19. ANOMALIES DURING ORDINARY WORKING PHASES

19.1 BURN-TRACES DUE TO DRILLS

T

his problem might appear when the piece is positioned incorrectly or owing to drill wear or if the drills turn in

the opposite direction.

19.2 DRILLED PIECES ARE NOT PARALLEL TO THE REFERENCE BAR

This might be due to incorrect parallelism of the drills in relation to the reference stop. Check the heads in re-

lation to the stop and the parallelism of the line of drills of head 1 with head 2.

19.3 DIFFICOLTY IN TURNING THE HEAD

If the boring unit fails to reach or finds it difficult to reach other positions, check the hinge and rod of the over-

turning piston

19.4 THE WORKING PIECE IS NOT BLOCKED BY THE SAFETY CLAMP

If the clamps are not clamping properly, check the air pressure and connection pipes.

To solve these problems we suggest you contact Maggi Engineering Post-Sale Service, or your local dealer.

20. NOISE EMISSION

Noise emission according to correct working of machine and balancing and grinding of tools, is variable and

depends on working material, drill diameter and depth drill. The operator permanence expected time is vari-

able during 8 hours a day. Some other factors may determinate the exposure level; the surroundings and

other noise sources, and other close machines.

We suggest to inform the operators about risks caused by a prolonged exposure to noise, providing them with

suitable individual protection devices. The acoustic pressure level, collected in the operator place through

class 1 integrative noise meter, is 76.1 dB(A).

This measure was done according to ISO3745 rules with usual working values of speed and air pressure, drill-

ing a shaving wood PVC covered panel. The measure was executed at 1.5 m from ground, in front of the ma-

chine, in the operator position.

Moreover the following reference measures were collected with the same procedure:

Acoustic pressure level in Atm. dB(A): 78.3

Acoustic pressure power dB(A): 93.3

21. DUST EMISSION

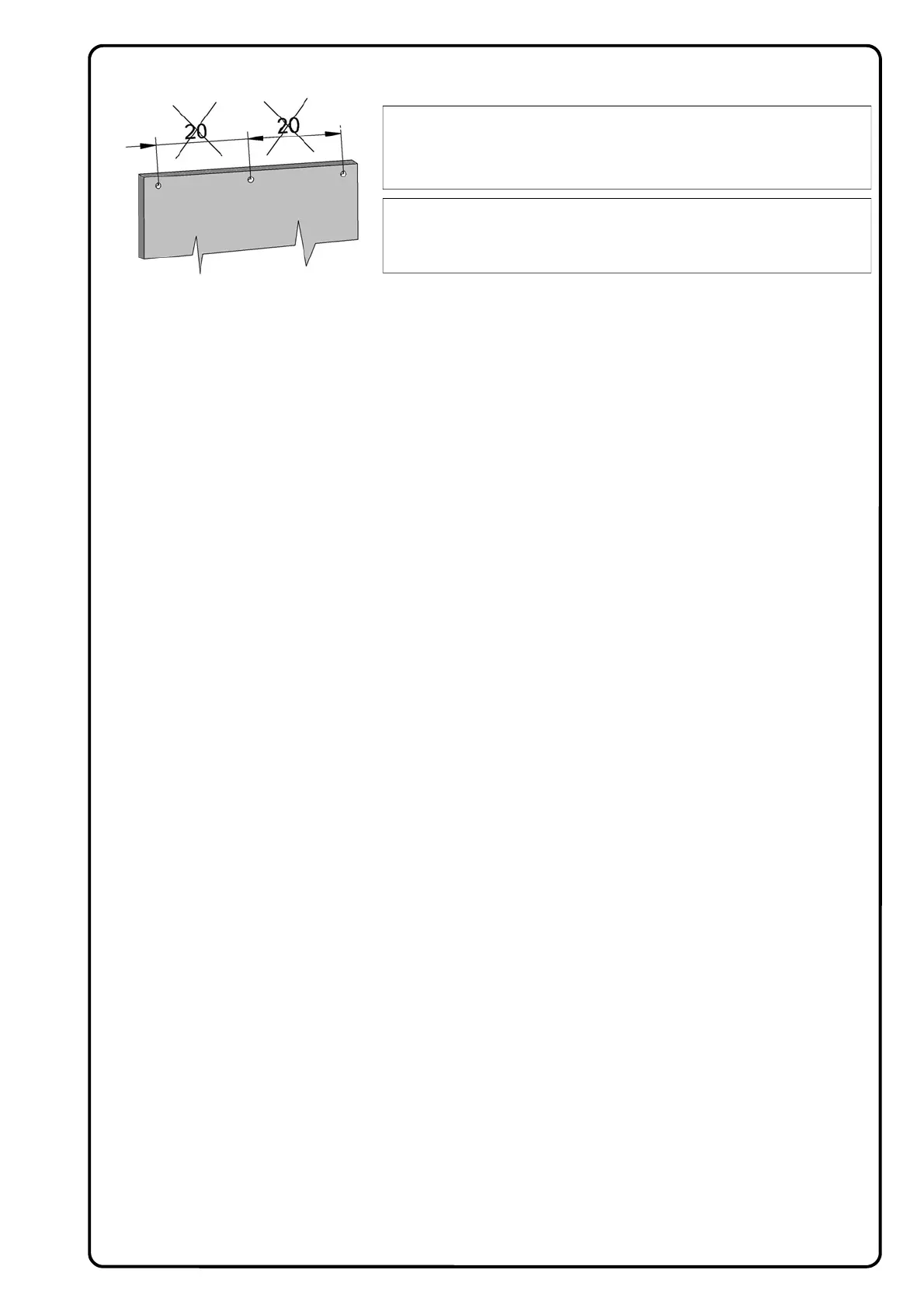

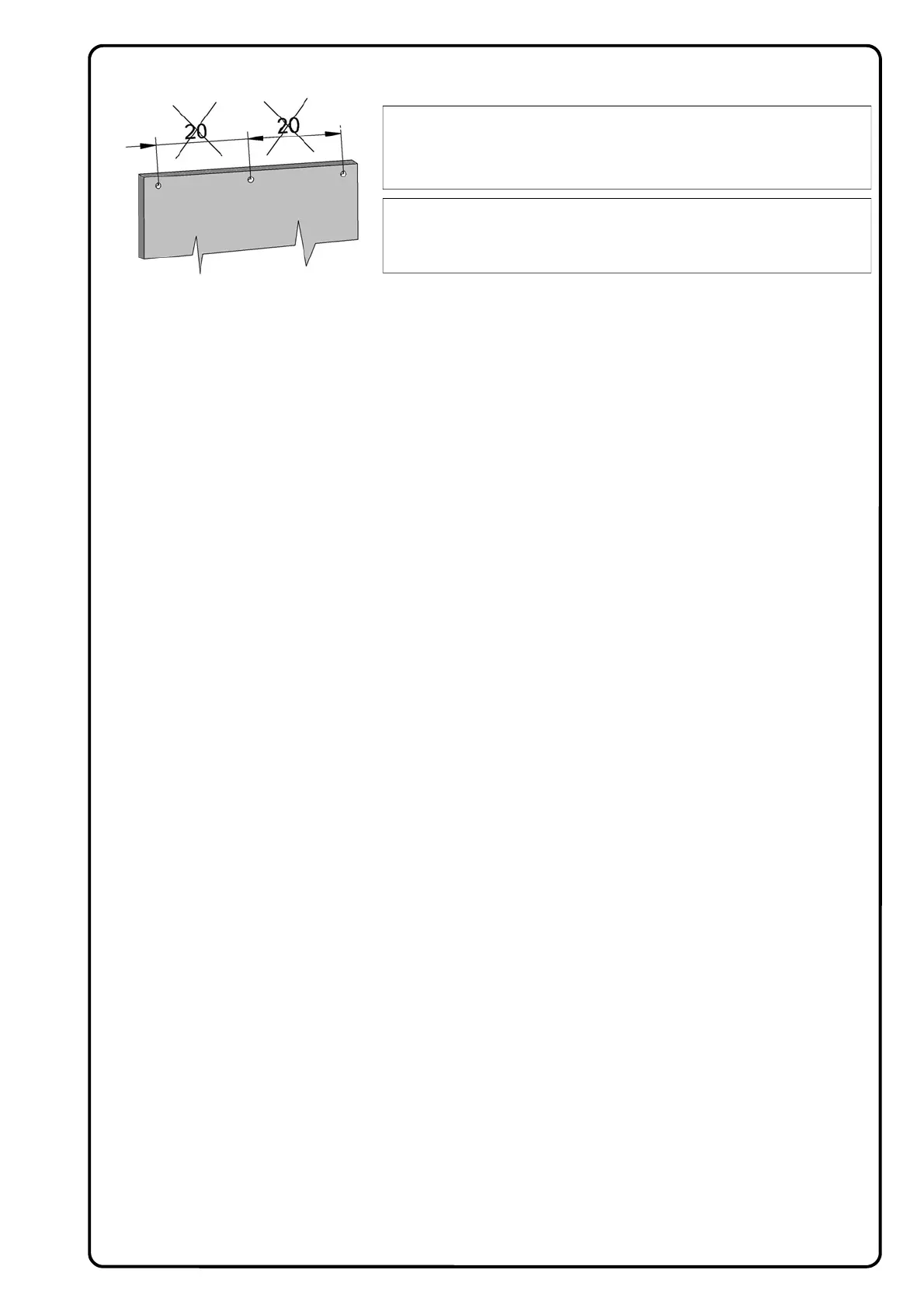

The following results are obtained from the determination of dust emission in 1 hour of continuous work, drill-

i

ng a fir PVC covered panel 20 mm thick. Dust emission turned out 13,9 mg/N cu.m at 1,5 m from ground in

front of the machine in the operator position.

22. PUTTING THE MACHINE OUT OF SERVICE

When machine has to be put out of service, please carefully follow our instructions in order to safeguard the

s

afety of people and of environment. Firstly execute the insulation procedure, then dismantle the drills and put

them into a suitable packaging box. Dismantle electric, hydraulic and pneumatic components so that you

can re-use them after a check or a revision. Empty out completely from oil the hydraulic power unit, avoiding

scrupulously to disperse the oil in the environment. Dismantle metal components grouping them for materials.

Call a specialized company to rescue and eliminate solid and liquid materials.

ACTION

- check locking. Call Service if the locking is good

- replace or call Service

- check clamp units, their seals and working air pressure value

PROBABLE REASON

A - unproper drill locking

B - drill wear

C - working piece unproperly blocked

18.3 THE HOLE IS NOT ACCURATE

Loading...

Loading...