20

v130207

BERNT LORENTZ GmbH & Co. KG Kroegerskoppel 7, 24558 Henstedt-Ulzburg, Germany, Tel. +49 (0) 4193 7548 - 0, Fax - 29, www.lorentz.de

Errors excepted and possible alterations without prior notice.

4.13 Pressurizing Systems

LORENTZ PS pump systems are excellent for

automatic water pressurizing when powered by

a battery system. If you are raising water vertically

AND pressurizing, the pump must handle to total head.

Note the relationship: 2.31 ft = 1 PSI (1 bar = 10 m verti-

cal) Example: A pump that lifts 100 ft (30m) vertical and

pressurizes to 60 PSI (4 bar) must pump the equivalent

of 240 ft (70 m). Be sure your pump was chosen correctly

for your application. The installation is similar to that of

a conventional AC pump.

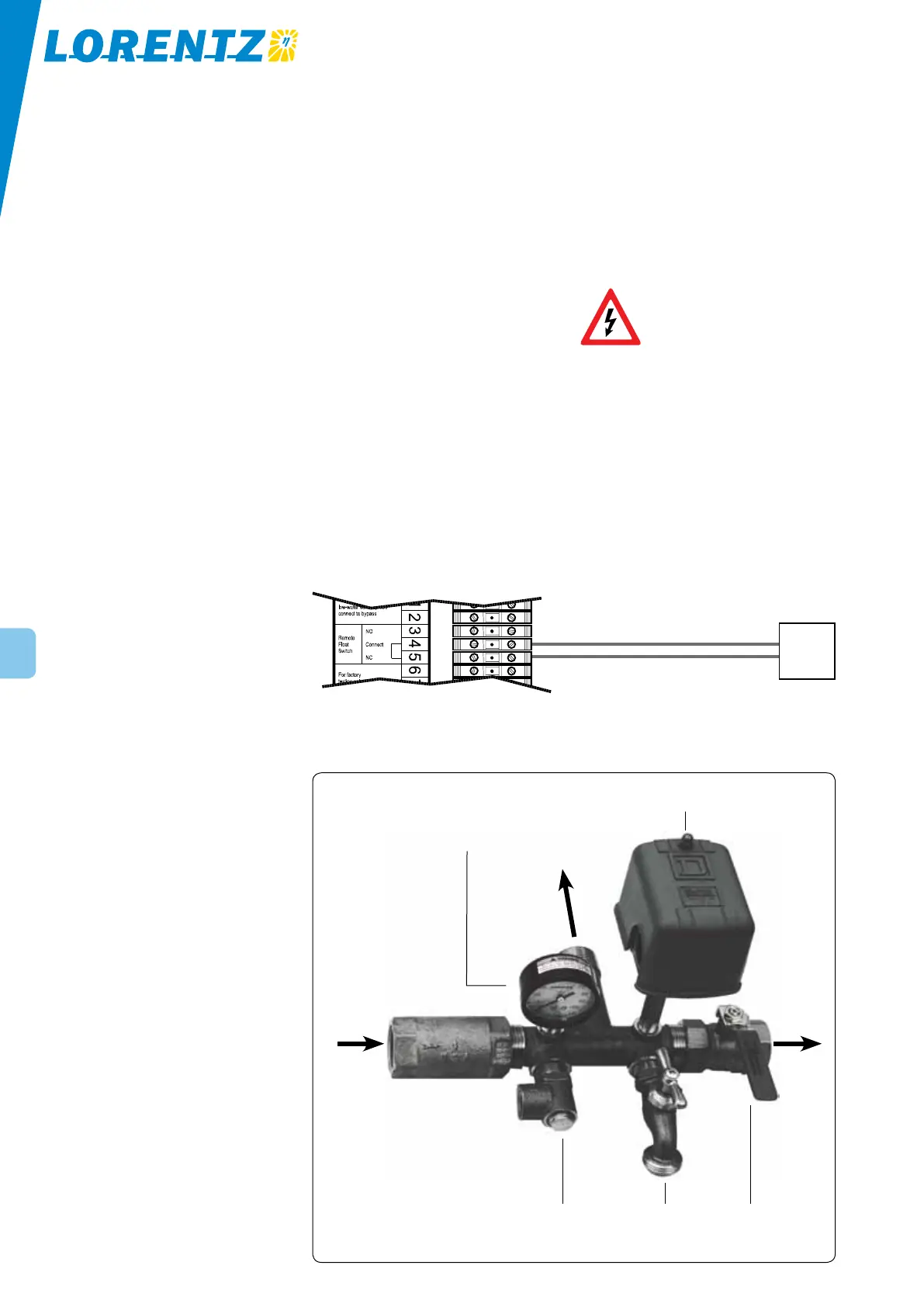

A typical pressurizing control assembly is il-

lustrated in the following photo. These are standard

components, same as used for conventional AC water

pressure systems. The parts (from left to right) are:

1. check valve (prevents back-flow)

2. pressure gauge 0-100 PSI (0-7 bar)

3. pressure relief valve 75

PSI (5.3 bar)

4. tank tee (a bronze casting that holds all the

components)

5. pressure switch (turns the pump on/off according

to pressure set-points, adjustable)

6. hose outlet (to drain the system or to supply water

when outlet is shut off)

7. ball valve (to shut off the supply to the outlets)

The components can be purchased from local suppliers,

or as a kit from your pump supplier.

Pressure tank A pressure tank is required. We recom-

mend a captive-air pressure tank of 40 US Gal. (150 l)

OR MORE, to assure a steady supply of water pressure

as the pump cycles on and off and the water demand

varies. A large tank is always best. Size and cost are the

only practical limitations. More than one tank can be

used to increase the total capacity.

How to pre-charge a captive-air pressure tank

for PS pump systems For the system to function

properly, the air bladder in the tank must be pre-charged

with air according to these instructions.

1. Make note of the cut-in setting of the pressure

switch (either by observation or knowing the

