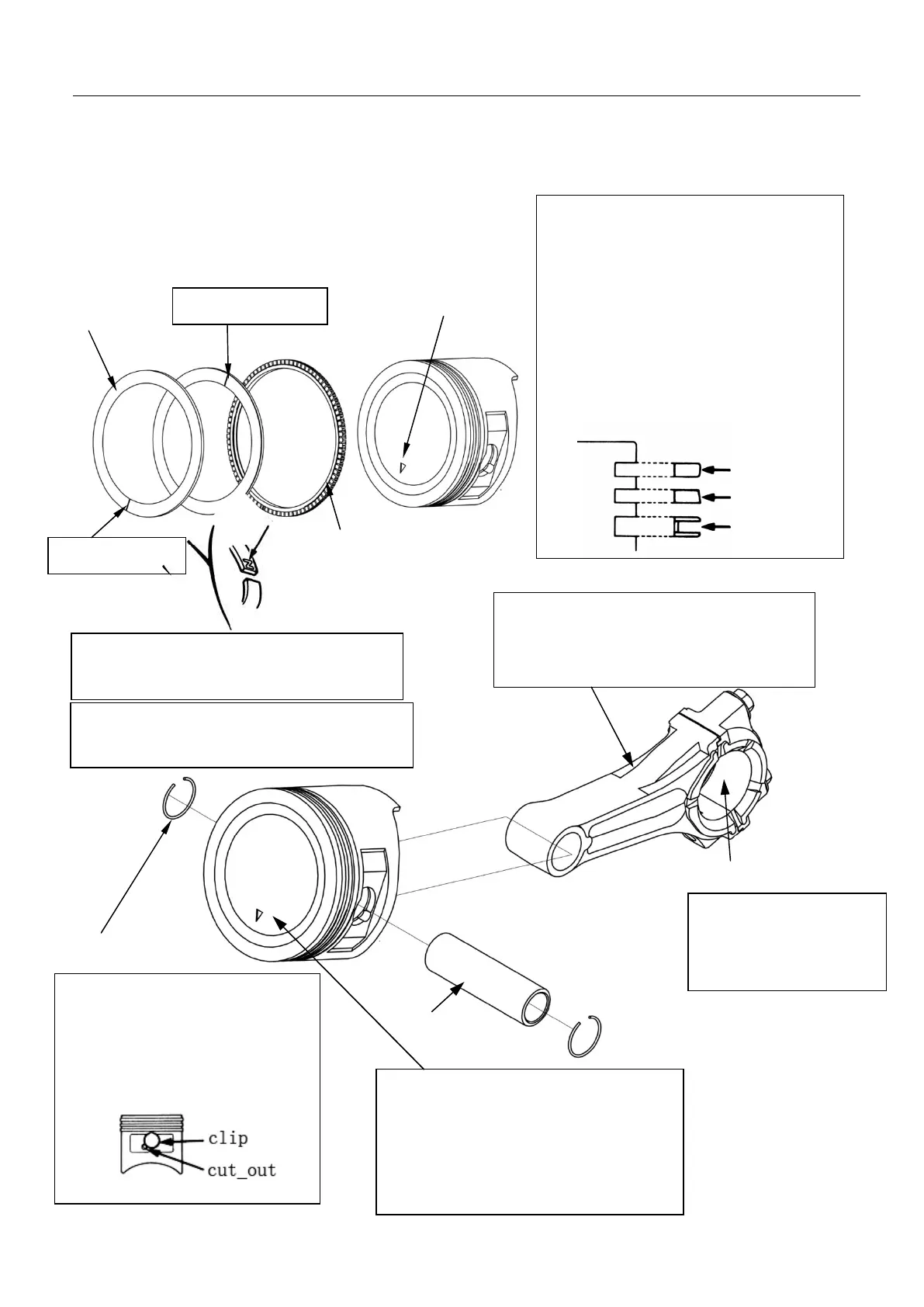

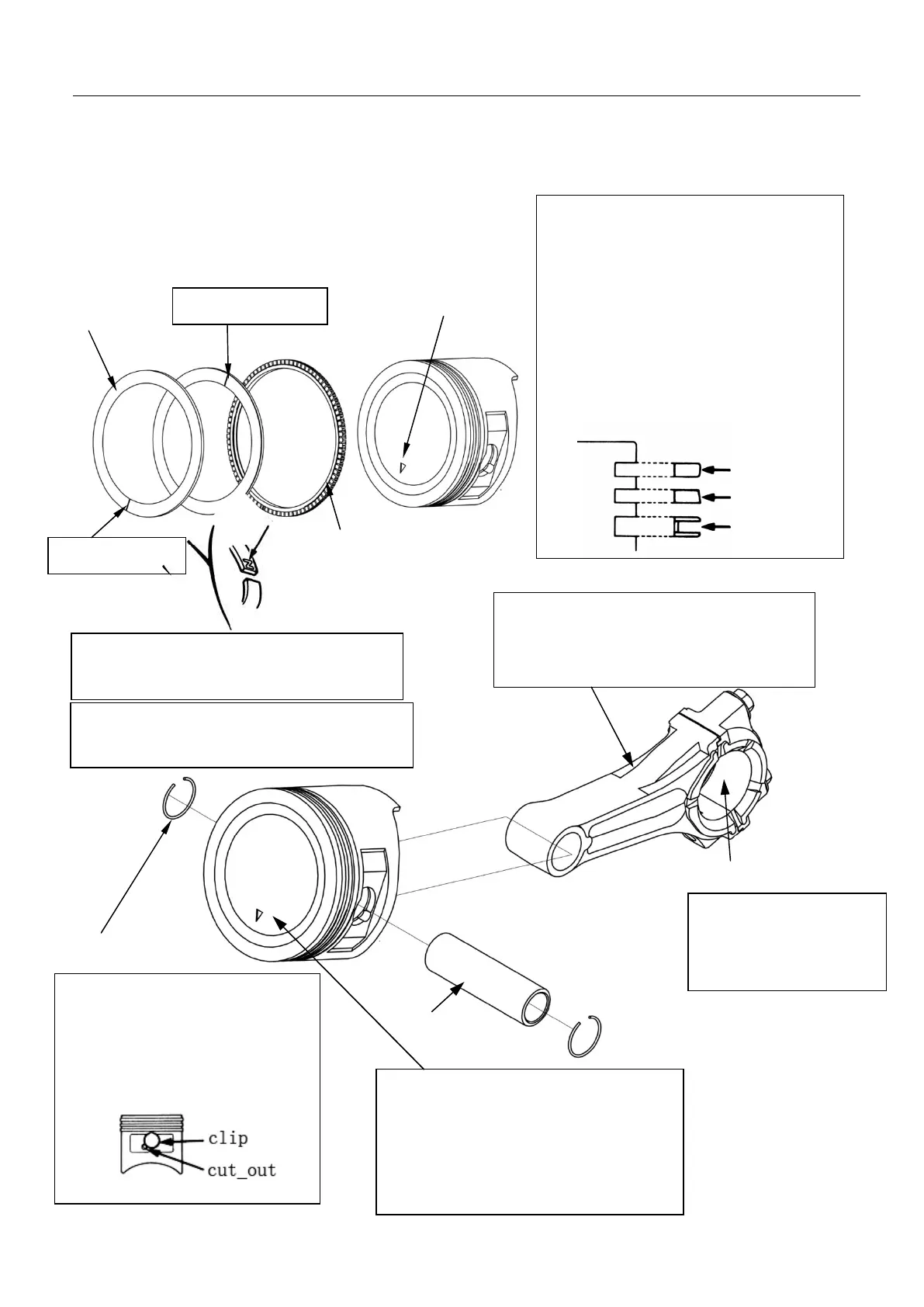

Piston and connecting rod

Ring 1

Ring 2

Ring 1

Opening of ring 1

Opening of ring 2

Ring 2

Oil rings

Note: point the “

▽

” at the top of the piston

to the opposite direction of rotation of the

crankshaft (seen from the engine output

end, the piston arrow of the right cylinder

is downward while the piston arrow of the

left cylinder is upward)

.

Note:

Openings of rings 1 and 2 shall be staggered

for 150° ~ 210°.

Note:

Opening of blade ring of oil ring shall be

staggered for 150°~ 210°.

Connecting rod

Steel wire retaining ring

Piston mark

Piston pin

Assembly:

Put one end to the slot of the piston,

and clamp the other end with the

long nose pliers; rotate and install it

into the slot. Don’t make the

opening of the clamp ring face the

gap of the piston pin.

Assembly:

p

oint the “ ” mark of the

piston to the same direction of that of the

connecting-rod boss during assembly while

the other is in the opposite direction.

Bigger end hole

Mark

Coat adequate lubricating

oil on the bigger end hole

of the connecting rod in a

full circle.

Assembly:

. Put upward the manufacturer’s mark

during assembly.

. Do not misplace the gas rings 1 and 2.

. Check if the piston ring can rotate

flexibly after installation.

. Avoid the direction of piston pin for each

opening of piston ring by staggering for

150° ~ 210°.

Loading...

Loading...