LORCH

15 Welding basics

15.1

St

ick

electrode

wel

din

g

<--

-

----

Coated

st

ick electrodes are used for the widely-u

se

d

manual metal arc welding process (stick electrode

weld-

ing). The coating

of

the electrode melts off during the

weldi

ng

process together wi

th

the co

re

wire. T

he

coating

gene

ra

tes the shielding gas. Additionally the burning-

off coating compensates alloy elements. which are de-

stroyed

in

the molten pool. A slag layer forms on top

of

the welding seam. which covers and protects the cooling

welding se

am

against the a

ir

.

The coatings

of

the electrodes differ according to thick-

ness and type,

i.

e. chemical composition. This

re

sults

in

different welding properties and con

seq

uently different

applications for t

he

e'lectrodes. Types a

nd

nomenclature

a

re

defined in DIN EN 499 (forme

rl

y 1913).

-'---

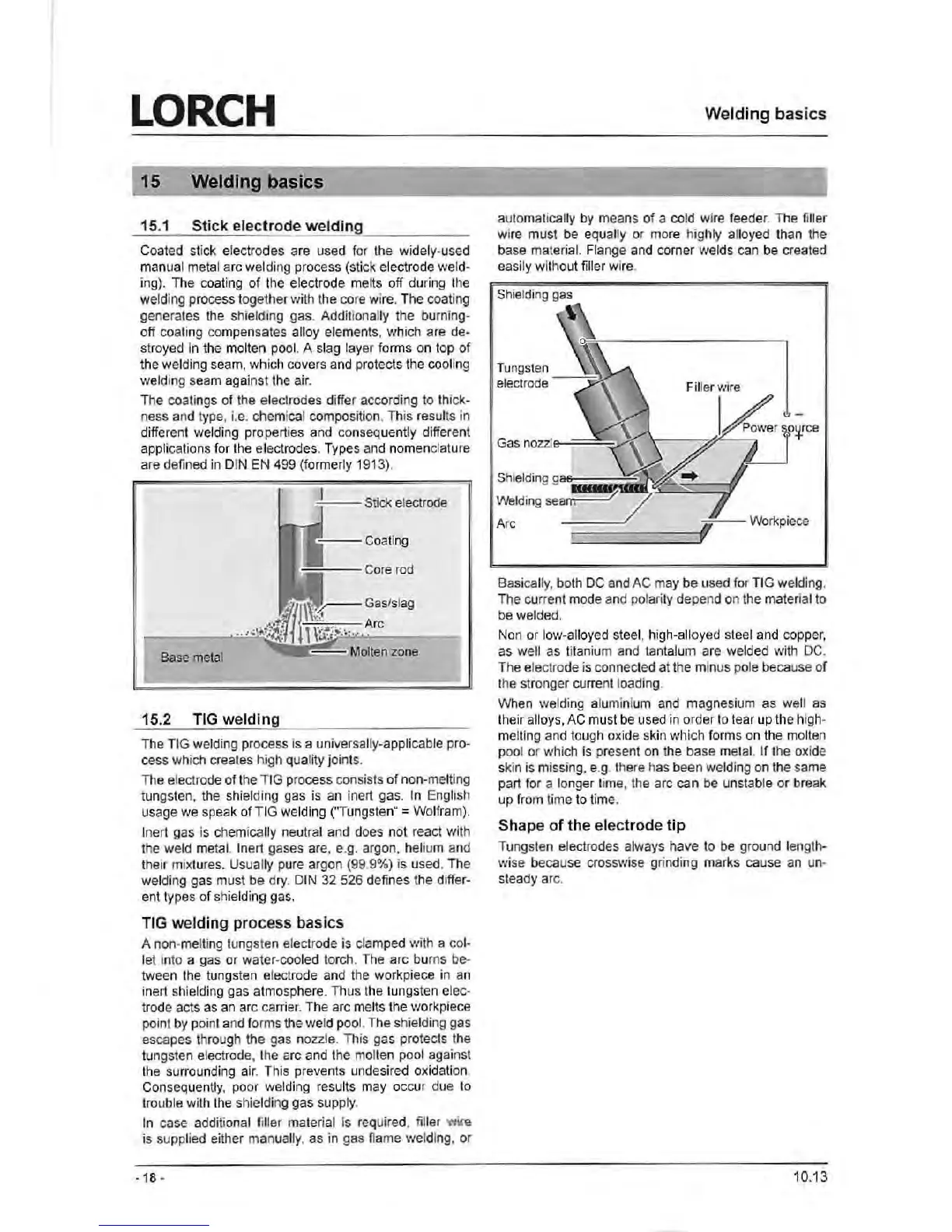

Stick electrode

Base

me

ta

l

15.2

TIG

weld

ing

The

TI

G welding process is a universally-applicable pro-

cess which creates high quality joint

s.

T

he

electrode

of

t

he

TIG p

ro

cess consists

of

non-melting

tungsten, t

he

shielding gas is an inert g

as

. In English

usage we

sp

eak

ofTIG

welding ("Tungsten" = Wolfram

).

Inert gas is chemically neut

ra

l and does not react with

the weld meta

l.

Inert gases are, e.g. arg

on

, helium and

their mixtures.

Usually pure argon (99.9%) is used. The

welding g

as

must be d

ry

. DIN 32 526 defines the differ-

ent types of shielding gas.

