LORCH

Fund

amentals

of

the MIG/MAG welding process

16 Fundamentals of the MIG/MAG welding process

-~"'--'"~~~~~~~~~~~~~~~~

16.1

Princip

le

of

the MIG/MAG

welding

process

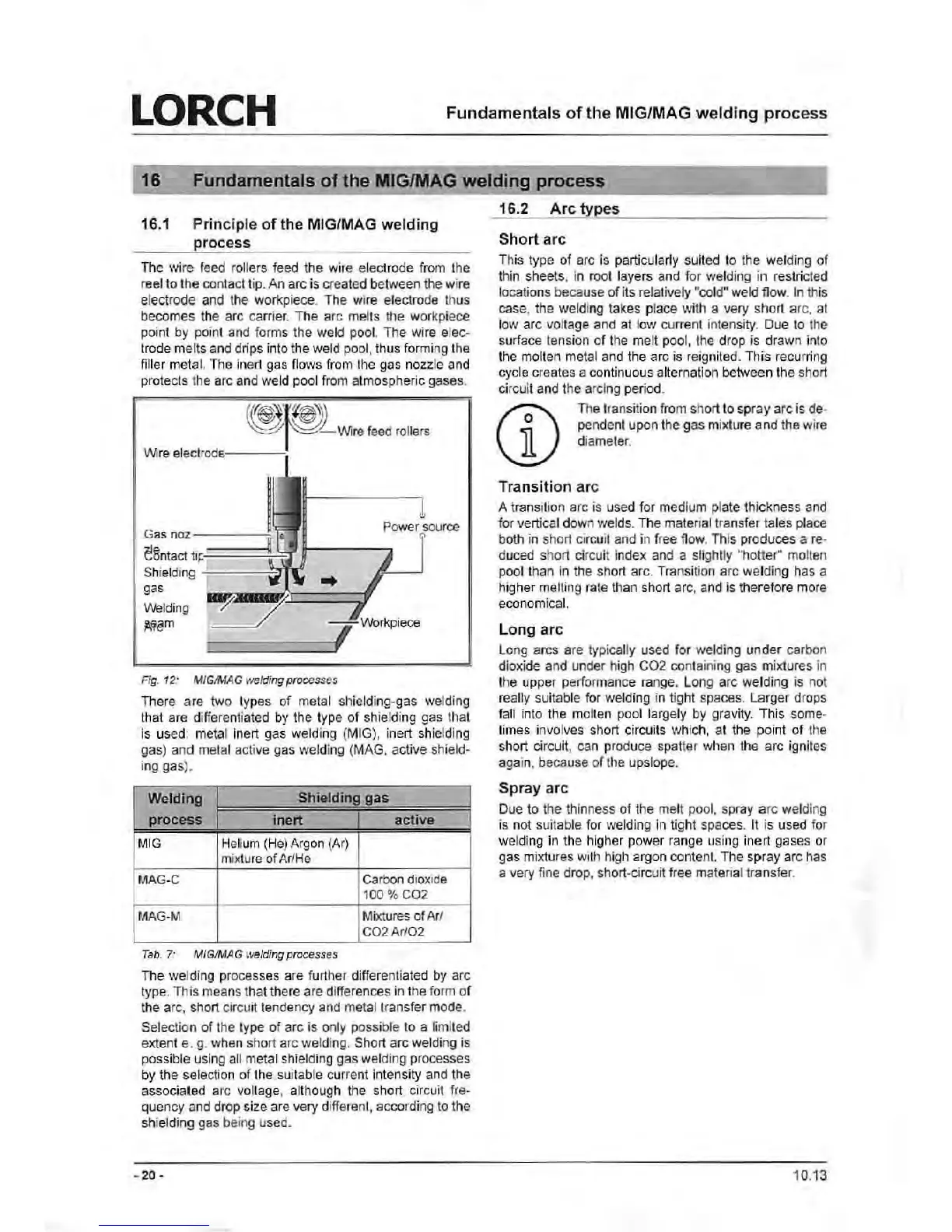

The wire feed rollers feed the wire electrode from the

reel to the contact tip.

An

arc is created between the wire

electrode

and

the workpiece. The wire electrode thus

becomes the arc carrier. The arc

melts the workpiece

point by point and forms the

weld pool. The wire elec-

trode melts a

nd

drips into the weld pool, thus fo

rm

i

ng

t

he

filler metal. The inert gas flows from the gas nozzle and

protects the arc and

weld pool from atmospheric gases.

Wire electr

od£--

-

-:

G

as

noz

--

-

---"

~Bntact

ti~:

