16

v130207

BERNT LORENTZ GmbH & Co. KG Kroegerskoppel 7, 24558 Henstedt-Ulzburg, Germany, Tel. +49 (0) 4193 7548 - 0, Fax - 29, www.lorentz.de

Errors excepted and possible alterations without prior notice.

Potential problems with the low-water probe

in surface water The probe has a moving float. It

is highly resistant to deposits and debris. However, it

may stick under some extreme conditions, especially

from algae or water creatures (snails, etc.) that may be

present in surface water.

Possible solutions are:

1. Hang the probe independently of the pump and

pipe (clamped to a weight, but not to the drop

pipe). This way, it can be pulled up for inspection

or cleaning without the need to pull the pump.

(This may not be feasible if the well casing is

smaller than 6 in.)

2. Pull the probe out periodically (with the pump if

necessary) for testing and inspection. The pump

should stop at the moment the probe leaves the

water.

3. Wrap the probe in a protective screen (fiberglass

window screen, for example). Substitute a differ-

ent type of float switch. You can use any switch

that makes contact on rise (normally open).

WARNING Running completely dry

will damage the pump and void

the warranty. The purpose of the

probe system is to sense the loss

of water and turn the pump off

before it can run dry.

CAUTION The low-water probe

must be positioned vertically,

within 10°. If the pump is NOT to

be installed vertically, find an

alternative way to mount or suspend the probe,

so that it is higher than the pump, and in a

vertical position.

CAUTION Do not use a pressure

switch with a “low water cutout”

or “loss of prime” feature as a

method of dry-run protection. A

helical rotor pump will maintain pressure as it

runs dry, so this method will not work reliably.

For pressure switch information, see section

4.13, Pressurizing Systems

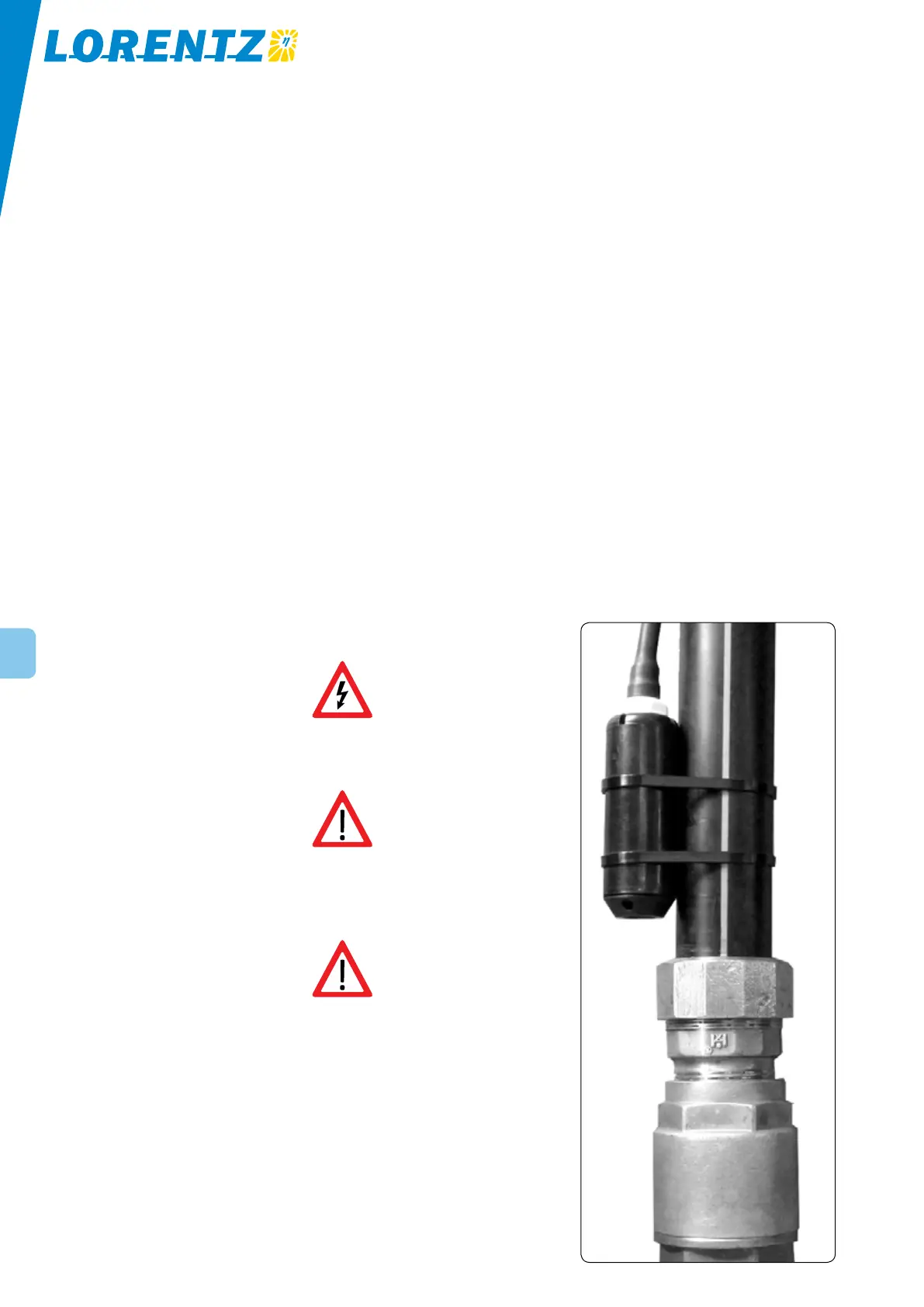

Figure 13: Low-water probe installed in the

standard position, for a pump that is positioned

vertically

4.10 Low-Water Probe for Dry-Run Protection

Installation The probe is packed with two stainless

steel hose clamps. For a pump that is to be installed in

a vertical position, clamp it to the pipe just above the

pump outlet, as shown in the photo. Splice the two

probe wires using the splice kit components that are

packed with the probe. The assembly procedure is the

same as the main pump splice.

If you are NOT using the well probe, it must be

bypassed. Connect a short wire between the probe

terminals in the junction box (terminals 1 and 2). Do this

only if you feel certain about the reliability of the water

source. Wire size: #18 AWG (1 mm

2

) or larger.

Principle of operation The probe contains a me-

chanical float with a magnet inside. When the probe is

submerged, the float rises, and the magnet actuates a

switch. The switch closes (makes contact) to indicate the

presence of water. The switch is sealed, so the contacts

never touch the water.

If the water level drops below the probe, the float drops,

and the switch opens (breaks contact). The controller

will stop the pump and the “Low-Water OFF” light

will indicate. When the water level recovers and switch

closes again, the controller will delay the restart for 20

minutes. This gives time for the water level to recover.

To force a quick restart, turn the controller off, then on

again.

NOTE Pumps made before October 2003 may

have a different type of probe, with wet

electrodes. Either type can be used with the PS

series controllers.

The Low Water-OFF light flashes slowly for the

remainder of the day, even if the water recovers and

the pump restarts automatically. This tells you that the

water source ran low at least once since the power was

disrupted (or sun went down). To turn the light off, reset

the controller by turning it off/on.

Loading...

Loading...