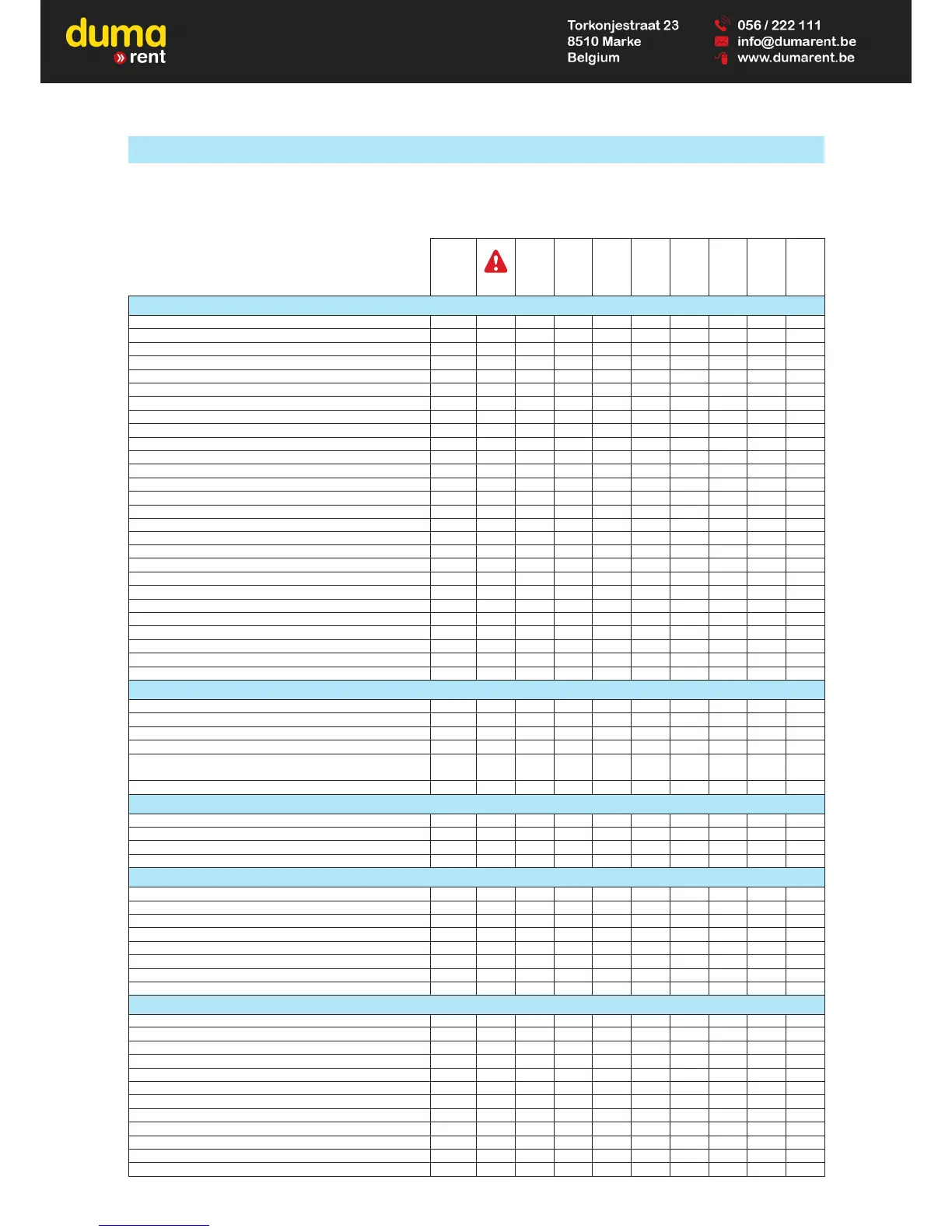

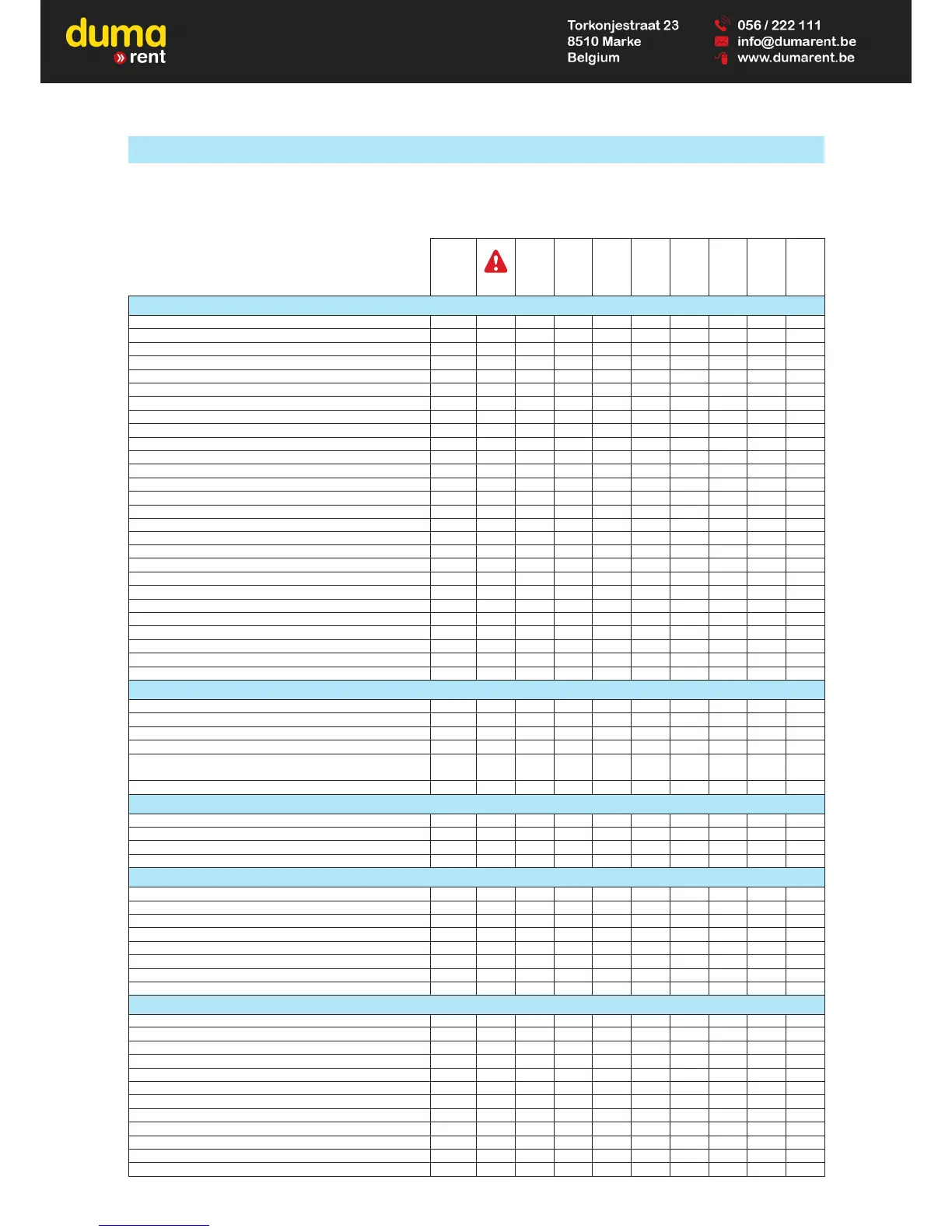

3-10

SERVICING SCHEDULE

(1): MANDATORY 500 HOUR OR 6 MONTH SERVICE

This service must be carried out after approximately the first 500 hours of operation or within the 6 months following the start-up of the machine

(whichever occurs first).

