3 - 32

F - EVERY 2000 HOURS OF SERVICE OR EVERY TWO YEARS

Carry out the operations described previously as well as the following operations.

F1 – COOLING LIQUID

DRAIN

These operations are to be carried out as necessary or every two years at the beginning

of winter. Place the lift truck on level ground with the engine stopped and cold.

IMPORTANT

The engine does not contain any corrosion resistor and must be filled throughout the year with a mixture containing

25% ethylene glycol-based antifreeze.

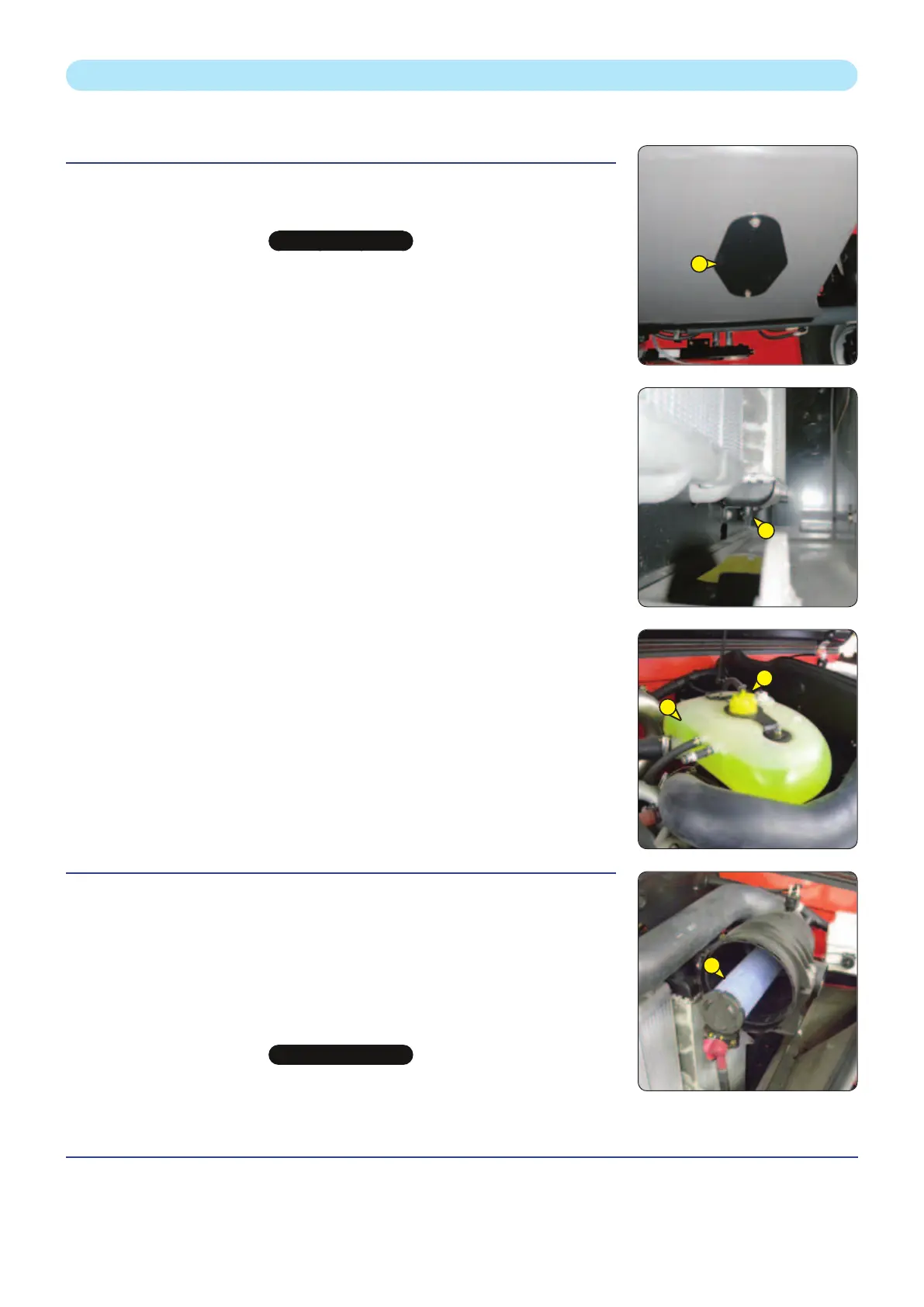

DRAINING THE LIQUID

- Open the engine bonnet.

- Remove access panel 1.

- Place a container under the radiator drain plug 2.

- Remove filler plug 3 from the expansion tank and fully open the heating control

to ensure proper emptying.

- Let the cooling circuit drain entirely while ensuring that the ports do not get clogged.

- Check the condition of the hoses as well as the fastening devices and change the

hoses if necessary.

- Rinse the circuit with clean water and use a cleaning agent if necessary.

FILLING THE LIQUID

- Close the drain valve 2.

- Slowly fill the circuit with cooling liquid through the filler port (see: 3 - MAINTENANCE:

LUBRICANTS AND FUEL) up to the middle of the expansion tank 4.

- Refit the filler plug 3.

- Run the engine at idle for a few minutes.

- Check for any possible leaks.

