UNLOADING AND ASSEMBLY

Form 169078 Revision C

LUBRICATE THE HEADER (Cont’d)

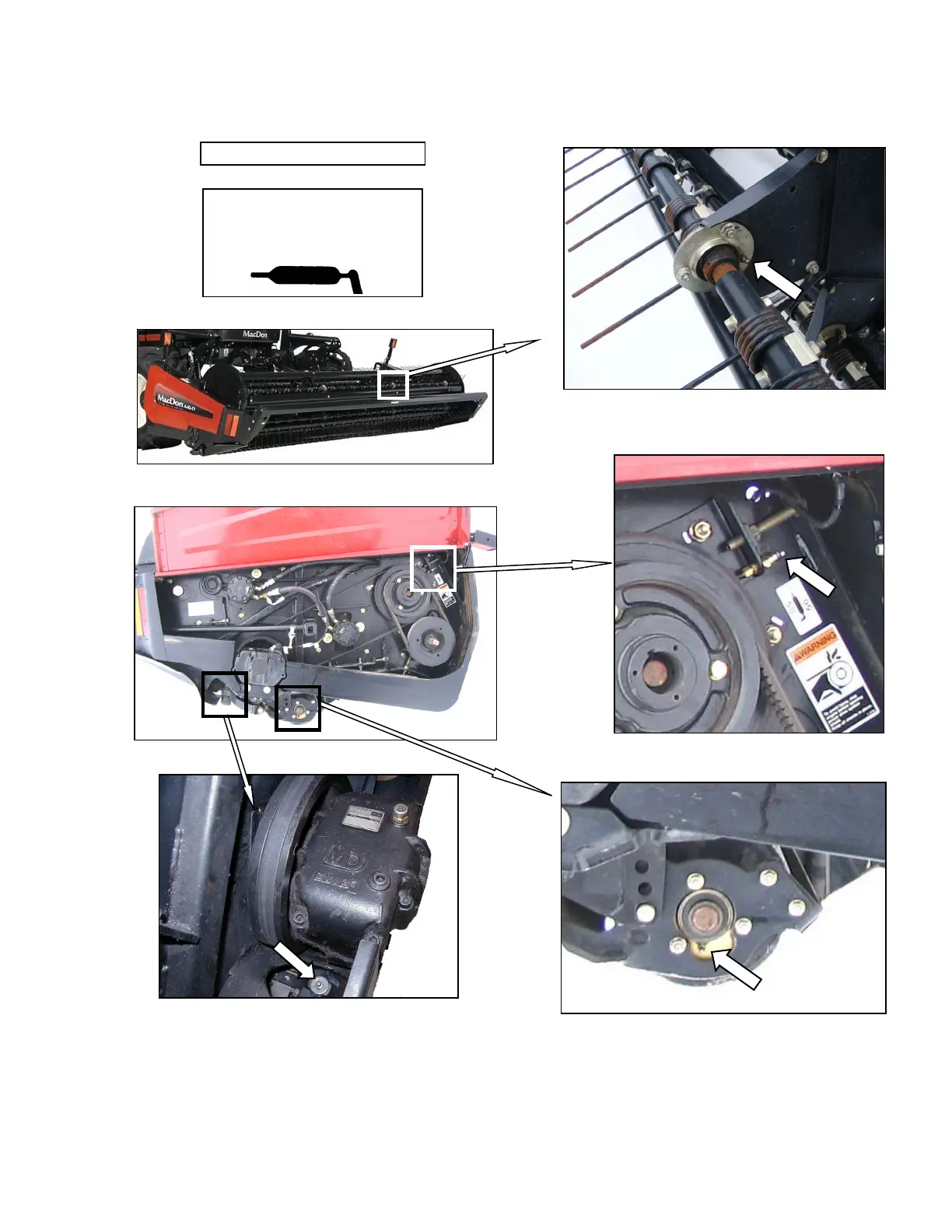

To prevent binding and/or excessive

wear caused by sickle pressing on

guards, do not over grease. If more

than 6 to 8 pumps of the grease gun

are required to fill the cavity, replace

the seal in the sickle head.

