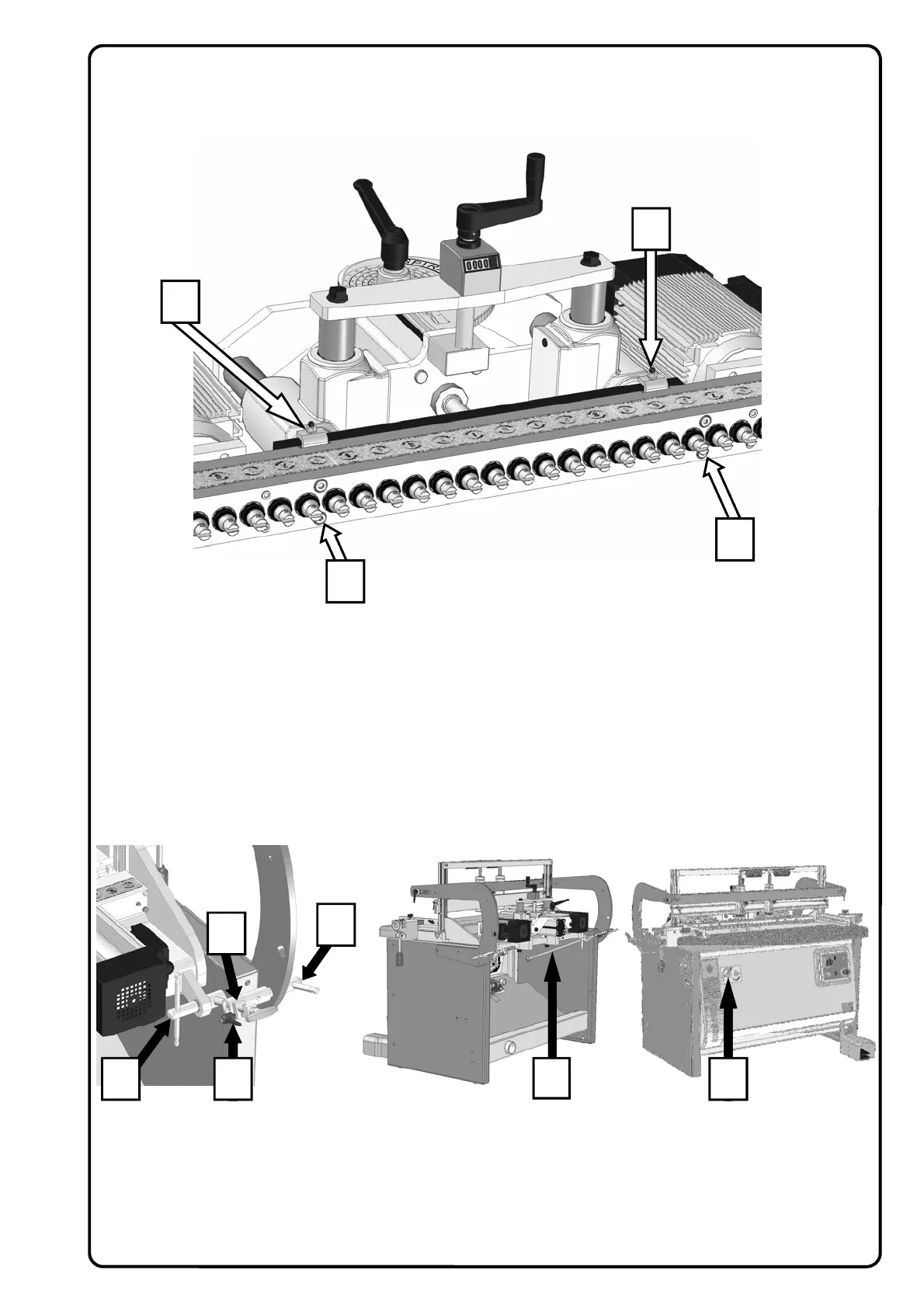

15.4 SPINDLE HEAD HORIZONTAL AND VERTICAL POSITIONING

POINT 1 “Caution danger” Carefully follow the whole procedure described below. To position the spindle head

at 90° ( POS. A ) starting from 0° as shown in the figure, proceed as follows:

− Release the handles (1 and 2)

− Use the control lever (3), positioned on the front side of the machine, and move it to the lower position.

− Lock the handles (1 and 2) again.

POINT 2 To position the spindle head at 0° starting from 90° ( POS. A ), proceed as follows:

− Check that the control lever (3), on the front side of the machine, is also positioned at 90° (lower position)

− Release the handles (1 and 2)

− Use the control lever (3) and move it to the upper position to overturn the head unit

− Lock the handles (1 and 2) again.

