15. CHECK UP AND ADJUSTMENTS

15.1 ELECTRICAL INSULATION PROCEDURE

Before starting with any maintenance operation on the machine please follow the following procedure:

1. verify that the machine is in the arranged position for the requested operation. Insulate electric and pneu-

matic system only after having blocked mechanically the machine in this position.

2. be sure that no any other power source is present, and that no residual power source is able to act.

It is extremely important that this procedure is performed by only one operator and he/she has to notify the ma-

chine state by putting on it a well visible tag.

15.2 PRELIMINARY CHECK UP

Check that the working area all around the machine is in order and without any residuals of machined material,

as sawdust or wood pieces.

Check that all the safety protection devices are positioned correctly and ready to use.

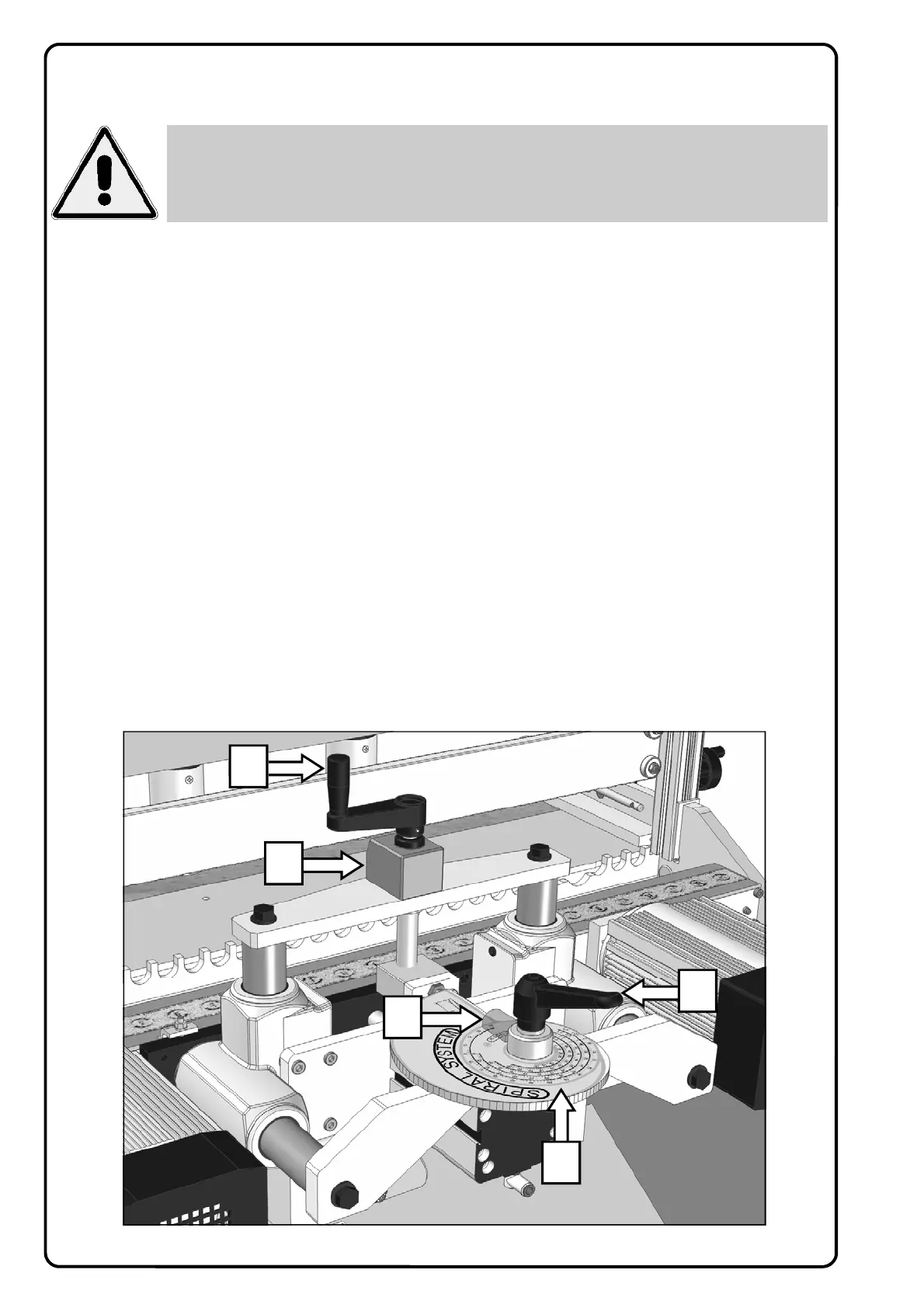

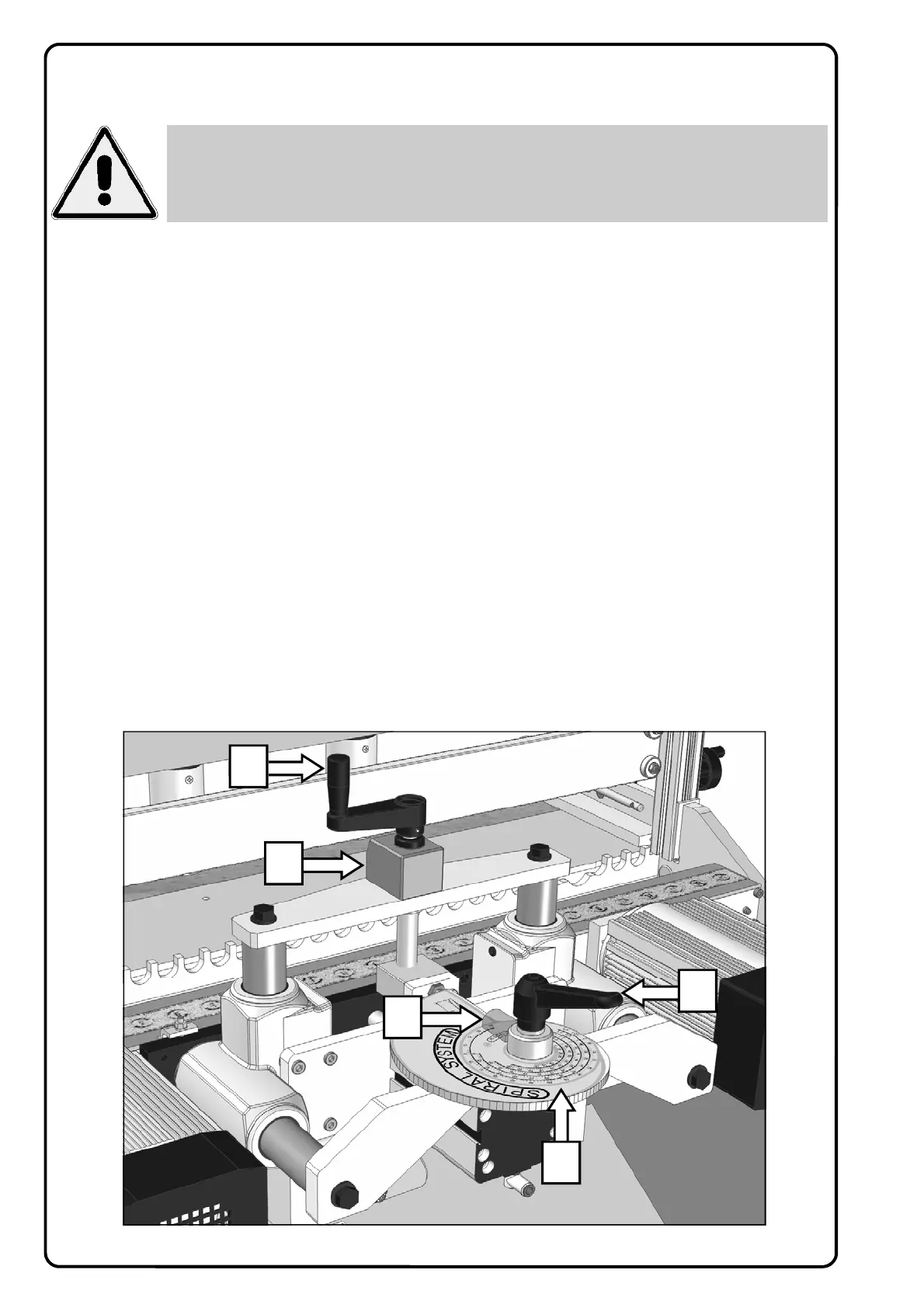

15.3 DRILLING DEPTH AND SPINDLE HEAD ADJUSTMENT

To carry out boring operations, proceed as described below:

1) Insert the suitable drills in the required position on the spindle head

2) Turn the handle (1) to set the required height of the drills from the work table, with the head turned at 0°.

The drill height is shown on the digital counter (2) in millimetres. Turn the handle so that the screw is

stretched when the required height is reached. The choice of the tool depends on the thickness of the piece to

be bored, the position of the hole and the hole diameter.

3) Proceed as follows to adjust the boring depth: once you have found on the depth selection screw (3) the

scale referring to the total length of the drill being used, it is possible to set (with no need for calculation) the

actual boring depth. Releasing the handle (4) and turning the depth selection screw to the required point, the

pointer (5) which also acts as a magnifier, will show the chosen depth. Firmly tighten the handle (4) before

starting boring operations.

4) Usually use a scrap piece of wood to test the machine settings before boring a good piece of wood.

IT IS RECOMMENDED TO DISCONNECT THE ELECTRICAL AND PNEUMATIC POWER

SUPPLY BEFORE TAKING ANY INTERVENTION ON THE MACHINE FOR MAINTENANCE

OR FOR REPLACING DAMAGED OR WORN PARTS. FOLLOW ALL THE PROCEDURES

DESCRIBED BELOW AND THE ADVICE WRITTEN IN CHAPTER 6 OF THIS MANUAL.

2

3

4

5

1

Loading...

Loading...