NATIONAL CRANE Published 9-26-2018 Control # 646-02 4-13

NTC55 OPERATOR MANUAL SET-UP

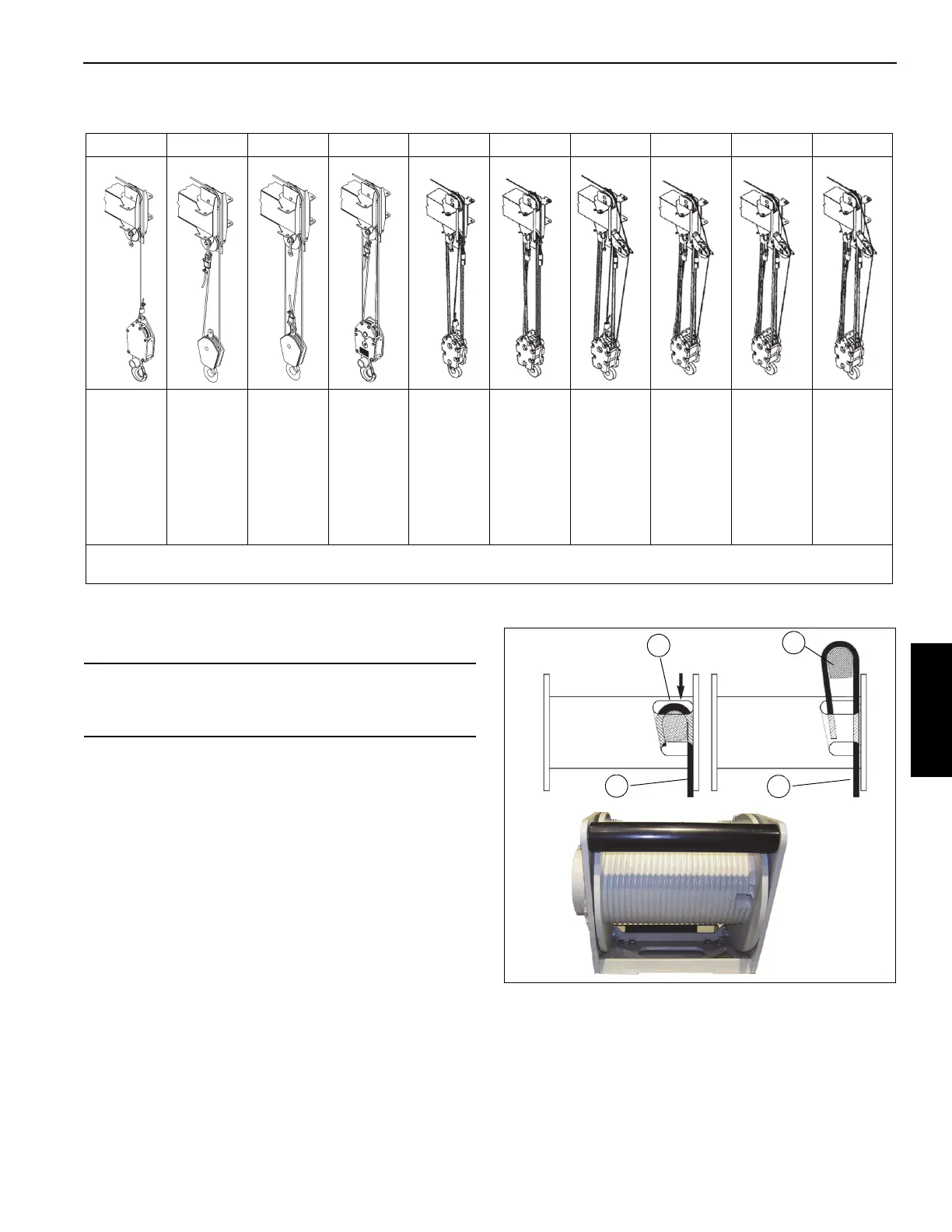

INSTALLING CABLE ON THE HOIST

NOTE: The cable should preferably be straightened before

installation on the hoist drum.

Install cable on the hoist drum in accordance with the

following procedure:

1. Position the cable over the boom nose sheave and route

to the hoist drum.

2. Position the hoist drum with the cable anchor slot on top.

3. Insert the cable through the slot and position around the

anchor wedge (1) Figure 4-7.

NOTE: The end of the cable should be even with the

bottom of the slot for the anchor wedge.

4. Position the anchor wedge in the drum slot; pull firmly on

the free end (2) of the cable to secure the wedge.

NOTE: If the wedge does not seat securely in the slot,

carefully tap (3) the top of the wedge with a mallet.

