MAINTENANCE AND SERVICING

5.11 Maintena

nce Schedule

The Maintenan

ce Schedule (see next page) species the periodic maintenance procedures and service intervals.

Regular maint

enance is the best insurance against early wear and untimely breakdowns. Following this schedule

will increase

machine life.

For detailed

instructions, refer to the various procedures in this chapter. Use the uids and lubricants specied in

Section 5.1.

2 Recommended Fuel, Fluids, and Lubricants, page 212.

Service Int

ervals: The recommended service intervals are in hours of operation. Where a service interval is given

in more than

one time frame, for example, 100 hours or annually, service the machine at whichever interval is

reached rs

t.

IMPORTANT

Recommended intervals are for average conditions. Service the machine more often if operated under

adverse conditions (severe dust, extra heavy loads, etc.).

CAUTION

Carefully follow safety messages given under RECOMMENDED SAFETY PROCEDURES.

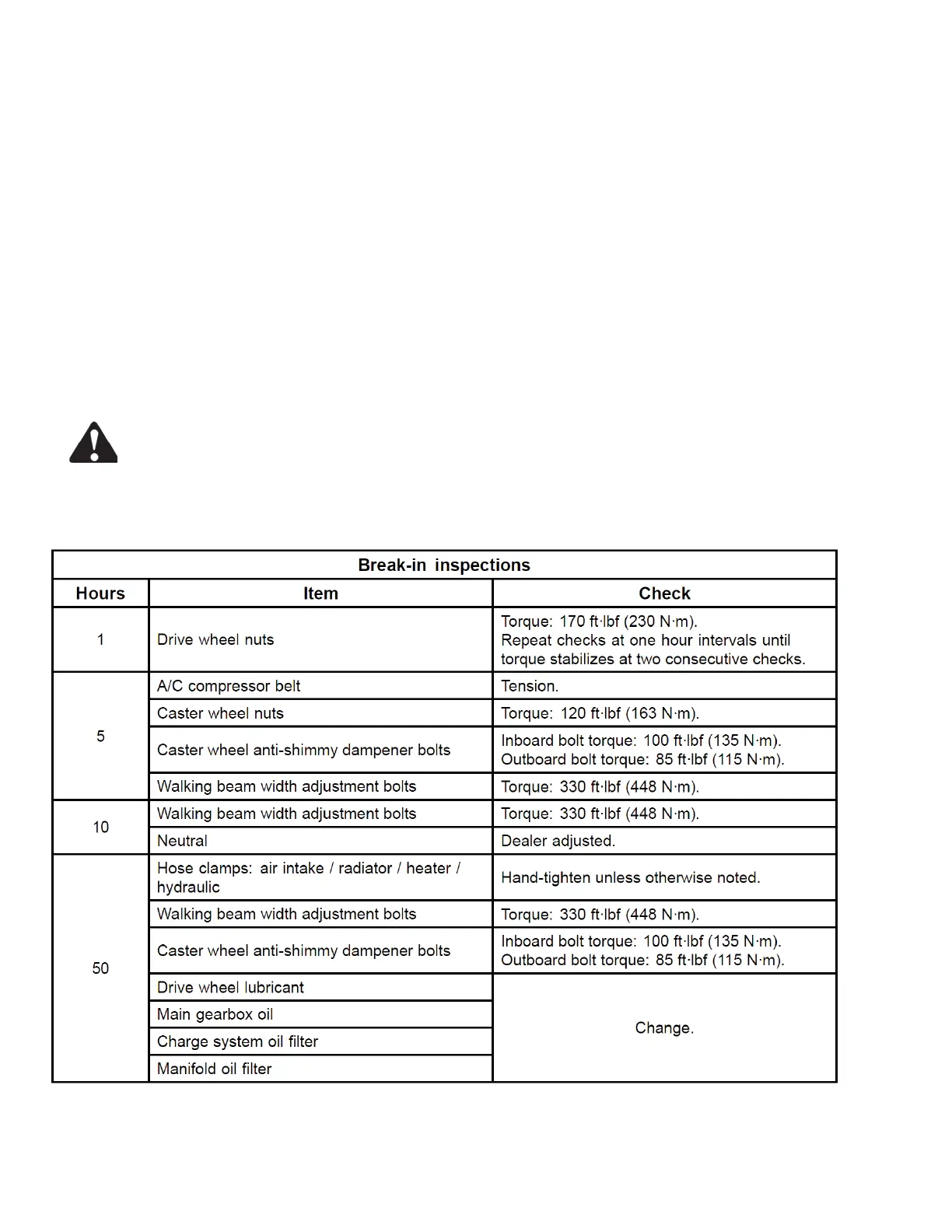

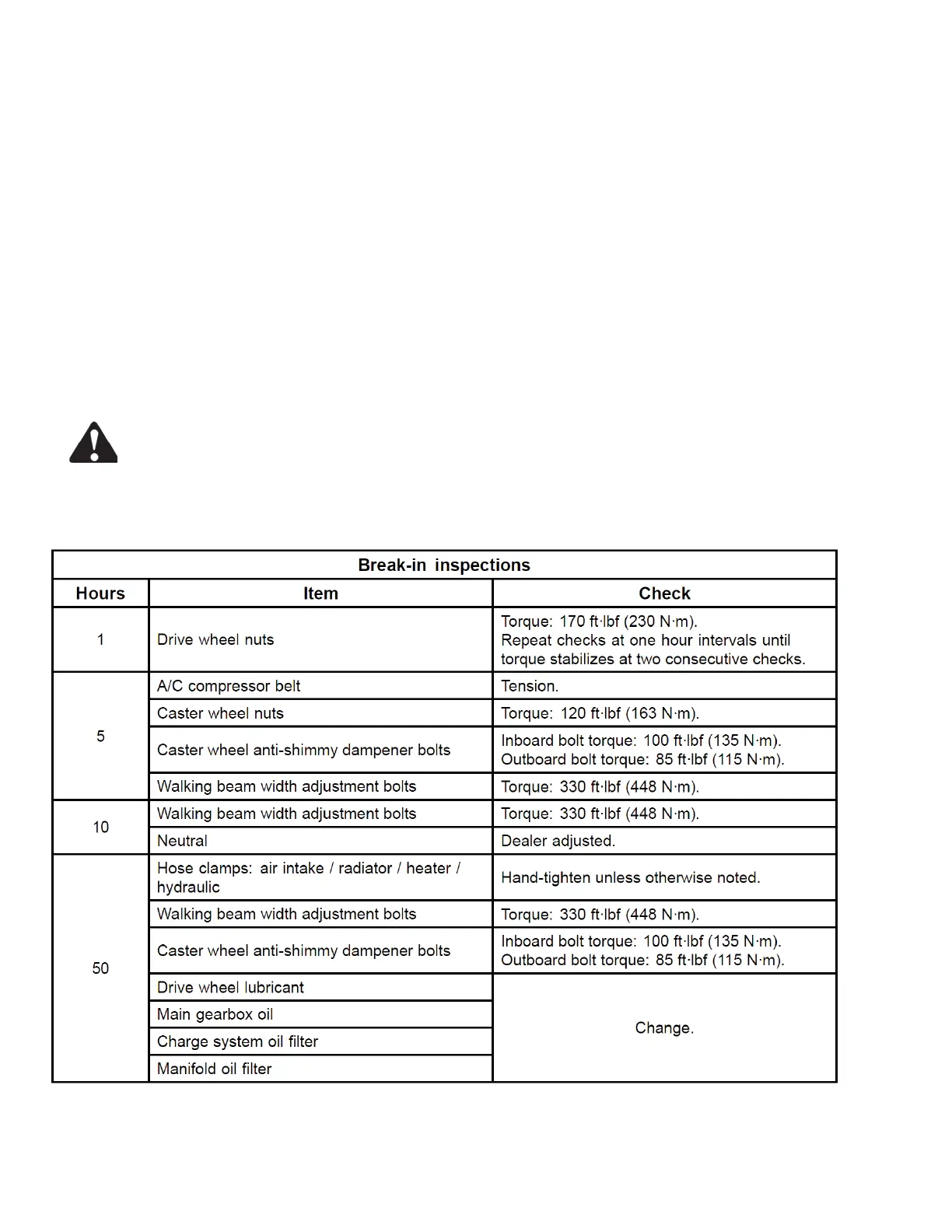