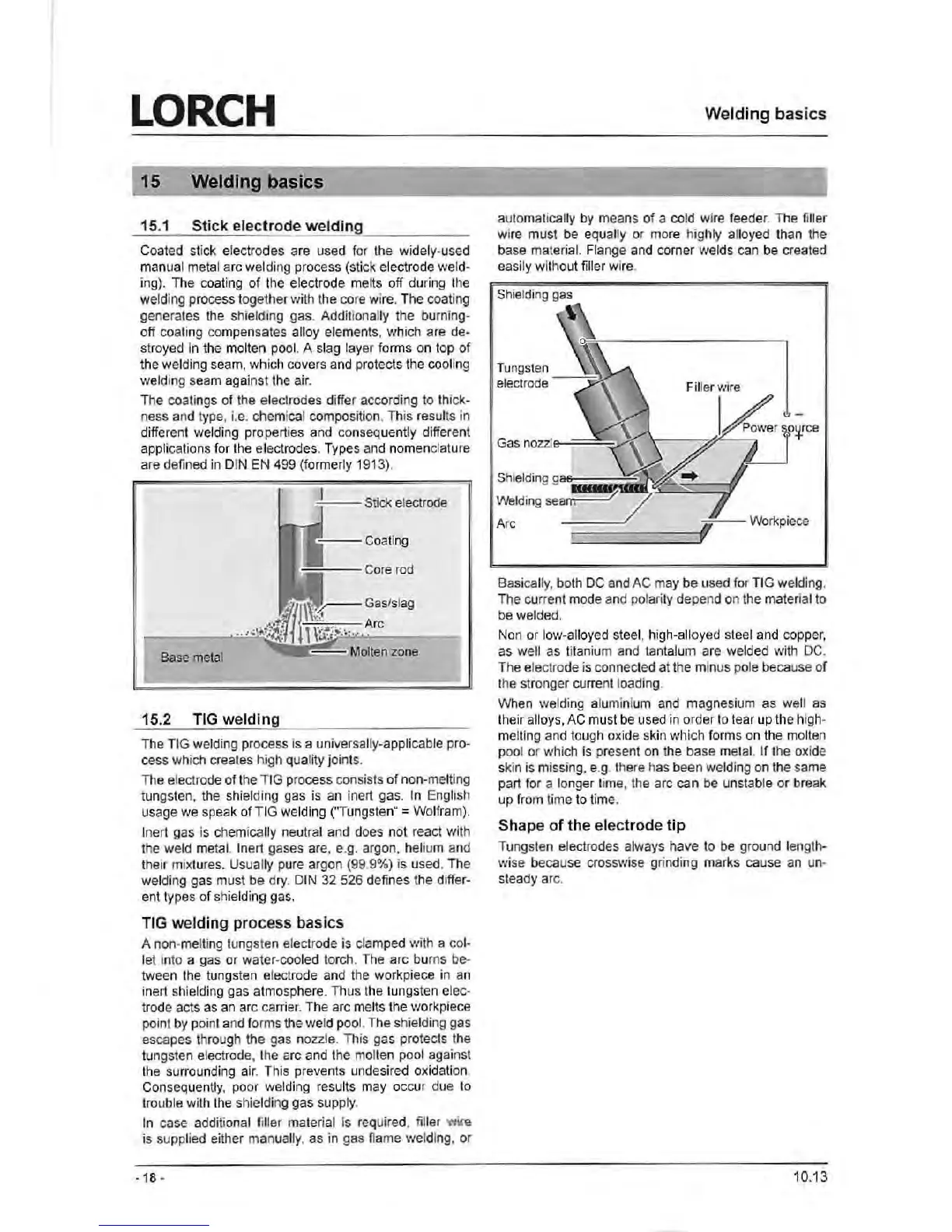

TI

G wel

ding

process basics

A non-melting tungsten electrode is clamped with a col-

let into a

gas

or water-cooled torch. The arc burns be-

tween the tungsten electrode and the workpiece in an

in

e

rt

shielding gas atmosphere. T

hu

s the tungsten elec-

trode acts as an arc carrier. The arc melts the workpiece

point by point and forms the weld pool. The shieldi

ng

gas

escapes through the gas nozzle. This gas protects the

tungsten electrode, the arc and t

he

molten pool against

t

he

su

rrounding air. This prevents undesired oxida

ti

on.

Con

seq

uently,

po

or welding results may occur due to

tro

ub

le with the shielding gas supply.

In case additional filler material is required. filler

~1\re

is supplied either manually, as

in

gas name

we

ldin

g,

or

-18

-

We

lding

bas

ic

s

automatically

by

means of a cold wi

re

feeder. The filler

wire must be equally or mo

re

highly alloyed than the

base mater

ia

l.

Fla

nge and corner welds can be crea

te

d

easily without filler wire.

Sh

ieldi

ng

gas

B

as

ically, both DC and AC may be used for TIG welding.

The current mode and pol

ar

ity depend on the material to

be welde

d.

No

n or low-alloyed steel, high-alloyed steel and copper,

as

well as titan

iu

m a

nd

tantalum are welded with

DC

.

The electrode is connected at the minus pole because of

the stronger

cu

rrent loading.

When welding aluminium and nnagnesium as well

as

their a

ll

oys,

AC

must be used in order to tear up the high-

melti

ng

and tough oxide skin which forms on the molten

pool or which is present on the base

metal. If t

he

oxide

skin is missin

g.

e.g. there has been w

el

ding on the same

part for a longer tim

e,

the arc can

be

un

sta

ble or break

up from time to

ti

m

e.

Shape of the electrode

tip

Tungsten electrodes always have to be ground length-

wi

se

because crosswise g

ri

nd

ing marks cause an un-

steady arc.

10

.13

Loading...

Loading...