Doc: MHIT101A1012.doc 01/08/2013 p. 1 / 38

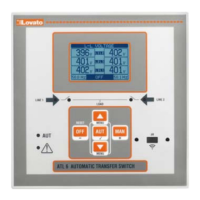

RGK600 RGK600

RGK600SA RGK600SA

Unità di controllo Generating set

per gruppi elettrogeni controller

MANUALE OPERATIVO INSTRUCTIONS MANUAL

Prima di qualsiasi intervento sullo strumento, togliere tensione dagli ingressi di misura e di

alimentazione e cortocircuitare i trasformatori di corrente.

Il costruttore non si assume responsabilità in merito alla sicurezza elettrica in caso di utilizzo

improprio del dispositivo.

I prodotti descritti in questo documento sono suscettibili in qualsiasi momento di evoluzioni o

di modifiche. Le descrizioni ed i dati a catalogo non possono pertanto avere alcun valore

contrattuale.

Un interruttore o disgiuntore va compreso nell’impianto elettrico dell’edificio. Esso deve

trovarsi in stretta vicinanza dell’apparecchio ed essere facilmente raggiungibile da parte

dell’operatore. Deve essere marchiato come il dispositivo di interruzione dell’apparecchio: IEC/

EN 61010-1 § 6.12.2.1.

Pulire lo strumento con panno morbido, non usare prodotti abrasivi, detergenti liquidi o

solventi.

Before any maintenance operation on the device, remove all the voltages from measuring

and supply inputs and short-circuit the CT input terminals.

Products illustrated herein are subject to alteration and changes without prior notice.

Technical data and descriptions in the documentation are accurate, to the best of our

knowledge, but no liabilities for errors, omissions or contingencies arising there from are

accepted.

A circuit breaker must be included in the electrical installation of the building. It must be

installed close by the equipment and within easy reach of the operator.

It must be marked as the disconnecting device of the equipment:

IEC /EN 61010-1 § 6.12.2.1.

Clean the instrument with a soft dry cloth; do not use abrasives, liquid detergents or

solvents

.

Indice Pagina

Introduzione 2

Descrizione 2

Funzione dei tasti frontali 3

LED frontali 3

Modi operativi 3

Messa in tensione 3

Menu principale 4

ccesso tramite password 4

Tabella delle pagine del display 5

Sensori resistivi carburante, temperatura, pressione

7

Start remoto su vesrioni ..SA

8

Ingressi, uscite, variabili interne, contatori 8

Soglie limite (LIMx) 8

Variabili da remoto (REMx) 9

llarmi utente (UAx) 9

Test automatico 10

Modo sleep 10

CAN bus 10

Porta di programmazione IR 12

Impostazione parametri da PC 12

Impostazione parametri da pannello frontale 13

Tabella dei parametri 14

llarmi 25

Proprietà degli allarmi 25

Tabella allarmi 26

Descrizione degli allarmi 28

Tabella funzioni ingressi 30

Tabella funzioni uscite 31

Menu comandi 32

Installazione 33

Schemi di connessione 34

Disposizione morsetti 36

Dimensioni meccaniche e foratura pannello 36

Caratteristiche tecniche 37

Cronologia revisioni manuale 38

Index Page

Introduction 2

Description 2

Front buttons functions 3

Front LED indication 3

Operating modes 3

Power-up 3

Main menu 4

Password access 4

Table of display pages 5

Resistive sensors for fuel, temperature and pressure

7

Remote start for …SA versions

8

Inputs, outputs, internal variables, counters 8

Limit thresholds (LIMx) 8

Remote-controlled variables (REMx) 9

User alarms (UAx) 9

utomatic test 10

Sleep mode 10

CAN bus 10

IR programming port 12

Parameter setting via PC 12

Parameters setting (setup) from front panel 13

Parameter table 14

larms 25

larm properties 25

larm table 26

larm description 28

Input function table 30

Output function table 31

Command menu 32

Installation 33

Wiring diagrams 34

Terminal position 36

Mechanical dimensions and panel cutout 36

Technical characteristics 37

Manual revision history 38

ATTENZIONE!!

Leggere attentamente il manuale prima dell’utilizzo e l’installazione.

Questi apparecchi devono essere installati da personale qualificato, nel

rispetto delle vigenti normative impiantistiche, allo scopo di evitare danni a

persone o cose.

WARNING!

x Carefully read the manual before the installation or use.

x This equipment is to be installed by qualified personnel, complying to

current standards, to avoid damages or safety hazards.

Loading...

Loading...