14

v130207

BERNT LORENTZ GmbH & Co. KG Kroegerskoppel 7, 24558 Henstedt-Ulzburg, Germany, Tel. +49 (0) 4193 7548 - 0, Fax - 29, www.lorentz.de

Errors excepted and possible alterations without prior notice.

4.6 Maximum RPM Setting

All PS controller offer the option of reducing the maxi-

mum speed of the pump.

This RPM control reduces the maximum speed (RPM

limit) to as low as about 30 %. It will NOT reduce the

starting or low-light performance. The pump uses less

power when it pumps less water.

Reasons to reduce the maximum RPM:

1. To prevent over-pumping a limited water source.

See section 5.8, Utilizing a Low-Production Water

Source

2. To improve energy and water-source manage-

ment in a battery system where slow pumping is

adequate to meet the demand

3. To limit the back-pressure (and prevent possible

pump overload) when pumping into a direct-

pumped irrigation system, a filtration system, or

an undersized pipeline.

How to reset the Maximum RPM setting:

1. Remove the bottom end of the PS controller

enclosure (the end with the conduit openings)

2. Locate the adjustment knob shown in the photo

below (circled)

3. In most cases, the knob will be at the standard

factory setting full clockwise as indicated by

“setting #1” illustrated below. Turn it counter-

clockwise to the desired setting. The exact posi-

tions may vary from this illustration. Follow the ink

marks on the controller.

CAUTION If you perform this

adjustment, record the setting on

the System Report Form, see

section 13. If flow testing is done

in the future, the result may lead to a wrong

conclusion if this adjustment is not accounted

for.

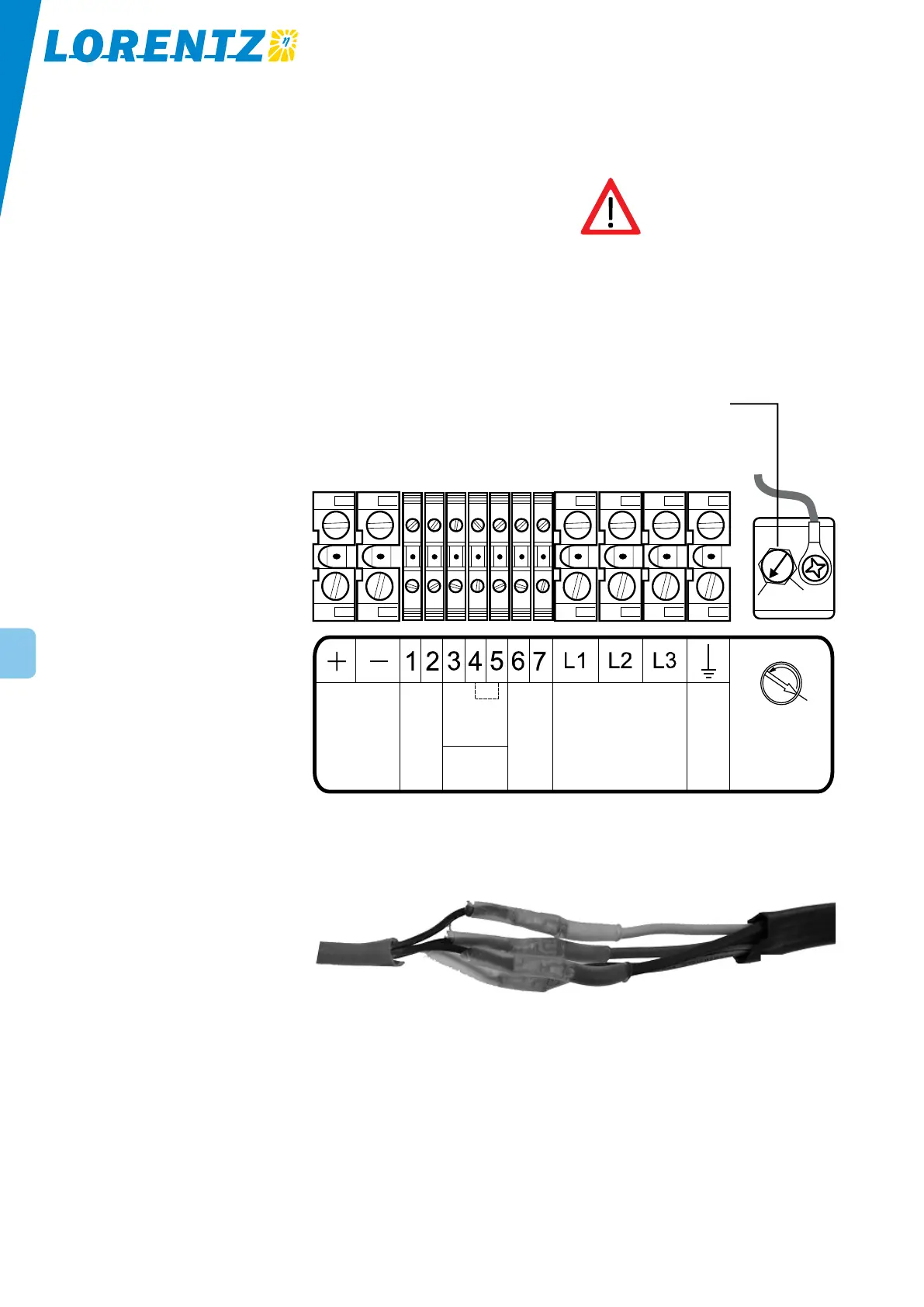

Power In

Pump

Max. RPM

Setting

Low-water sensor probe

connect to bypass

For factory

testing only

To reverse direction,

reverse any two wires

Factory setting:

