Chapter V Disassembly & Repair

- 59 -

Outer diameter of the crankshaft journal

Standard

Maintenance Limit

39.966-39.991 mm 39.906

Side clearance of the big end of connecting rod

Standard

Maintenance Limit

0.203-0.403 mm 1.0 mm

Oil-film clearance of big end of connecting rod (radial direction)

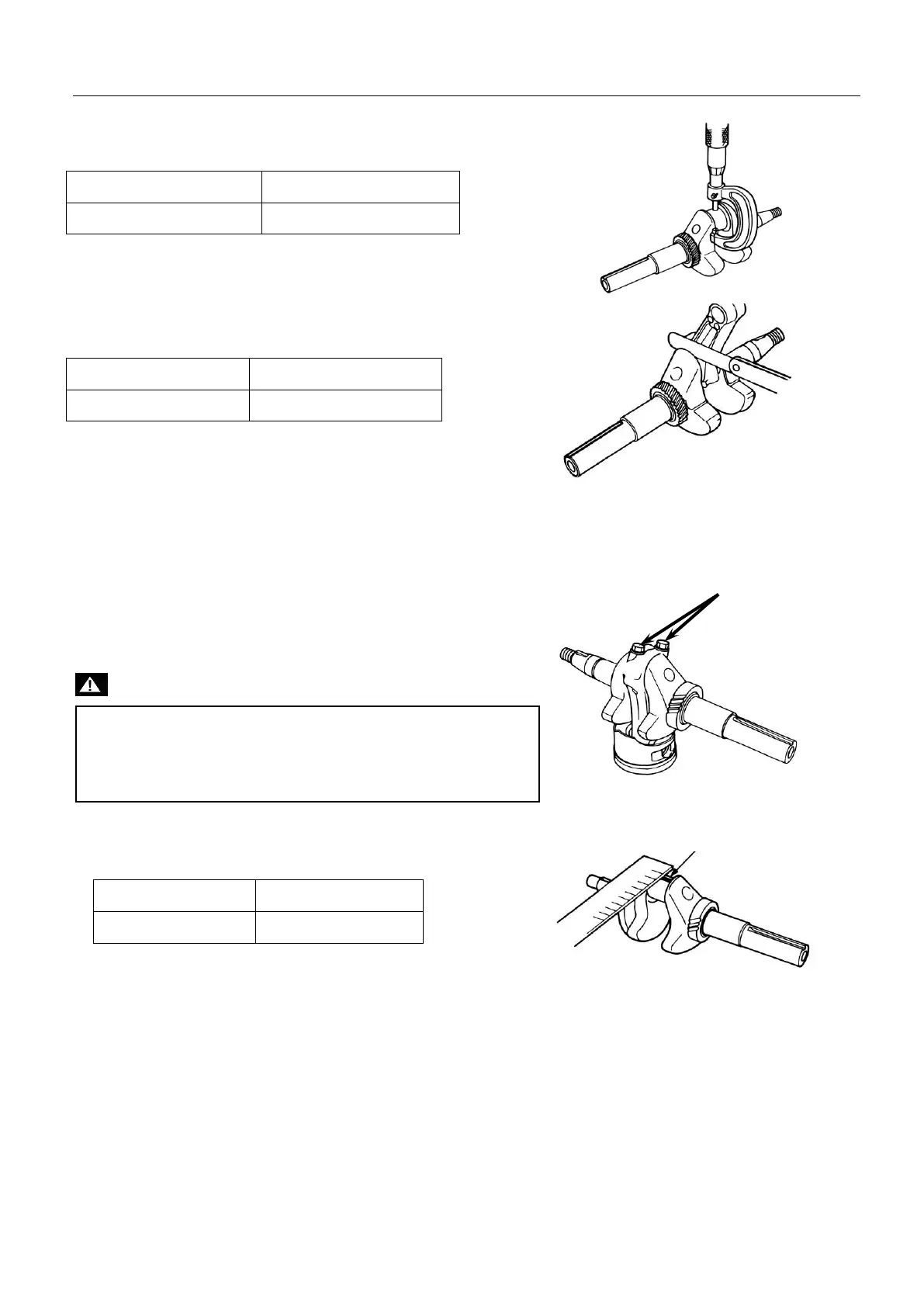

1) Clean the surface of crankshaft journal and the inside oil.

2) Set plastigauge on crank journal then assemble the connecting

rod, and fasten the bolt as per the specified torque.