SPINDLE HEAD POSITIONING AT AN INTERMEDIATE ANGLE OF 45°

− Please position the head unit at 90°.

− Release the handles (1 and 2) to be able to pull out the graduated fence (4)

− Release the handle (5) and position the stop (6) at the required degrees from 0° to 90° along the gradu-

ated fence and then lock again.

− Follow the procedure described at Paragraph 15.4 Point 2 ( head positioning at 0° ) the unit will stop in

the chosen position

− Then lock the handles (1 and 2) again.

C

B

A

A

4 5

2

1 3

6

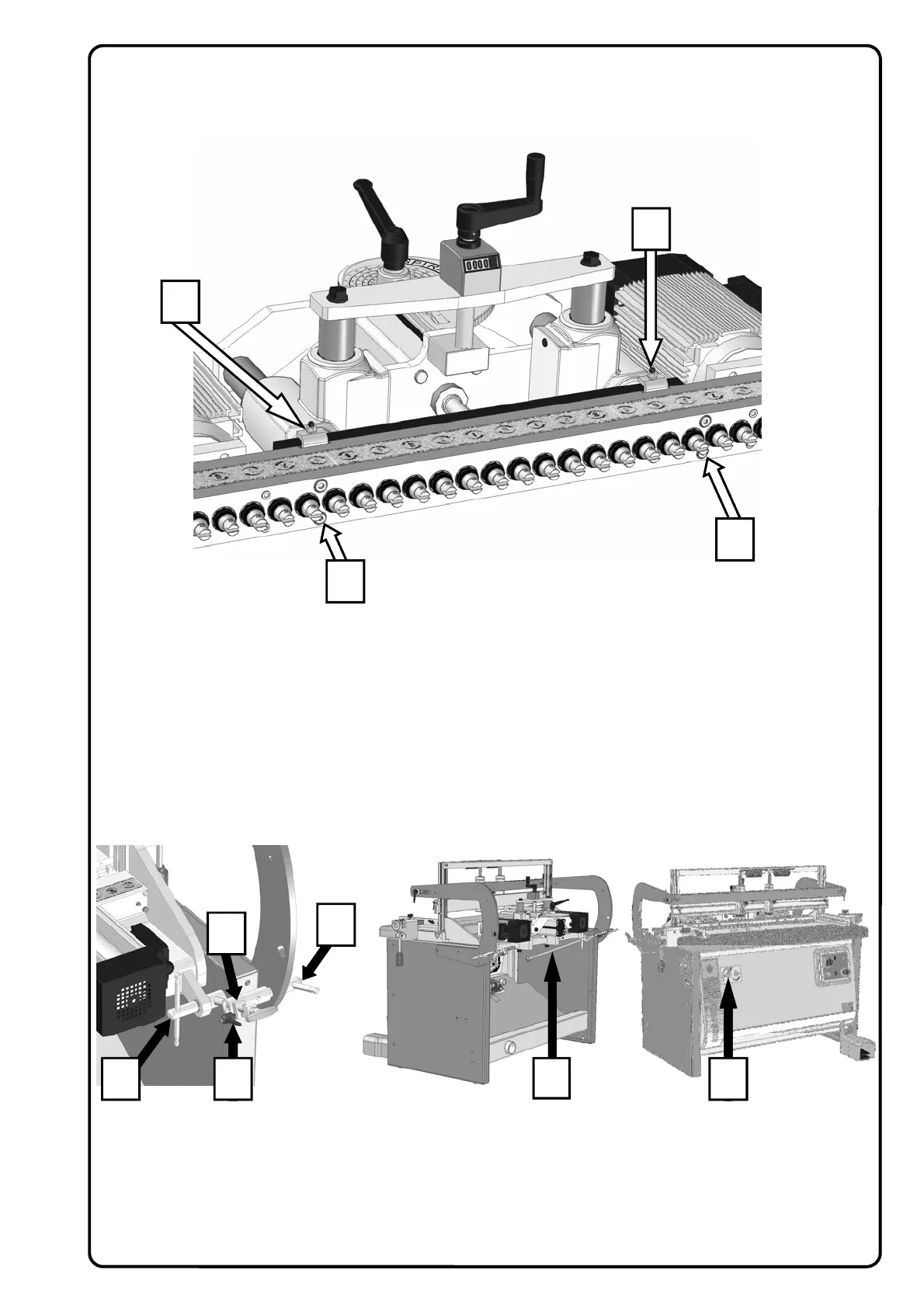

HEAD PARALLELISM ADJUSTMENT

− Partially loosen the screws ( A ) and work alternately on the screws ( B ) and nuts ( C )

− Set the drills parallel to the work table

− Firmly tighten the screws ( A )

Loading...

Loading...