Form # 46620 Issue 11/06

50

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

Wobble Box Maintenance

NOTE: For double sickle headers, perform

maintenance at both boxes.

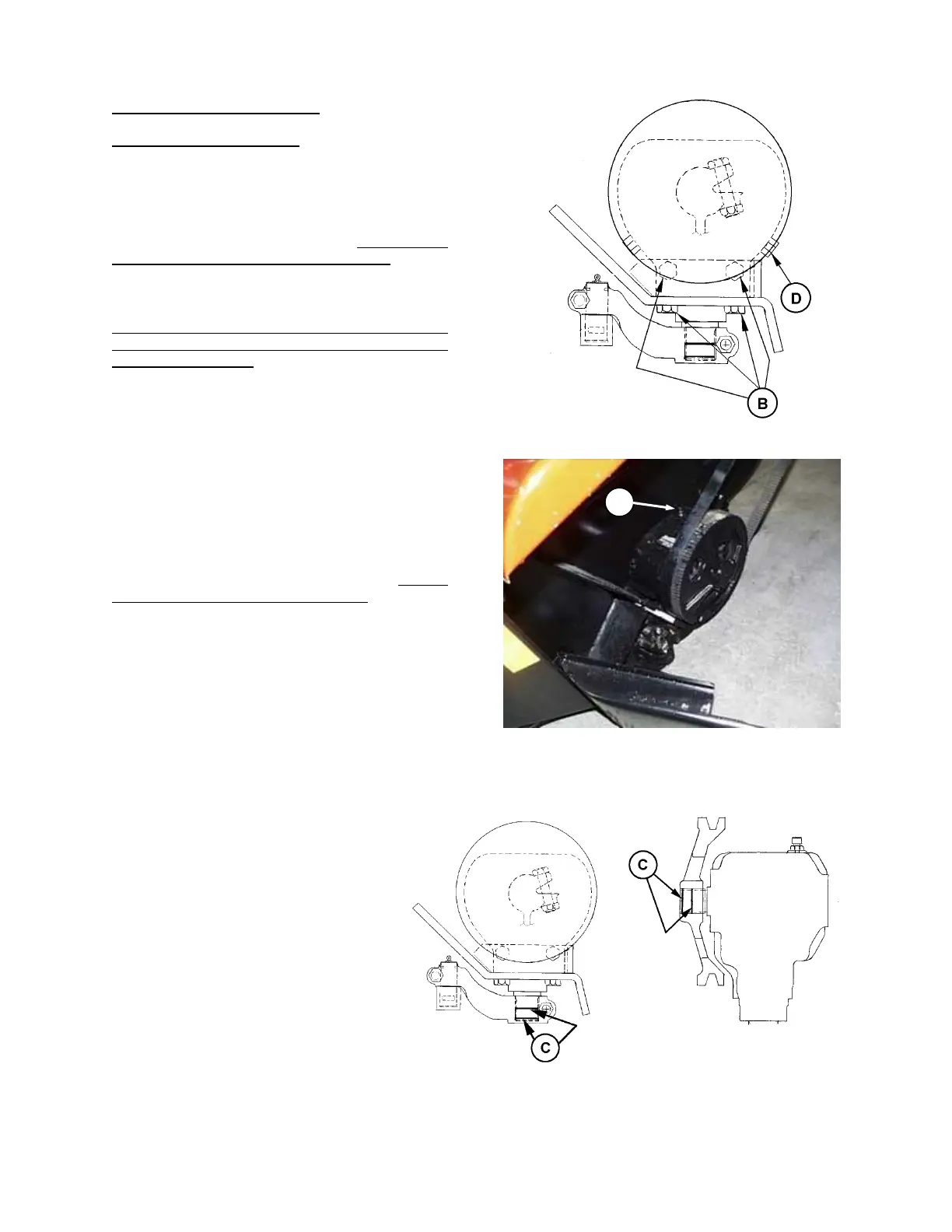

Mounting Bolts - Check four wobble box

mounting bolts (B) torque after the first 10 hours

operation and every 100 hours thereafter. Torque

should be 200 ft.lbs. (270 N⋅m). When tightening,

start with the side mounting bolts.

Lubricant - Check wobble box lubricant level

before first operation and every 100 hours

thereafter. To check:

1. Raise header to a point where the wobble box

base is approximately level.

2. Remove breather/dipstick (A). Oil level must be

between end of dipstick and bottom hole (or

groove) in dipstick.

3. Add as required. See "Recommended Lubri-

cants" for specified gear lube and capacity of

box.