Fastening torque: 12 N.m±1 N.m

Note

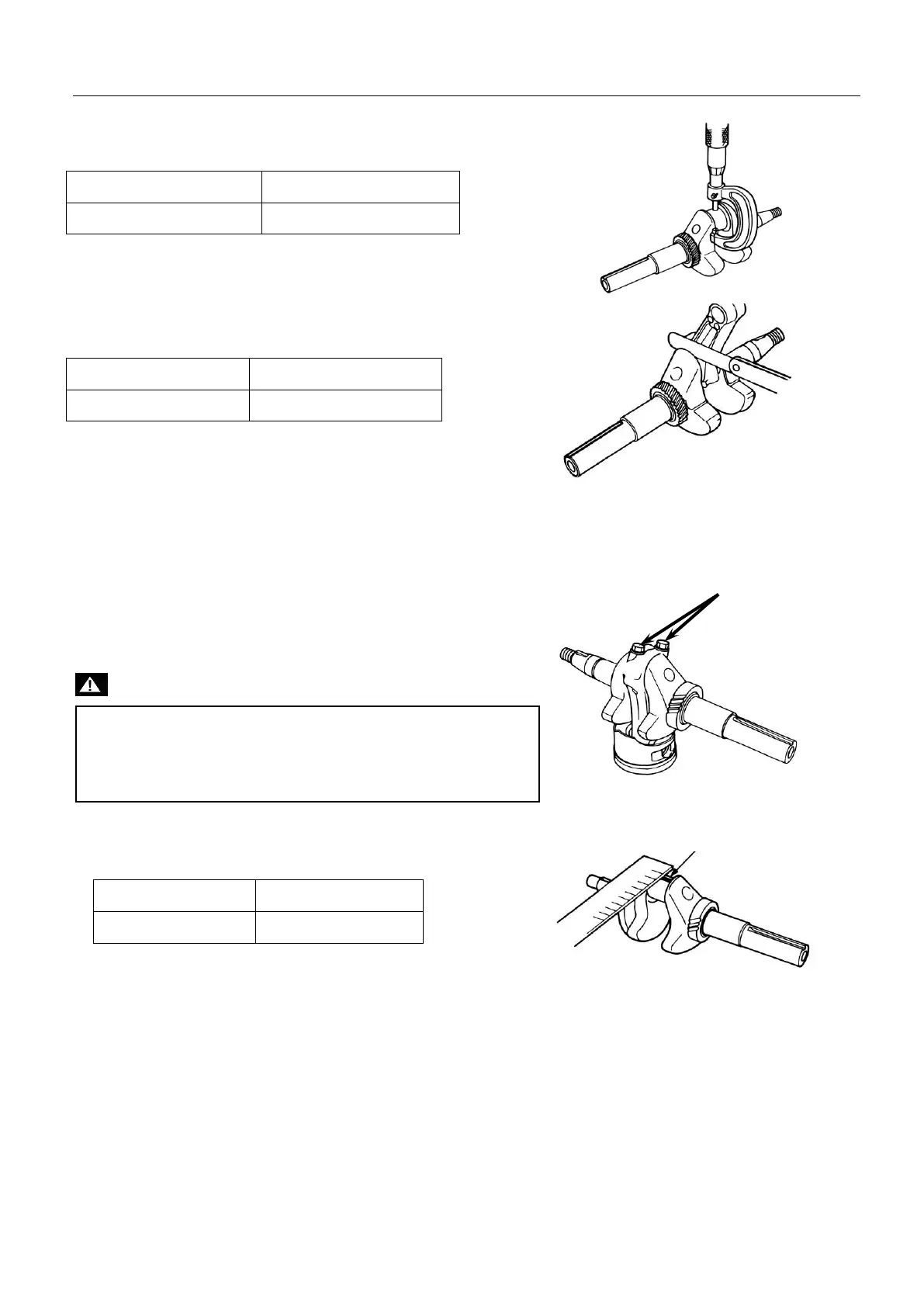

3) Disassemble the connecting rod and measure the thickness of

plastigauge.

4) When the clearance exceeds the maintenance limit, replace

the connecting rod and check the clearance again. If the clearance

still exceeds the maintenance limit after using new connecting

rod, grind the crankshaft journal and use the connecting rod less

than the standard value.

Standard Maintenance Limit

0.024-0.059 mm 0.115 mm

Don’t rotate the crankshaft when fastening the connecting-rod bolt.

Calibrate with torque wrench in N+1 way and conduct 100%

inspection to the crankshaft to see if it rotates flexibly.

Plastigauge

12 N.m±1 N.m

Loading...

Loading...