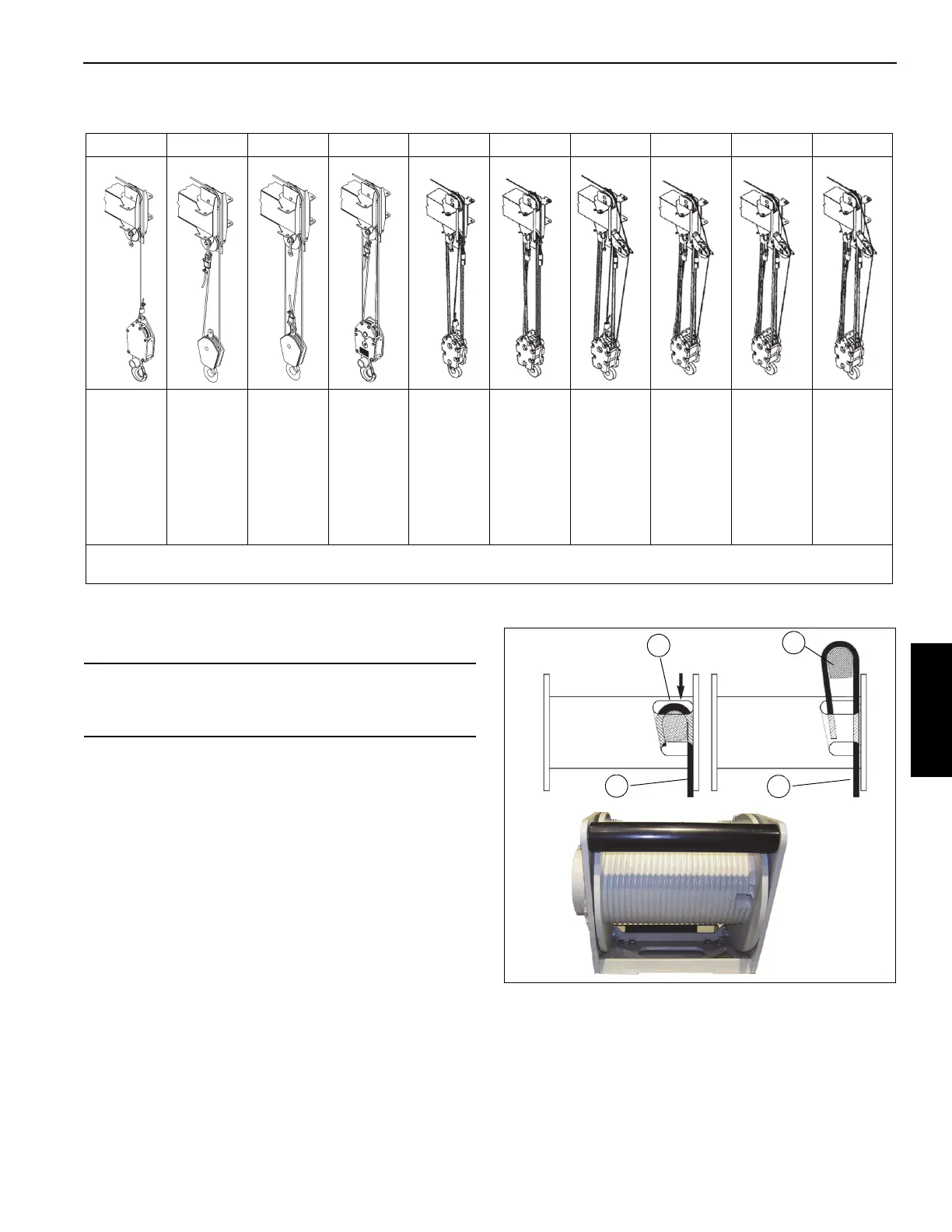

1 Part Line 2 Part Line 3 Part Line 4 Part Line 5 Part Line 6 Part Line 7 Part Line 8 Part Line 9 Part Line 10 Part Line

Maximum

Pull

Normal

Speed

11,250 lbs

191 fpm

High Speed

5,600 Lbs

383 fpm

Maximum

Pull

Normal

Speed

22,500 Lbs

95 fpm

High Speed

11,200 Lbs

191 fpm

Maximum

Pull

Normal

Speed

33,750 Lbs

63 fpm

High Speed

16,800 Lbs

127 fpm

Maximum

Pull

Normal

Speed

45,000 Lbs

47 fpm

High Speed

22,400 Lbs

95 fpm

Maximum

Pull

Normal

Speed

56,250 Lbs

38 fpm

High Speed

28,000 Lbs

76 fpm

Maximum

Pull

Normal

Speed

67,650 Lbs

31 fpm

High Speed

33,600 Lbs

63 fpm

Maximum

Pull

Normal

Speed

78,750 Lbs

27 fpm

High Speed

39,200 Lbs

54 fpm

Maximum

Pull

Normal

Speed

90,000 Lbs

23 fpm

High Speed

44,800 Lbs

47 fpm

Maximum

Pull

Normal

Speed

100,000 Lbs

21 fpm

High Speed

50,400 Lbs

42 fpm

Maximum

Pull

Normal

Speed

110,000 Lbs

19 fpm

High Speed

56,000 Lbs

38 fpm

The hook block must be sized to the number of line parts. For example, do not use a six part line hook block on a three part line reeving. Contact

your National Crane Distributor or Manitowoc Crane Care to order the proper hook block.

CAUTION

If cable is wound from the storage drum, the reel should

be rotated in the same direction as the hoist.

Loading...

Loading...