5.11.1 Break-In Inspections

Break-in inspections

Hours Item

Check

1 Drive wheel nuts

Torque: 220 ftlbf (300 Nm).

Repeat checks at one hour intervals until

torque stabilizes at two consecutive checks.

A/C compressor belt Tension.

Caster wheel nuts Torque: 120 ftlbf (163 Nm).

Caster wheel anti-shimmy dampener bolts

Inboard bolt torque: 100 ftlbf (135 Nm).

Outboard bolt torque: 85 ftlbf (115 Nm).

5

Walkin

g beam width adjustment bolts

Torque: 330 ftlbf (448 Nm).

Walking beam width adjustment bolts

Torque: 330 ftlbf (448 Nm).

10

Neutral Dealer adjusted.

Hose clamps: air intake / radiator / heater /

hydraulic

Hand-tighten unless otherwise noted.

Walking beam width adjustment bolts

Torque: 330 ftlbf (448 Nm).

Caster wheel anti-shimmy dampener bolts

Inboard bolt torque: 100 ftlbf (135 Nm).

Outboard bolt torque: 85 ftlbf (115 Nm).

Drive wheel lubricant

Main gearbox oil

Charge system oil lter

50

Return oil lter (if applicable)

Ch

ange.

169469 3

34

Rev. F

Replaces Page 334 in M205 Op Manual

Loading...

Loading...