How to fix external hydraulic fluid leakage in LS LL2300 Farm Equipment?

- PPatricia ShortAug 18, 2025

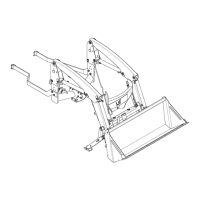

To address external hydraulic fluid leakage in your LS Farm Equipment, start by checking for loose hydraulic connections and tighten them. If the leak persists, inspect hydraulic hoses, tube lines, adapter fittings, and O-rings for defects and replace any damaged parts. Also, examine the control valve O-rings and replace them if they are defective. If the control valve spool or body is damaged or worn, consider replacing the entire control valve. Finally, check the cylinder rod packing set for leakage and repair as needed.