3 - 23

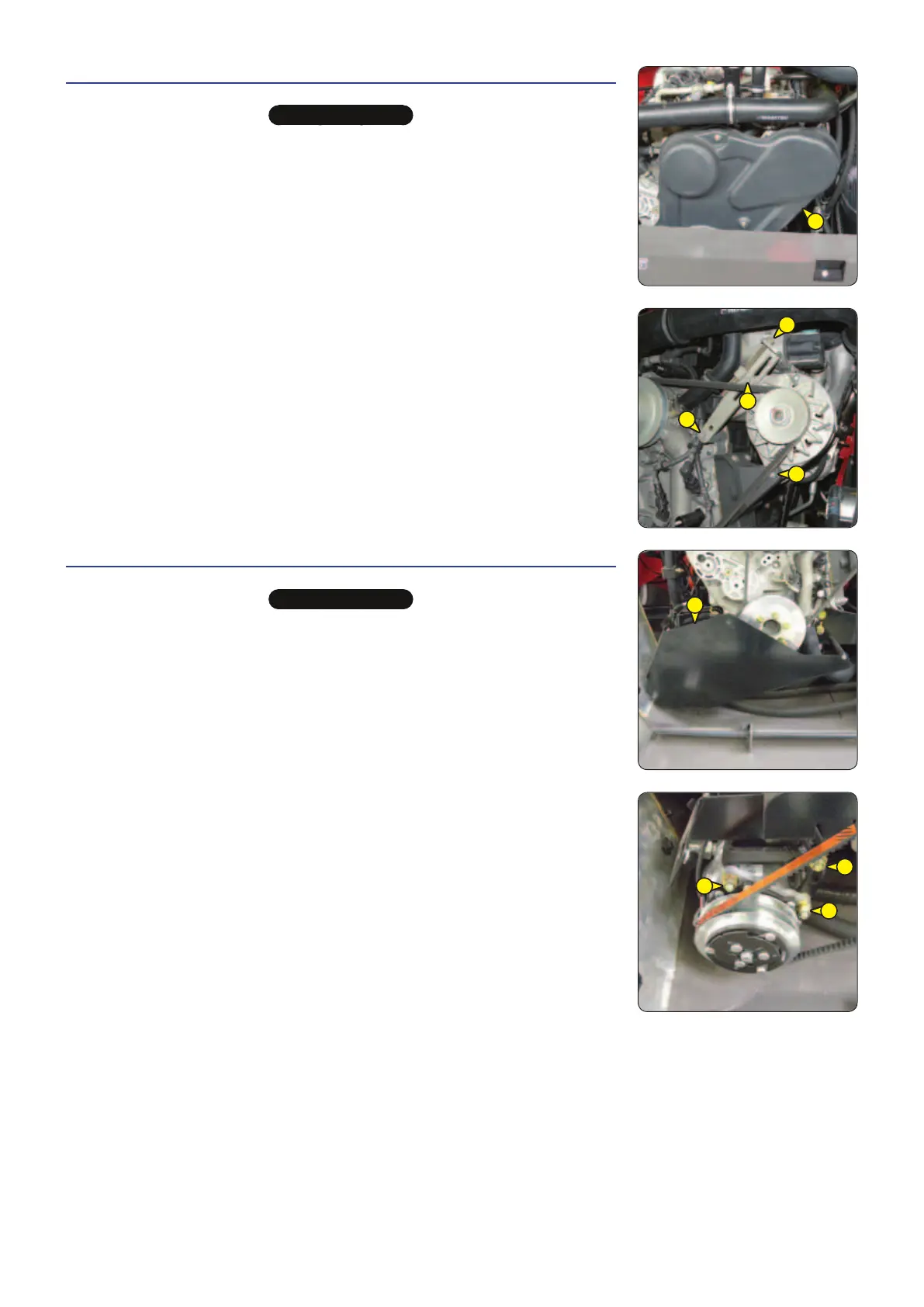

D3 – ALTERNATOR/FAN/CRANKSHAFT BELT TENSION

CHECK - ADJUST

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Open the engine bonnet.

- Remove the protective casing 1.

- Check the belt for signs of wear and cracks and change if necessary (see:

3-MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the crankshaft and alternator pulleys.

- Under a normal pressure exerted with the thumb (45 N), the belt should move

approximately 10 mm.

- Adjust if necessary.

- Loosen the screws 2 and 3 by two to three thread turns.

- Tighten the screw 4 to tighten the belt to the tension required.

- Re-tighten the screws 2 (tightening torque 30 N.m) and the screw 3 (tightening

torque 42 N.m).

- Refit the protective casing 1.

