25

5.7 Coping with Dirty Water Conditions

PS pumps have good resistance to quantities of sand

and fine sediment that can normally occur in a well.

However, any amount of abrasive material will reduce

the life of this pump, like any other pump. Extreme

sediment can cause the pump to stick. Sediment can

also settle inside the drop pipe each time the pump

stops, and block the flow. For water sources that contain

high amounts of sand, clay, or other solids, consider the

following suggestions.

To avoid pumping dirty water

1. Have your well purged, developed, or otherwise

improved by a water well contractor before install-

ing the pump.

2. Temporarily install a more powerful pump to draw

at a high flow rate until the water looks clean.

3. Set the pump as high as possible in the well. If the

pump can be placed higher than the perforations

in the well casing, it will probably avoid all but the

finest suspended silt.

4. After lowering the pump in a well, wait at least

15 minutes for sediment or debris to settle down.

5. If the water source is at the surface, dig a shallow

well next to the water source to obtain clean

water.

6. If the water source is at the surface, use a fabric

screen to protect the pump. See section 5.5

If dirty water cannot be avoided

1. Use a reduced size of drop pipe. This will maximize

the velocity of water flow in order to exhaust sand

particles. Refer to section 12.3, Water Pipe Sizing

Chart. Select the smallest size pipe that does

not impose excessive friction loss. Use a reducer

bushing on the pump if necessary, to adapt it to

a smaller pipe size. See the caution about plastic

bushings in section 5.3

2. Monitor the situation regularly by observing the

volume of water pumped and/or the current draw

of the pump. For AC amps, see sections 8.3 and

12.8. As a pump wears, its flow rate (and current

draw) will decrease gradually. Replace the pump

end when reduced performance is observed, or

before your season of greatest water demand.

Increased current draw may indicate debris stuck

in the pump and/or pipe.

Before opening a pump that is clogged with dirt, see the

CAUTION about removing check valve, see section 8.1

QUESTION What effect

does hard, mineralized,

alkaline or salty water have?

— ANSWER Generally, none. Dissolved

minerals and salts are not abrasive.

QUESTION How is a pump

damaged from “dry run”? —

ANSWER If the pump runs

completely dry, parts will overheat and be

damaged. However, if water is only trickling

into the pump, it will usually provide enough

lubrication and cooling to prevent damage.

5.8 Utilizing a Low-Production Water Source

PS pumps can make the best of a limited water source,

even if the pumping rate can exceed the recovery rate.

You want to draw the most water possible, without run-

ning dry. PS-Pumps can handle this in two ways.

The low-water probe The low-water probe allows

the pump to work to its full potential until the water

level drops, see section 4.10. This is a good strategy

because you get all the water you can while the sun

shines. Place the pump near the bottom of the well to

utilize the storage of water in the well. When the pump

is stopped by the low-water probe, it re-starts after a 20

minute delay. The Low Water OFF light will slowly flash

even after the water recovers and the pump restarts,

to indicate that the level got low at some time during

the day. See section 4.10, Low Water Probe. It may be

feasible to hang the probe independently and use it to

locate the water level at any moment. See section 5.4,

Safety Rope and Binding

Reduce the Maximum RPM setting If the well has

little storage capacity, the supply may recover before the

20-minute restart delay. In this case, reduce the “Maxi-

mum RPM” setting in the controller. See section 4.6

WARNING Do not use a valve as a

means of reducing the flow. With a

helical rotor pump, excessive

pressure may result. Use the

Maximum RPM setting instead.

