Form # 46584 Issue 11/06 Web Rev_01

106

MAINTENANCE/SERVICE

Traction Drive: Wheels and Tires (continued)

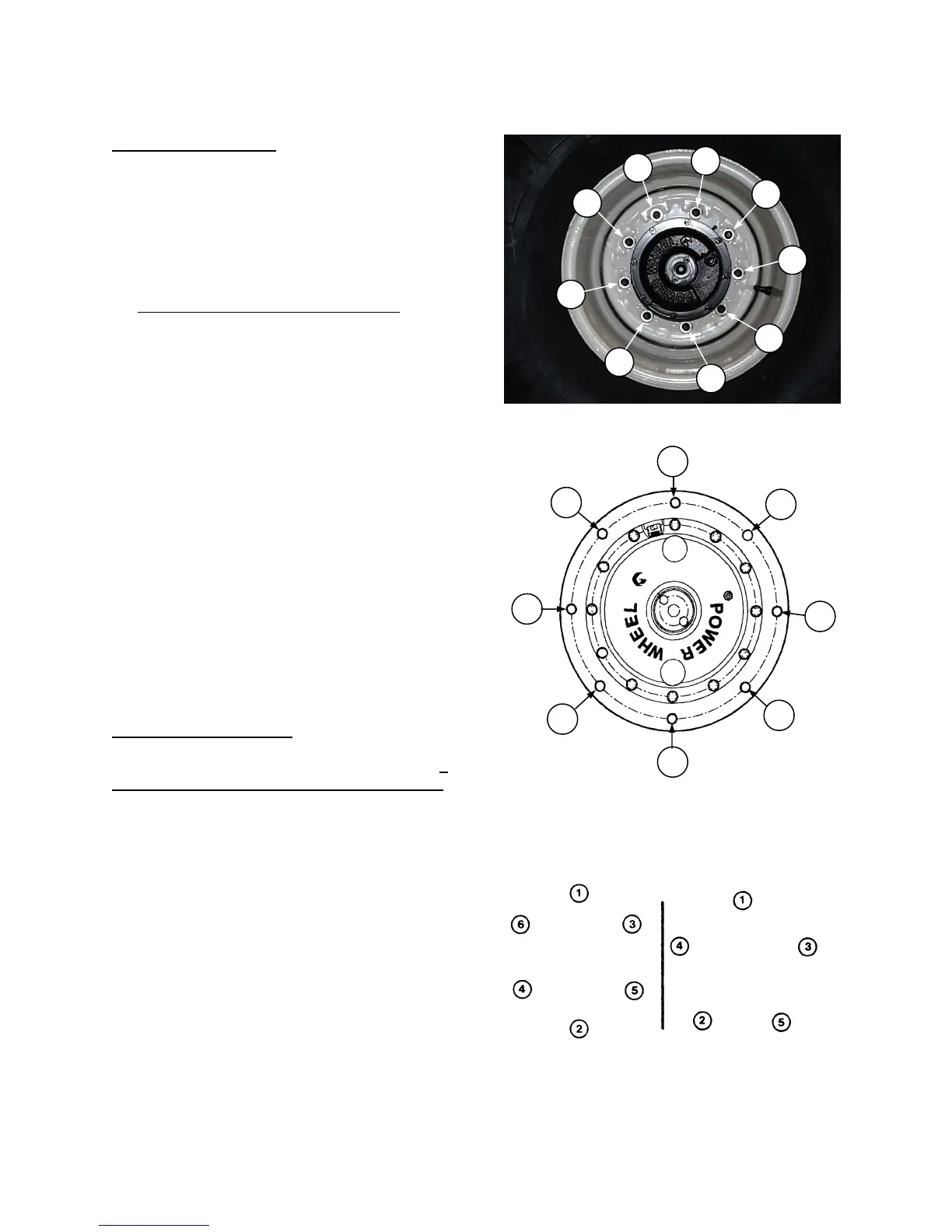

DRIVE WHEEL BOLTS

At first use, or when a wheel is removed, check

drive wheel bolt torque according to the following

schedule:

• Every 15 minutes on the road or 60 minutes in

the field until torque stabilizes, then

• Daily (10 hours) until no change is recorded for

3 consecutive days (30 hours), then

• Every 200 hours or annually thereafter

.

Torque Specification for drive wheels:

9 Bolt Rim: 130 ft.lbs. (175 N⋅m). Torque in

numbered sequence shown at right. Repeat

sequence three times.

8 Bolt Rim: 180 ft.lbs. (245 N·m). Torque in

numbered sequence shown at right. Repeat

sequence three times.

NOTE: When installing drive tires, be sure air

valves are on the outside and tire tread points

forward.