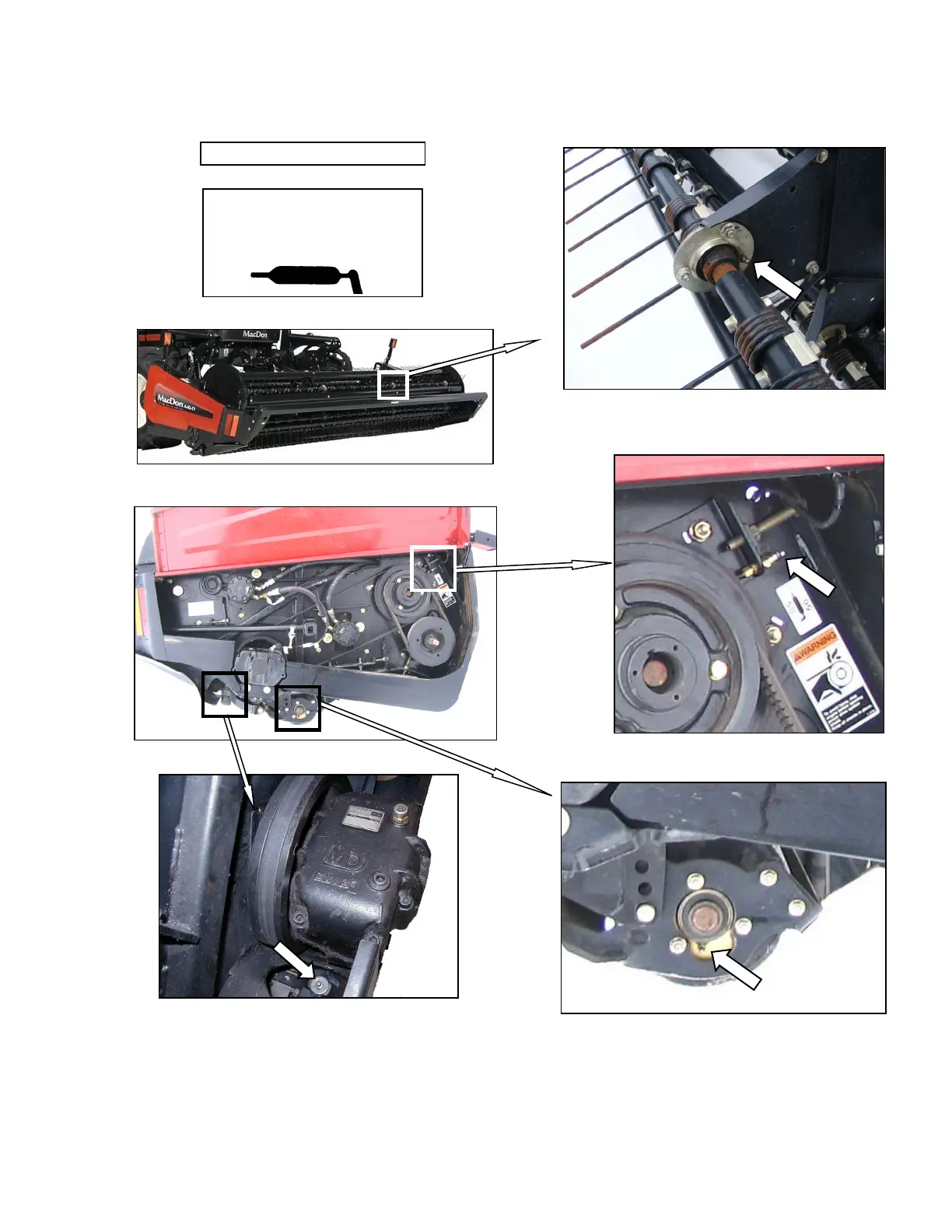

SICKLE HEAD BEARING (1 PLC)

SICKLE DRIVE BEARING (1 PLC)

GAUGE ROLLER BEARINGS (2 PLCS)

BOTH SIDES - IF INSTALLED

Pressure (EP2) Performance With

1% Max Molybdenum Disulphide

(NLGI Grade 2) Lithium Base

TINE BAR BEARING

(4 PLCS EACH TINE BAR)

Loading...

Loading...