Puesta en marcha

- 65 -

01.21 909.2669.9-02

Ajuste del ID del soplete

En cada soplete de la serie i-LTG/i-LTW se encuentra almace-

nado un número de identicación de soplete. A este ID de

soplete se encuentra asociada la capacidad de carga máxima

del soplete. Con la protección de soplete activada (parámetros

secundarios “tPr” = On), en el modo de operación WIG, solo

puede ajustarse en el aparato de soldar una corriente de sol-

dadura con la máxima capacidad de carga del soplete.

El ajuste del ID del soplete es necesario p. ej. al cambiar la

placa del soplete.

Seleccione el menú nº C00 en el menú especíco del usua-

rio.

Ajuste en el regulador giratorio 41 el ID del soplete necesa-

rio, basándose en la tabla de ID de soplete.

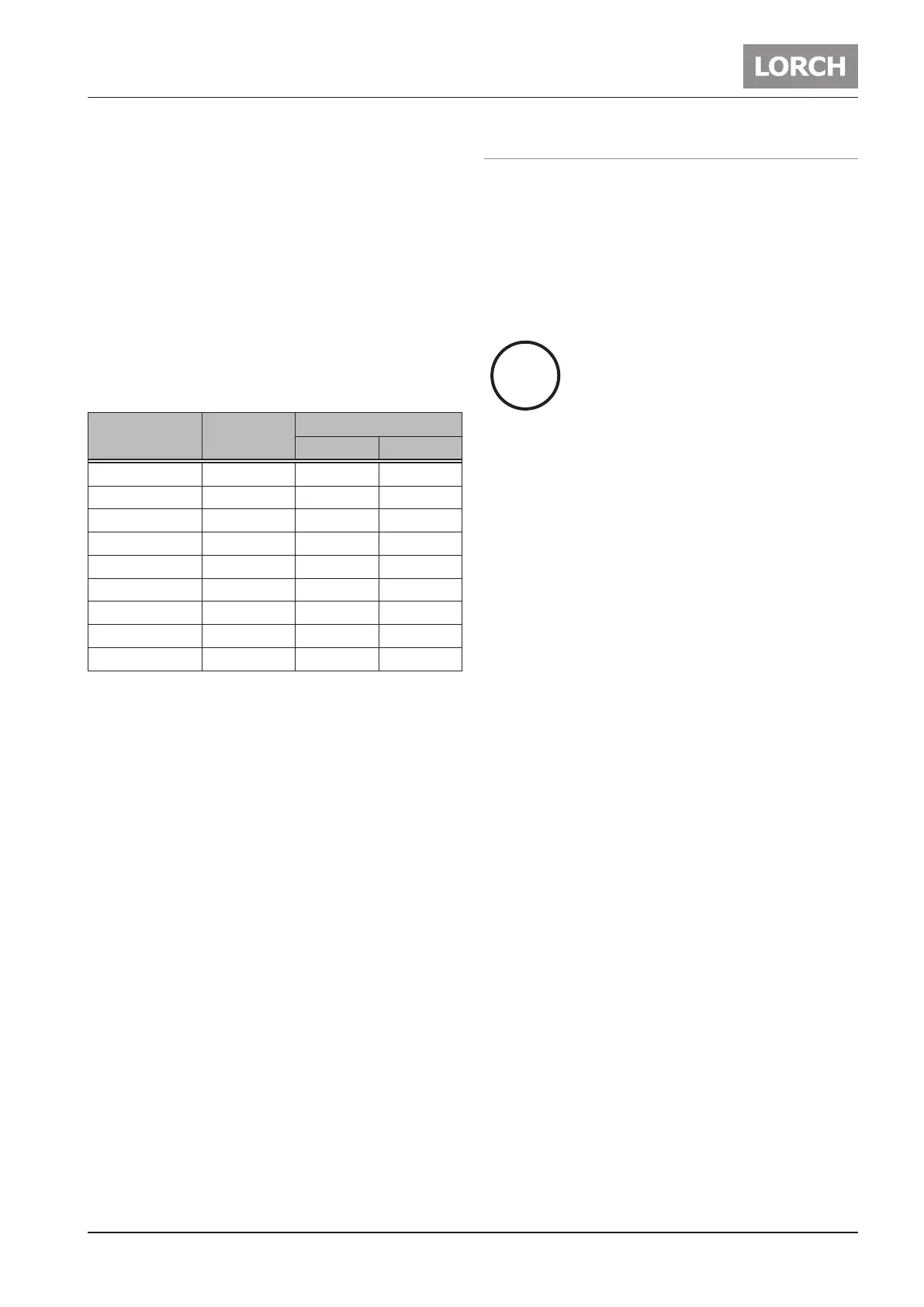

Tipo de soplete

ID de so-

plete

Capacidad de carga

CC CA

i-LTG 900 9 125 A 80 A

i-LTG 1700 17 150 A 120 A

i-LTG 2600 26 200 A 160 A

i-LTG 2800 28 300 A 250 A

i-LTW 3000 30 320 A 220 A

i-LTW 1800 18 350 A 250 A

i-LTW 1800sc 19 400 A 320 A

i-LTW 2000 20 220 A 165 A

i-LTW 4500 45 450 A 360 A

Tab. 6: ID de soplete

Para guardar, pulse la tecla que se encuentra a la derecha

bajo el parámetro principal 48.

9 El ID de soplete ajustado se transere al soplete.

14.6 Funciones especiales

Test de gas, test de panel de mando

Pulse simultáneamente la tecla superior derecha Modo de

operación 47 y la tecla inferior derecha Parámetro princi-

pal 48; el test de gas se iniciará en aprox. 30 segundos. Al

mismo tiempo se iluminarán brevemente todos los LEDs y

la indicación de 7 segmentos.

Pulsando de nuevo ambas teclas el test de gas nalizará.

Reset principal

Todos los parámetros de soldadura y secunda-

rios retomarán el ajuste de fábrica (Función de

reset principal)

Pulse la tecla Soldadura 30 arriba a la izquierda y mantén-

gala pulsada.

Al mismo tiempo, pulse brevemente la tecla

Parámetro principal 48 abajo a la derecha.

9 LED y las indicaciones de 7 segmentos se iluminan breve-

mente.

i

Loading...

Loading...