For "Turf and Field" tires (diamond or rectangular

tread), be sure arrow on sidewall points in forward

rotation.

CASTER WHEEL BOLTS

Check caster wheel bolt torque after the first 5

hours and every 200 hours or annually thereafter.

Torque specification for caster wheels:

9.5L-14: 50 to 60 ft.lbs. (70 to 80 N⋅m)

16.5L-16.1, 11-16 or 7.5-16: 100 ft.lbs. (135 N⋅m)

Whenever a wheel is removed and re-installed,

check torque after one hour of operation.

IMPORTANT: To prevent damage to wheel disc,

do not over-tighten wheel nuts.

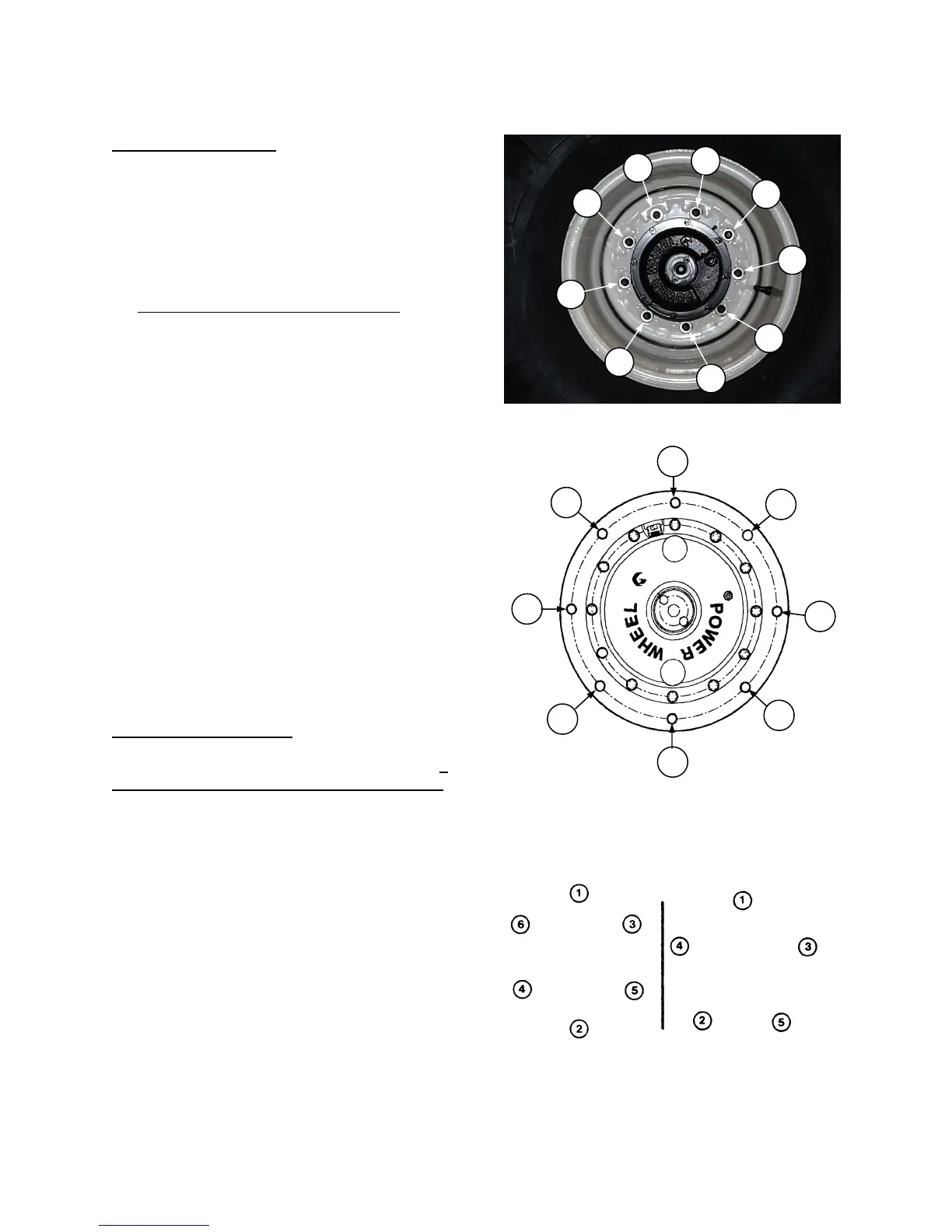

Follow the proper bolt tightening sequence shown

at right.

1

4

7

8

2

5

9

3

6

9-BOLT WHEEL

TIGHTENING SEQUENCE

8-BOLT WHEEL

TIGHTENING

1

7

8

6

5

4

3

2

6-BOLT WHEEL 5-BOLT WHEEL

TIGHTENING SEQUENCE

Loading...

Loading...