-=

~

~~~

Sh

ielding

-,..--

-===--

___,.~

gas

Welding

,._flem

Fig. 12: MIG/MAG welding process

es

(!>

Powe

r source

t:I

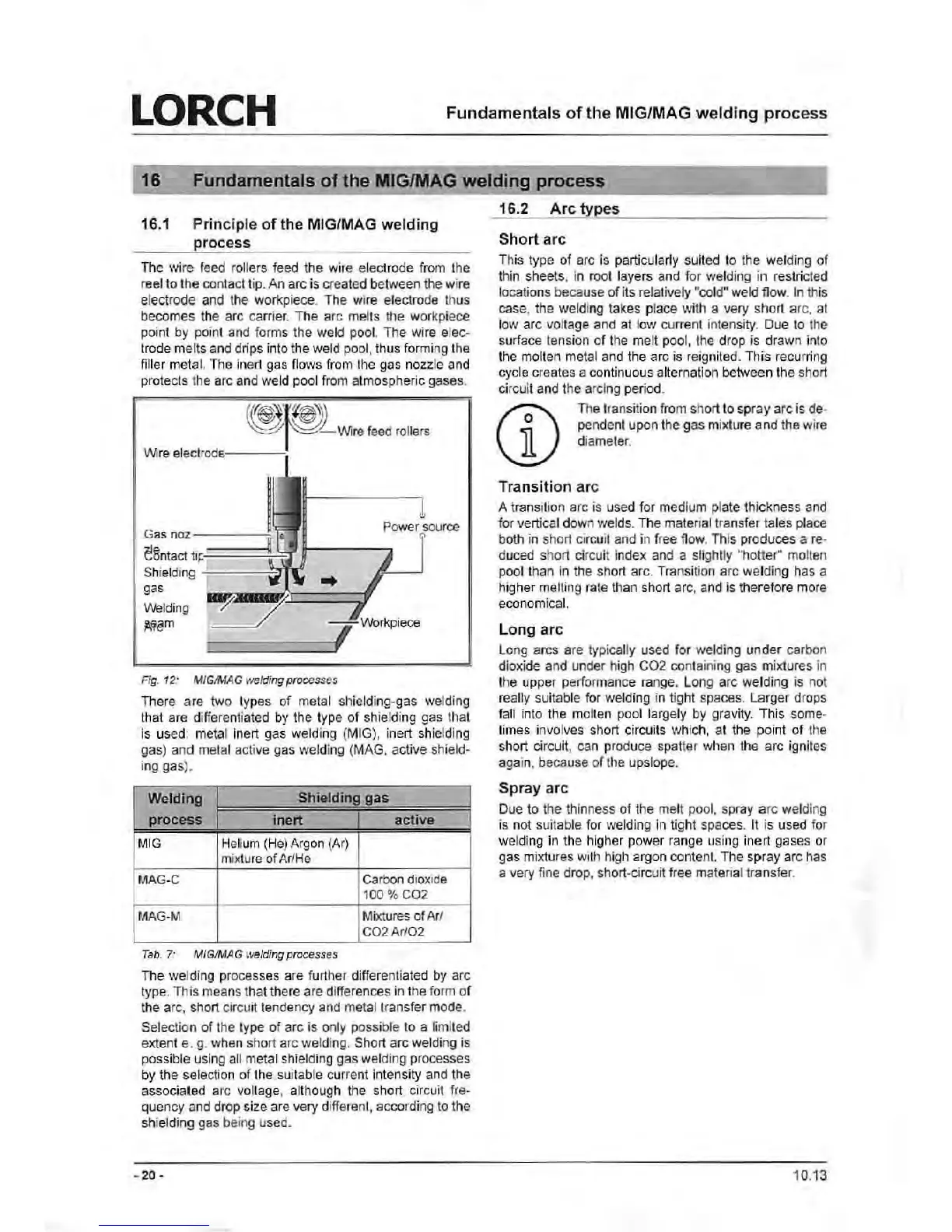

There a

re

two types

of

metal shielding-gas welding

that are diffe

re

nt

iated

by

the type

of

shielding

gas

that

is used:

metal inert gas welding (MIG), inert shielding

gas) and metal active gas weldi

ng

(MAG, active shield-

ing gas

).

Welding

Shielding

gas

process

inert

act

i

ve

MIG

He

li

um

(He)

Ar

gon

(Ar)

mixt

u

re

of

Ar/He

MAG-C

Ca

rb

on

di

ox

id

e

100 %

C02

MAG-M

Mixtures of Ar/

C02Ar/02

Tab.

7:

MIG/MAG welding processes

The welding processes are further differentiated by arc

type. T

his

means that there are differences

in

the form of

the arc, short circuit tendency and

metal transfer mode.

Selection

of

the type

of

arc is only possible to a limited

extent e. g. when short arc welding. Short arc welding is

possible using all metal shielding gas welding processes

by the

selection of the suitable current intensity and the

associated arc

voltage, alt

ho

ugh the short circuit fre-

quency and drop size are very different, according to the

shielding gas being use

d.

- 20 -

16

.2

Arc

ty

pes

Short

arc

This type of arc is particularly suited to the welding

of

thin sheets, in root layers and for welding in restric

te

d

locations because

of

its relatively "cold" weld flow.

In

th

is

case

,

the

weldi

ng

takes place with a very short arc. at

low arc voltage and

at

low cu

rre

nt intensity. Due to the

su

rf

ace tens

io

n of the

me

lt pool, t

he

drop is drawn into

the

mo

lt

en

metal and the arc is reignite

d.

This recurring

cyc

le

creates a continuous alternation between the short

circuit and the arcing period.

CD

The transi

ti

on from short to spr

ay

arc is de-

pendent upon the gas mixture and the wire

diameter.

Transiti

on

arc

A transi

ti

on arc is used for medium plate thickness and

for vertical down

welds. The materi

al

transfer tales place

both in short ci

rcu

it and in free flow. This produces a

re

-

duced short

ci

rcu

it index and a slightly "hotter"

mo

l

ten

pool than

in

the short arc. Tra

ns

ition arc welding has a

higher

melting

ra

te than short arc, a

nd

is therefore more

economical.

Long

arc

Lo

ng arcs are typically used for welding under carbon

dioxide and under high

C0

2 containi

ng

gas mixtures

in

the upper pe

rf

ormance

ra

nge. Long arc welding is not

re

ally suitable for welding in tight spaces. Larger drops

fall into the molten pool largely by gravi

ty.

This some-

times involves short circuits whic

h,

al

the point or the

short circuit,

ca

n produce spatter when the arc ignites

again. because of the

upslope.

Sp

ra

y arc

Due to the thinness

of

the melt pool, spray arc welding

is not suitable for welding

in

tight spaces. It is used for

welding in the high

er

power range using inert gases or

gas mixtures with high argon conten

t.

The spray arc has

a very fine dro

p,

short-circuit free material transfer.

10.13

Loading...

Loading...