4. Replace breather/dipstick.

Change wobble box lubricant after the first 50

hours operation and every 1000 hours (or 3 years)

thereafter.

To drain wobble box, raise header fully and

engage header lift cylinder stops. Remove drain

plug from box at (D).

Assembly/Disassembly

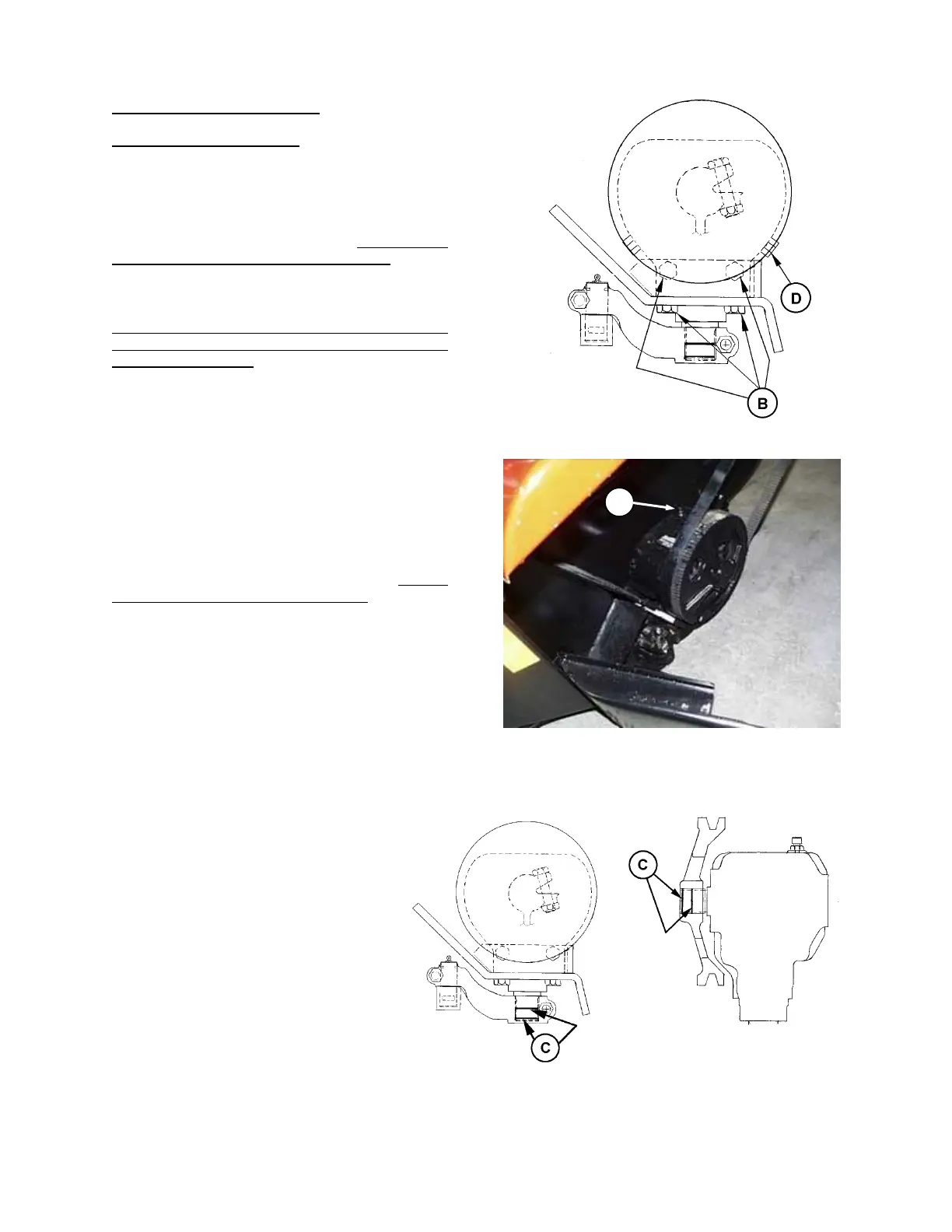

When reinstalling drive arm or pulley:

1. Remove any rust or paint from

inner spline. For replacement parts,

remove oil/grease with degreasing

agent.

2. Before assembly, apply Loctite®

#243 adhesive (or equivalent) to

spline. Apply in two bands (C) as

shown, with one band at end of

spline and one band approximately

mid-way.

W

BBLE B

X M

NTIN

B

LT

DRAIN PL

USE ADHESIVE FOR ASSEMBLY

WOBBLE BOX LUBRICANT

A

Loading...

Loading...