Maximum

GROUND

Remote

Float

Switch

NO

COM

NC

Figure 11: Terminals inside the PS controller

Maximum RPM

Setting Knob

4.7 Submersible Pump Cable and Splice

Selection of cable Use only an approved type of

submersible well pump cable, the same type that is used

for conventional AC pumps. It is available from your

pump supplier or installer, or a local water well supply

distributor. You need 4-conductor cable. It is often called

“3-wire-with-ground” because it has 3 power wires plus

a ground wire. To determine the minimum required wire

size, refer to the Systems Sizing Table.

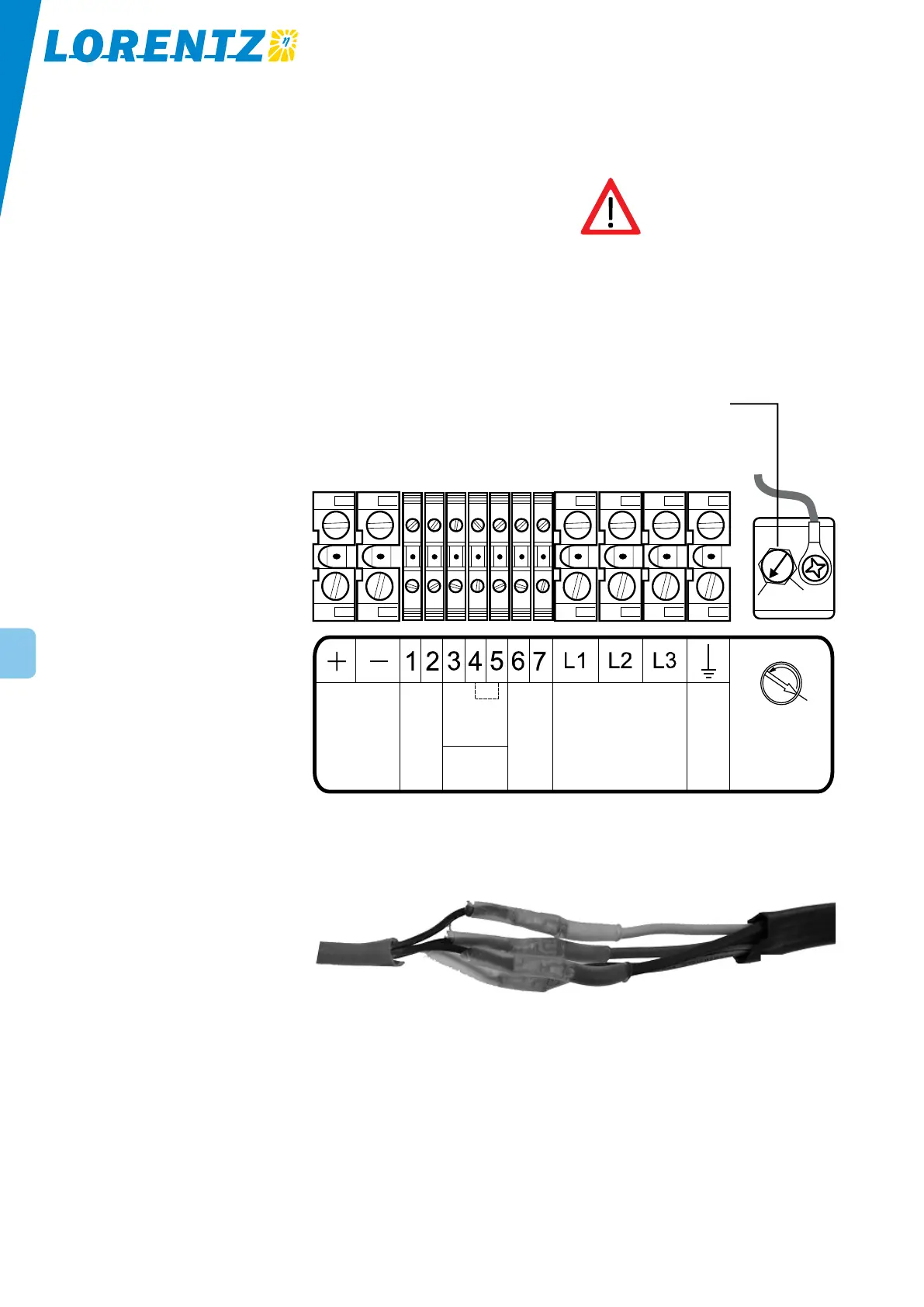

Submersible Splice A splice kit includes crimp connectors

to join the copper wires, adhesive heat-shrink tubing,

and instructions. If the drop cable is too large to fit in

the crimp connector, cut off some of the wire strands.

Use a crimping tool, and observe that the wires are held

very securely.

motor leader cable

wires spliced with

adhesive heat-shrink tubing

drop cable

Figure 12: Cable splice

Loading...

Loading...