A = ADJUST, C = CHECK, G = GREASE, N = CLEAN,

P = BLEED, R = REPLACE, V = DRAIN

PAGE

(1)

DAILY OR EVERY 10

HOURS SERVICE

EVERY 50 HOURS

SERVICE

EVERY 250 HOURS

SERVICE

EVERY 500 HOURS

SERVICE OR 6

MONTHS

EVERY 1000 HOURS

SERVICE OR 1 YEAR

EVERY 2000 HOURS

SERVICE OR 2

YEARS

EVERY 4000 HOURS

SERVICE

OCCASIONALLY

I.C. ENGINE

I.C. engine oil level

3-12 C C <<< <<< <<< <<< <<< <<<

Cooling liquid level

3-12 C C <<< <<< <<< <<< <<< <<<

Fuel level

3-13 C C <<< <<< <<< <<< <<< <<<

Cyclonic pre-filter (OPTION)

3-13 N N <<< <<< <<< <<< <<< <<<

Dry air filter cartridge

3-14/21 R N <<< R <<< <<< <<<

Radiator core

3-14 N N <<< <<< <<< <<< <<<

Fuel filter

3-18 N N <<< <<< <<< <<<

Alternator/fan/crankshaft belt tension

3-18 A C/A <<< <<< <<< <<<

I.C. engine oil **

3-20 V V <<< <<< <<<

I.C. engine oil filter **

3-20 R R <<< <<< <<<

Fuel filter cartridge

3-21 R R <<< <<< <<<

Fuel pre-filter

3-22 R R <<< <<< <<<

Alternator/fan/crankshaft belt

3-22 R R <<< <<< <<<

Fuel tank

3-24 N <<< <<<

Fuel tank breather

3-24 R <<< <<<

Safety dry air filter cartridge

3-24 R <<< <<<

I.C. engine silent blocks

C* <<< <<<

I.C. engine rates

C* <<< <<<

Valves clearances

C* C* <<< <<<

Cooling liquid

3-28 V <<<

Injection pump

C* <<<

Injectors

C* <<<

Radiator

C* <<<

Water pump and the thermostat

C* <<<

Alternator and the starter motor

C* <<<

Turbocompressor

C* <<<

Fuel circuit

3-30 P

TRANSMISSION

Front wheels reducers oil level

3-14 C C <<< <<< <<< <<< <<<

Front wheels reducers oil

3-29 V V <<<

Hydrostatic transmission circuit pressures

C* <<<

Governing start of the hydrostatic transmission

C* <<<

Working order of the hydraulic valves for the transmission

cut-off and accelerator

C* <<<

Wearing of brake discs

C*

TYRES

Tyre pressure

3-13 C C <<< <<< <<< <<< <<< <<<

Wheel nut torque

3-13 C C <<< <<< <<< <<< <<< <<<

Condition of wheels and tyres

C* <<< <<<

Wheel

3-31 R

MAST

Tension and alignment of the mast lifting chains

3-15 C/A C/A <<< <<< <<< <<< <<<

Mast

3-15 G G <<< <<< <<< <<< <<<

Mast lifting chains

3-23 N/C/G N/C/G <<< C* <<<

Condition of mast unit

C* <<<

Chain rollers

C* <<<

Mast guide rollers

C* <<<

Mast bearing rollers

C* <<<

Thickness of the mast wearing plates

C* <<<

HYDRAULIC

Hydraulic oil level

3-16 C C <<< <<< <<< <<< <<<

Hydraulic return oil filter cartridge

3-23 R R <<< <<< <<<

Hydraulic oil

3-25 V <<< <<<

Suction strainer for hydraulic oil tank

3-25 N <<< <<<

Filter cap for hydraulic oil tank

3-25 R <<< <<<

Speeds of hydraulic movements

C* <<< <<<

Hydraulic pump tubular filter

N* <<< <<<

Condition of hoses and flexible pipes

C* <<< <<<

Condition of cylinders (leakage, shafts)

C* <<< <<<

Hydraulic circuit pressures

C* <<<

Hydraulic circuit outputs

C* <<<

Hydraulic oil tank

N* <<<

Loading...

Loading...