7 ENGLISH

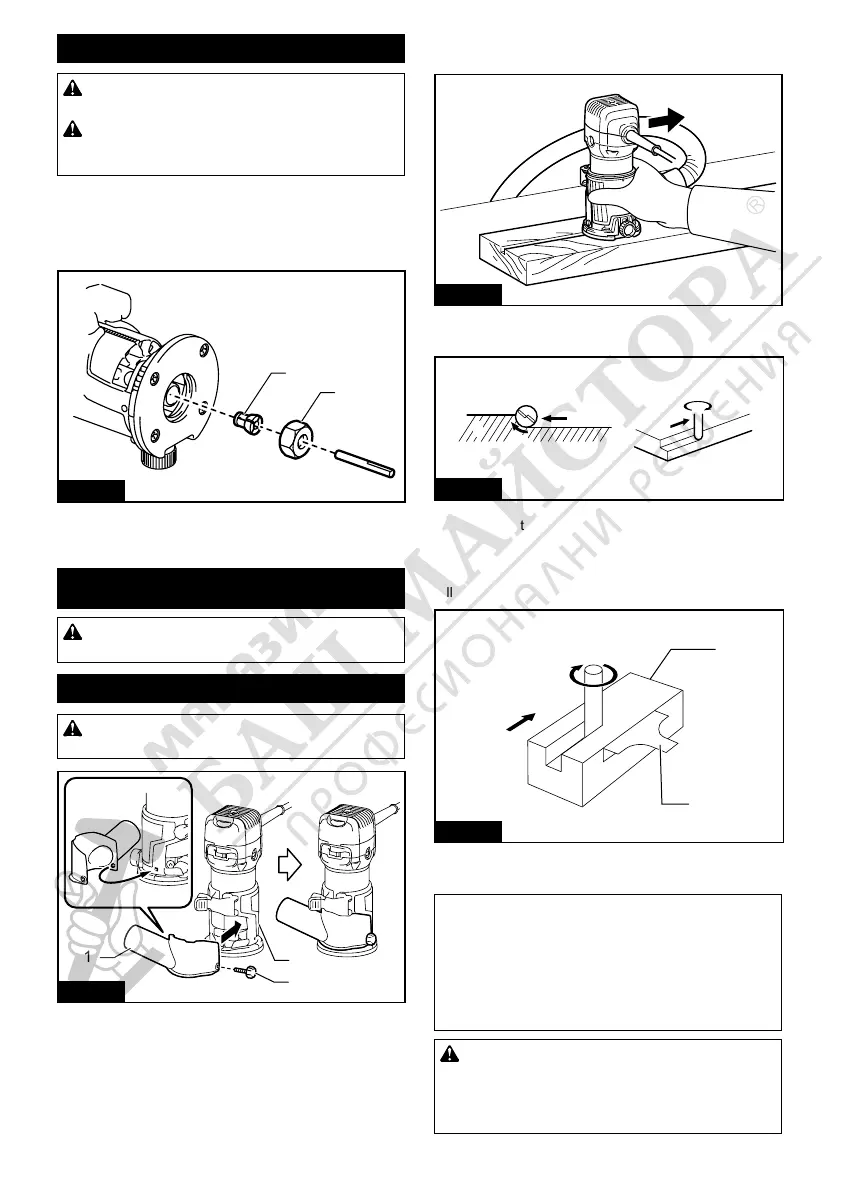

Changing the collet cone

CAUTION: Use the correct size collet cone for

the trimmer bit which you intended to use.

CAUTION: Do not tighten the collet nut with-

out installing a trimmer bit, or the collet cone may

break.

1. Loosen the collet nut and remove.

2. Replace the installed collet cone with desired

collet cone.

3. Reinstall collet nut.

1

2

Fig.7

► 1. Collet cone 2. Collet nut

OPERATION

CAUTION: Always hold the tool rmly with

one hand on housing. Do not touch the metal part.