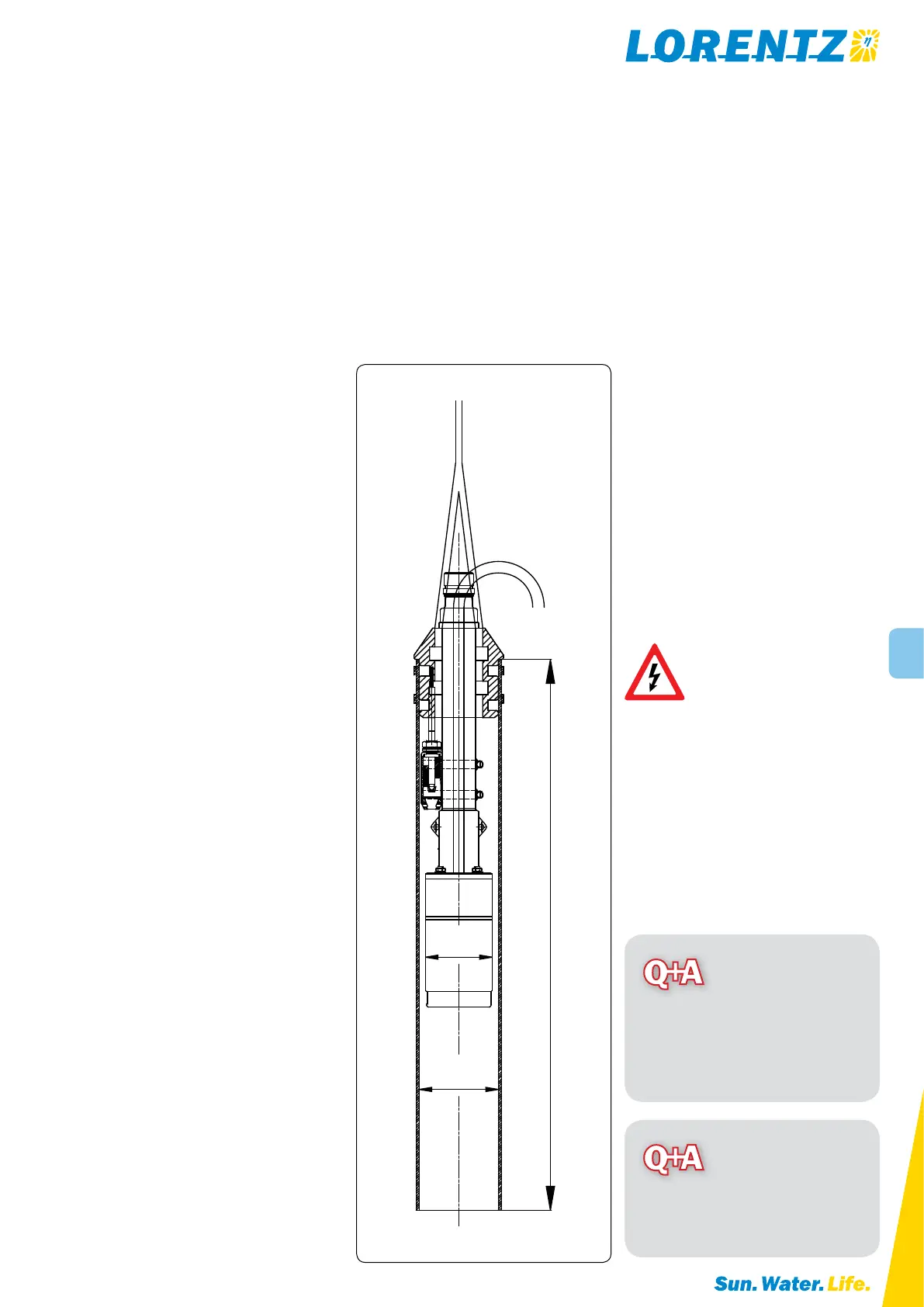

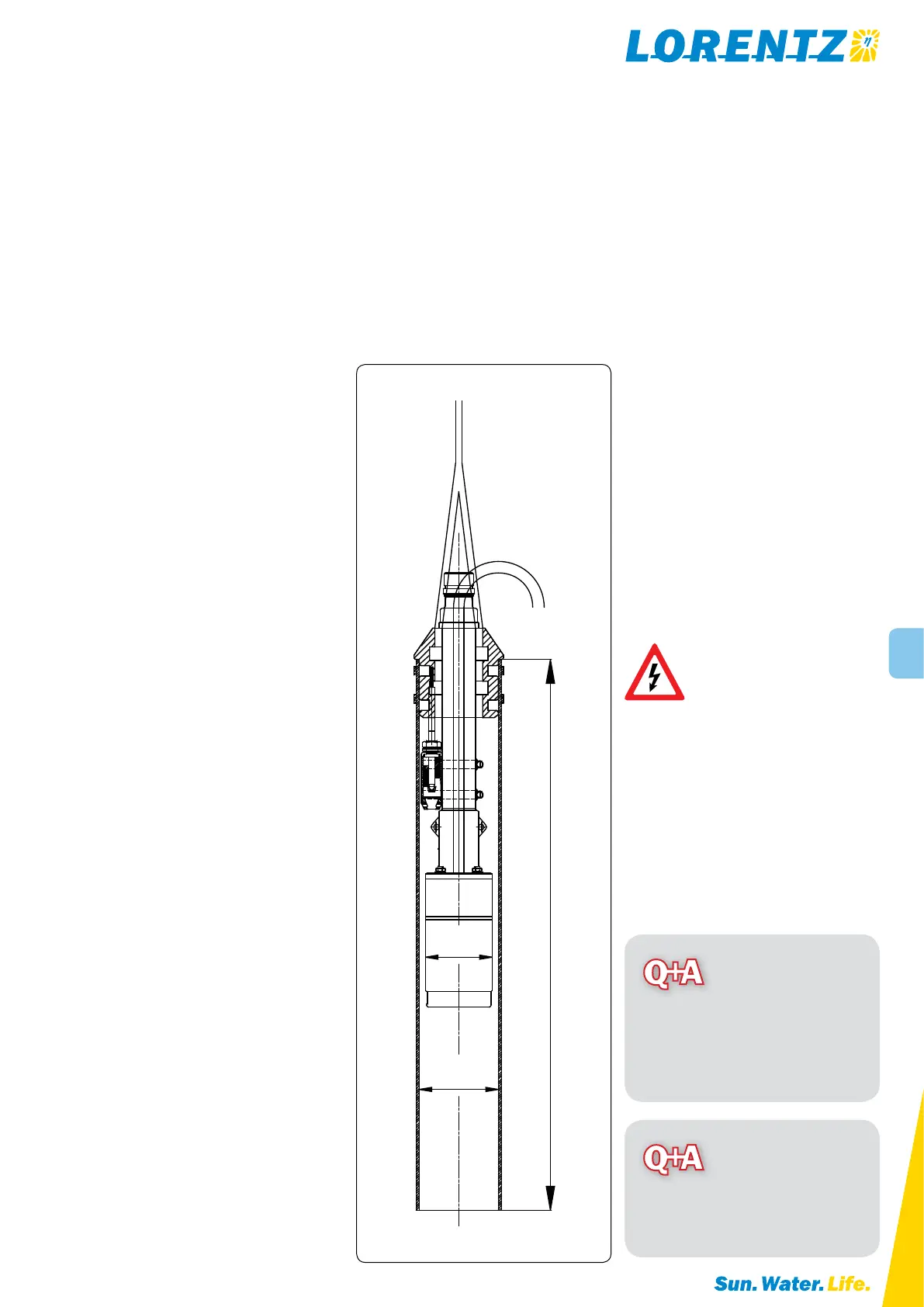

Add a stilling tube if operation in dirty water

conditions cannot be avoided Use a stilling tube

to protect the pump from dirt. This design prevents dirt

to enter from top or from the sides of the borehole into

pump. The large inner diametre of about 115 mm allows

the water to rise only very slowly, so that sand or other

heavy particles cannot be sucked into the pump.

Figure 23: Stilling tube for HR pumps

Loading...

Loading...