- Refit access panel 1.

- Check the level and refill if necessary.

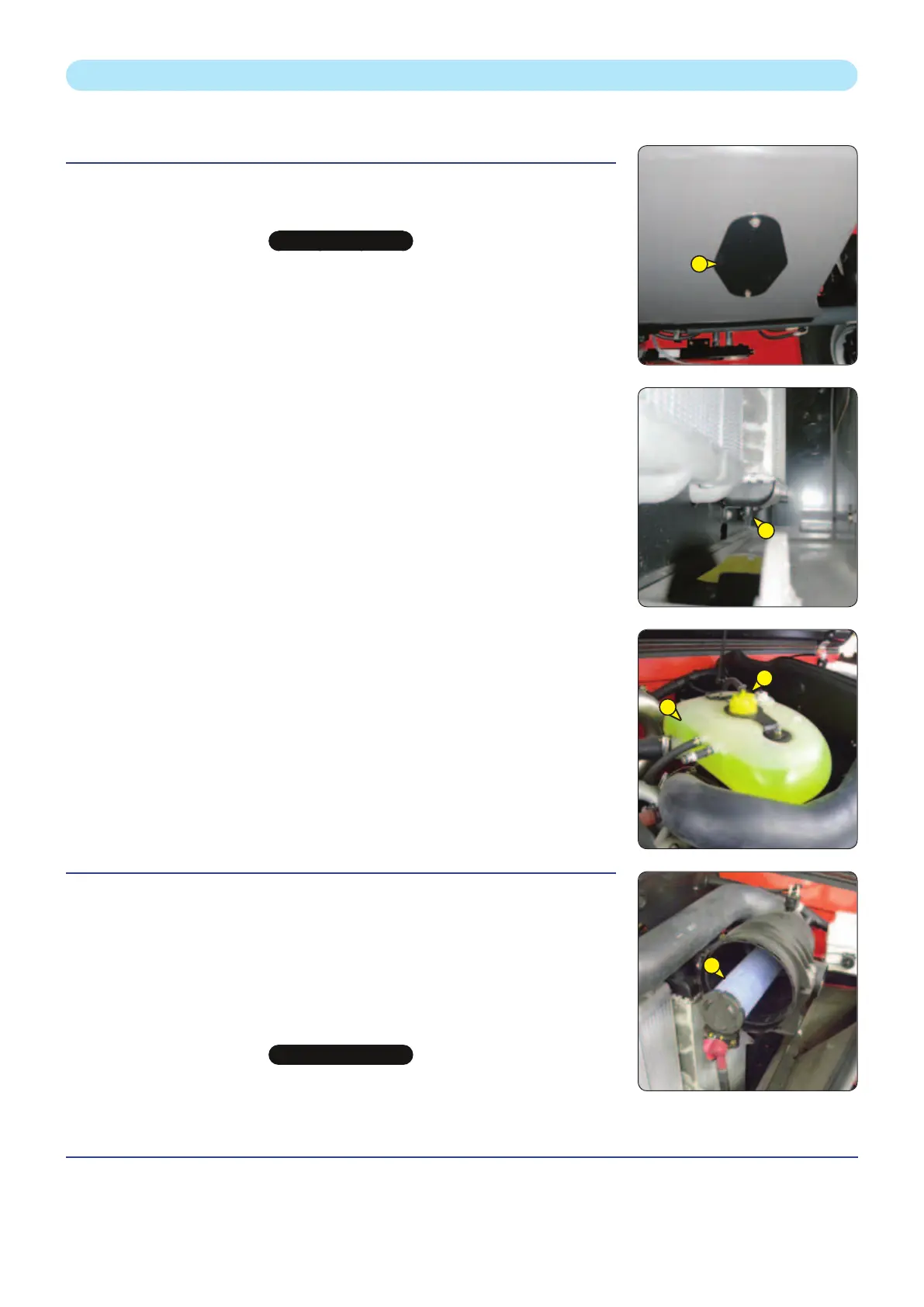

F2 – SAFETY DRY AIR FILTER CARTRIDGE

REPLACE

- For the disassembly and reassembly of the dry air filter cartridge, see:

3-MAINTENANCE: E1 - AIR FILTER CARTRIDGE.

- Gently remove the dry air filter safety cartridge 1, taking care to avoid spilling the dust.

- Clean the gasket surface on the filter with a damp, clean lint-free cloth.

- Check the condition of the new safety cartridge before fitting (see: 3 - MAINTENANCE:

FILTERS AND BELTS).

- Insert the cartridge in the filter axis and push it home, pressing against the outer

edge and not the center.

IMPORTANT

The safety cartridge replacement frequency is given for information only. It must be changed every second time

thedry air filter cartridge is changed.

F3 – WHEEL NUT TIGHTENING TORQUES

CHECK

- Check the condition of the tyres, to detect cuts, blisters, wear, etc.

- Check the tightening torque of the wheel nuts with a torque wrench.

• Front tyres: 630 N.m ± 15 %

• Rear wheels: 630 N.m ± 15%

1

2

3

4

1

647563 (22/08/2017)

MT 1435/1440/1840 EASY 75D ST3B S1

Loading...

Loading...