page 7

Pc-board DK-MAPRO

The pc-board DK-MAPRO is responsible for the welding sequence and is managing the process control of the

V-Series

(MAPRO = MAster-PROcess)

Functions

- Logicfunctions of the welding process

- generating and monitoring supply voltages

- driving powerup-relais

- driving power unit/units

- driving ignition device

- monitoring control and operating elements (DK-ACI40/DK-DCI40, remote control, torch buttons)

- driving solenoid valve

- driving fans

- driving waterpump

- monitoring owmeter

- monitoring mains- and output voltage

- generating signal „welding current on“

- managing communications between PC and machine

- managing and storage of all welding parameters

- CAN-bus

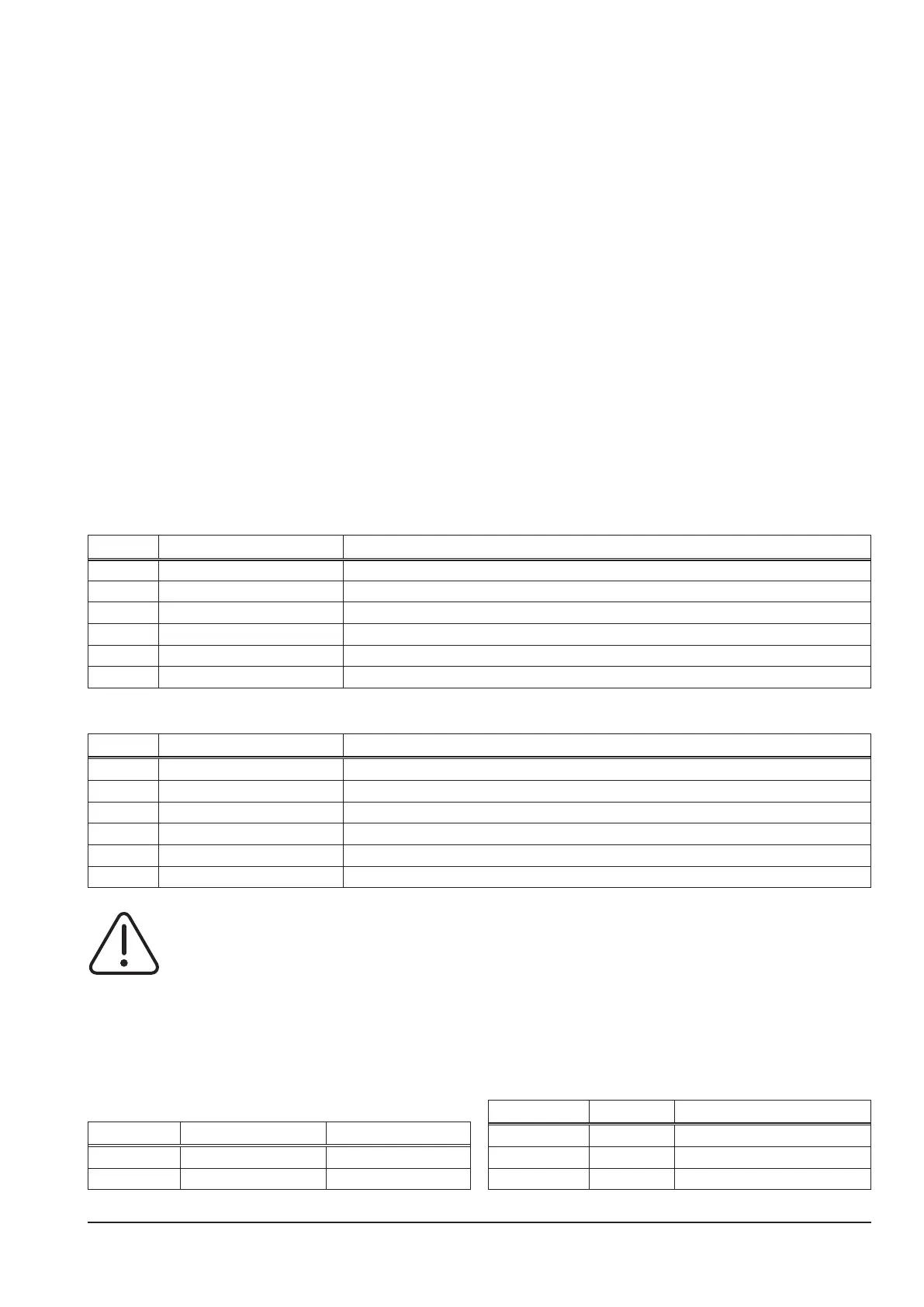

LEDs :

normal

LED state meaning

1 (green) ashing (half freq. of LED5) CPLD ok

2 (red) o Digital Signal Processor (DSP) ok

3 (green) on supply voltage 3.3V ok

4 (red) o Microcontroller ok

5 (green) ashing DSP is working

6 (green) ashing Microcontroller is working

malfunction

LED state meaning

1 (green) never on CPLD not working

2 (red) on DSP not working

3 (green) o supply voltage 3.3V missing : check 18V~ of control transformer X9/1 X9/2

4 (red) on Microcontroller not working

5 (green) never on DSP not working

6 (green) never on Microcontroller not working

If the LEDs are indicating a malfunction which can not be relieved by switching the machine o and

on again, it is recommended that the pc-board DK-MAPRO is exchanged.