factory setting).

2. Turn off the pump and exhaust the water from the

tank if necessary, so the water pressure is 0.

3. Find the air fitting on top of the tank. Measure the

air pressure in the tank using a tire gauge.

4. Adjust the pressure to about 3 PSI (0.2 bar) LESS

THAN THE CUT-IN PRESSURE.

Pressure switch PS pumps systems can use an ordinary

pressure switch sold for conventional AC pumps. Do not

use a pressure switch with “low water cutout” or “loss

of prime” feature (with a shutoff lever on the side). It is

intended to prevent dry run of centrifugal pumps. The

helical rotor pump types will maintain pressure even

as it runs dry, so this device will not work reliably. It

will also shutoff if the pressure falls due to high water

demand.

Pressure switch connection There are two ways to

connect the pressure switch:

1. primary power switching The switch is used to

disconnect the DC power source. Wire the switch

between the power source distribution point and

the controller, as you would with a conventional

pump.

2. remote switching This method uses the

“remote float switch” terminals. Small wire (mini-

mum #18 AWG / 1 mm

2

) can be run to the pres-

sure switch from a long distance. See illustration

below. Advantage: the controller stays on all the

time. If the water source runs low (even if it recov-

ers) the “Source Low” indicator light will stay on

to notify the user. Power draw of the controller in

OFF mode is only about 1 watt.

WARNING A PRESSURE RELIEF

VALVE IS REQUIRED. If the pressure

switch fails, this will prevent

extreme pressure from bursting

the tank or piping and causing a flood. Install

the valve near the pressure tank, before the

shutoff valve. Use a 1/2 in (or larger) valve set

about 25 – 75 % higher than the cut-out pressure.

Run a pipe or hose from its outlet to a drain or

to the outdoors where water discharge will not

cause damage.

Figure 17: Wiring for pressure switch

pressure switch

pressure gauge to pressure

tank

WATER IN

from pump

WATER OUT

to distribution

system

check valve hose outlet tank tee

Figure 18: Typical assembly for automatic water pressurising

Loading...

Loading...