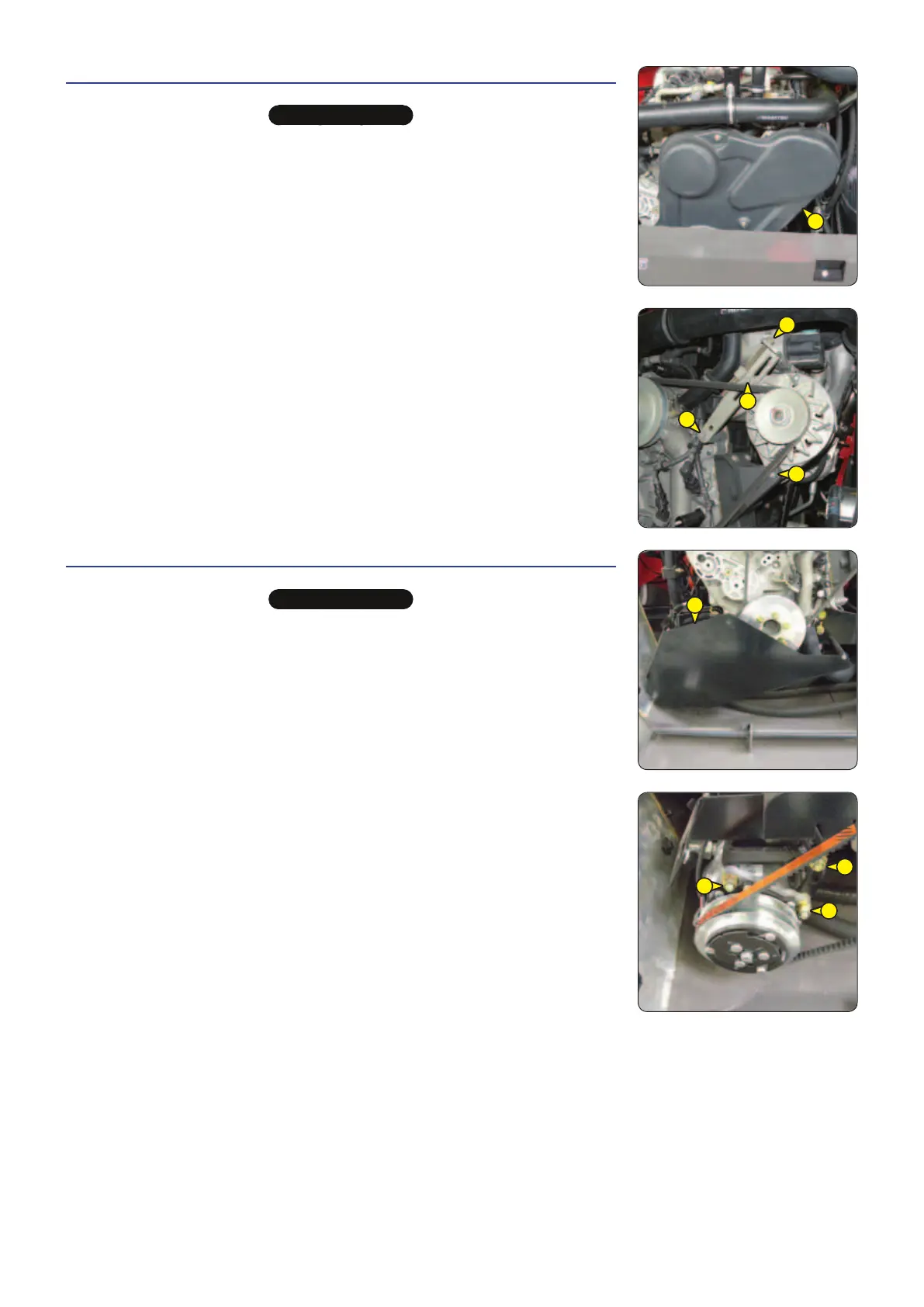

D4 – COMPRESSOR BELT TENSION (AIR-CONDITIONING OPTION)

CHECK - ADJUST

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Open the engine bonnet.

- Lower the bottom cover (OPTION).

- Remove the protective casing 2.

- Check the belt for signs of wear and cracks and change if necessary (see:

3-MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the crankshaft and of the compressor

- Under a normal pressure exerted with the thumb (45 N), the belt should move

approximately 10 mm.

- Adjust if necessary.

- Loosen screws 3 by two to three turns.

- Swivel the compressor assembly so as to obtain the belt tension required.

- Retighten screws 3 (tightening torque 22 N.m).

3

3

3

2

2

3

4

2

1

647563 (22/08/2017)

MT 1435/1440/1840 EASY 75D ST3B S1

Loading...

Loading...