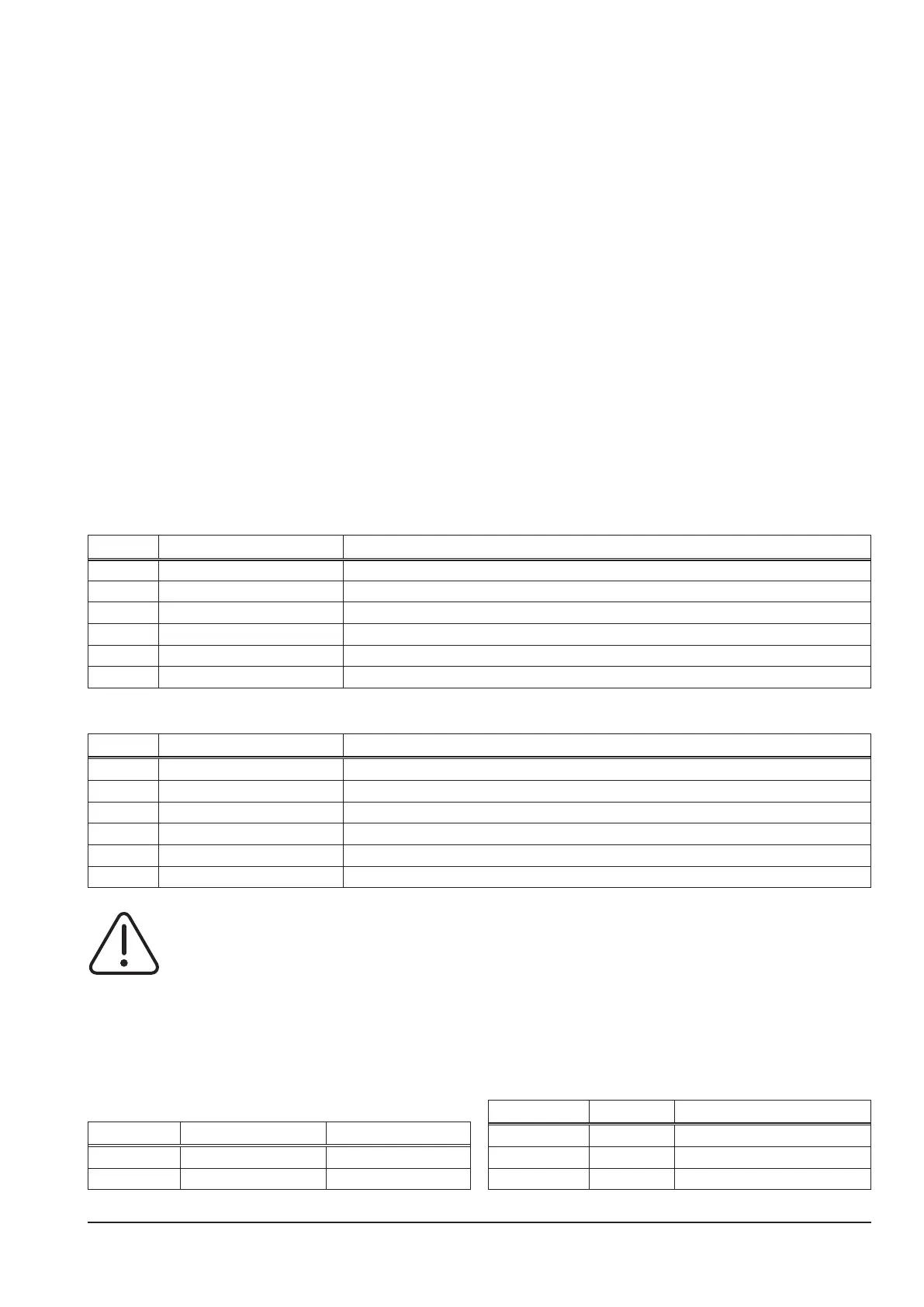

DIP switch

The DIP switches 1-3 are needed for pro-

gramming the DSP (Process) via serial port.

The DIP switch 4 is set due to the type of

housing as V mobile or V driveable.

DIP switch ON OFF

1-3 serial program. mode normal operation

4 cong. V mobile cong. V (driveable)

Overview fuses

fuse value [A] safeguarding

Si 6 1 fans (power unit)

Si 7 2,5 cooling unit (pump)

Si 11 1 cooling unit (fans)

Loading...

Loading...