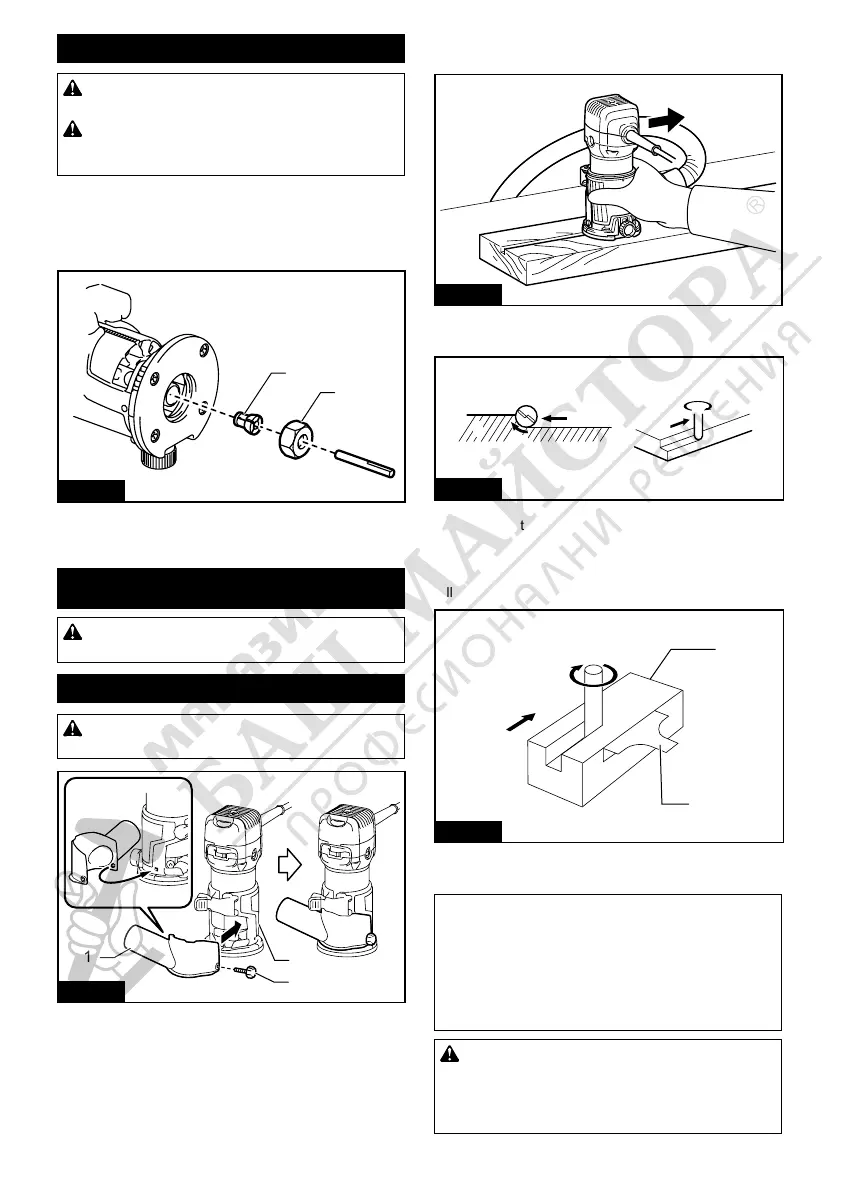

For the base

WARNING: Before using the tool with the

base, always install the dust nozzle on the base.

1

2

3

Fig.8

► 1. Dust nozzle 2. Thumb screw 3. Base

1. Set the base on the workpiece to be cut without

the trimmer bit making any contact.

2. Turn the tool on and wait until the trimmer bit

attains full speed.

3.

Move the tool forward over the workpiece surface, keeping

the base ush and advancing smoothly until the cutting is complete.

Fig.9

When doing edge cutting, the workpiece surface should

be on the left side of the trimmer bit in the feed direction.

1

2

3

4

4

2

Fig.10

► 1. Workpiece 2. Bit revolving direction 3. View from

the top of the tool 4. Feed direction

When using the straight guide or the trimmer guide, be

sure to keep it on the right side in the feed direction. This

will help to keep it ush with the side of the workpiece.

1

2

3

4

Fig.11

► 1. Feed direction 2. Bit revolving direction

3. Workpiece 4. Straight guide

NOTE:

Moving the tool forward too fast may cause a poor

quality of cut, or damage to the trimmer bit or motor. Moving

the tool forward too slowly may burn and mar the cut. The

proper feed rate will depend on the bit size, the kind of

workpiece and depth of cut. Before beginning the cut on the

actual workpiece, it is advisable to make a sample cut on

a piece of scrap lumber. This will show exactly how the cut

will look as well as enable you to check dimensions.

CAUTION:

Since excessive cutting may cause over-

load of the motor or diculty in controlling the tool, the depth

of cut should not be more than 3 mm at a pass when cutting

grooves. When you wish to cut grooves more than 3 mm deep,

make several passes with progressively deeper bit settings.

Loading...

Loading...