SET-UP OPERATOR MANUAL NTC55

4-2 Published 9-26-2018 Control # 646-02

3. Place a miracle pointer level, carpenter level, or similar

type device on a machined surface such as the turntable

bearing or bearing mounting surfaces.

4. Using the outriggers, level the crane as indicated on the

leveling device used in step 3.

5. Ensure the cab tilt is completely lowered (if equipped).

6. Using the bubble level indicator mounting screws, adjust

the bubble level indicator to show level.

Site Selection

The outrigger floats must be on a firm solid surface that is

level. The surface must keep the crane stable and not allow

the stabilizer float to sink or slide. Avoid areas that are:

• uneven

• rocky

• muddy

Setting the Outriggers

The outrigger setup procedure is as follows:

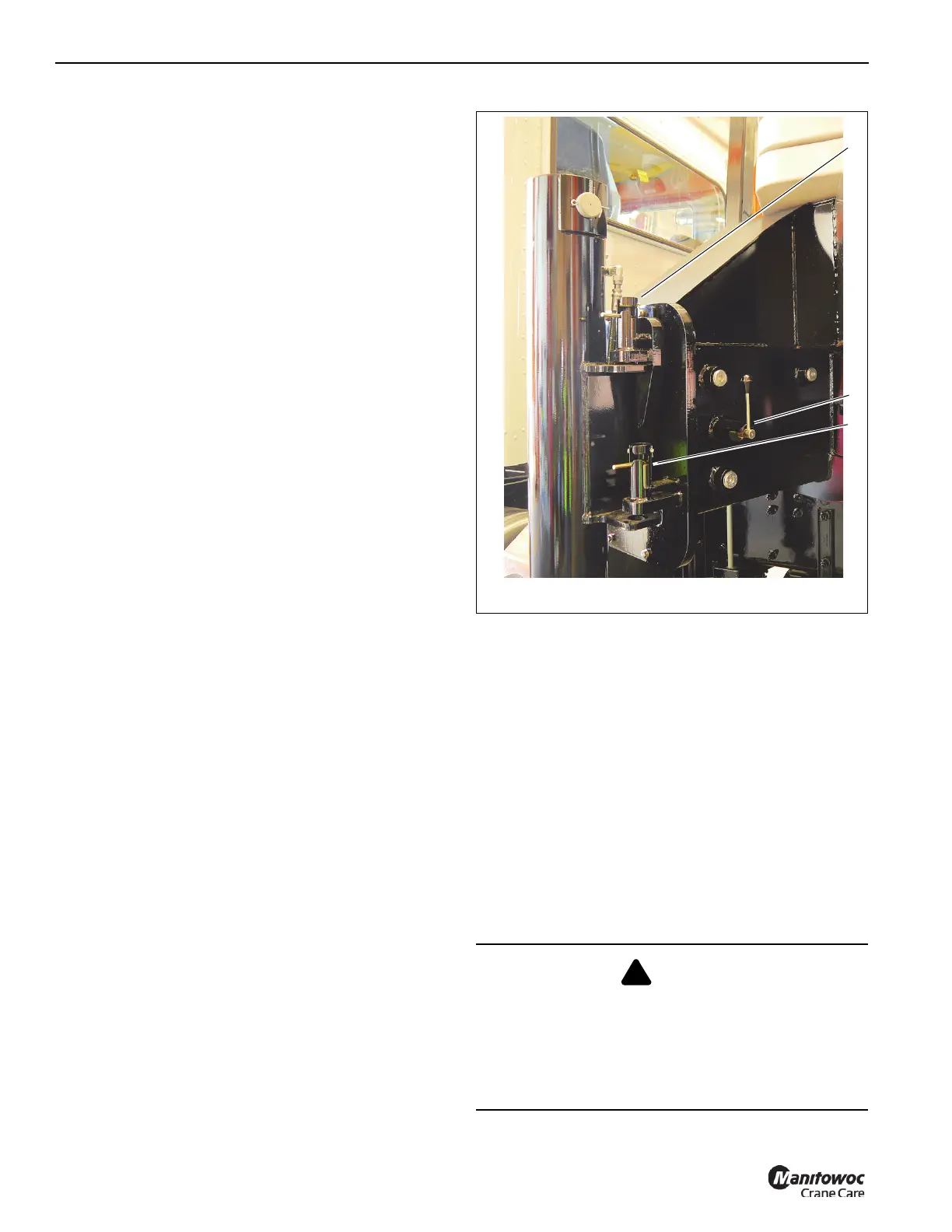

1. Disengage the mechanical travel lock (1, Figure 4-1)

that secures each outrigger beam in the fully retracted

position during travel.

NOTE: To ensure a true reading always make sure the cab

tilt is completely lowered.

2. Operate the ground station or cab outrigger control

panel

(Figure 3-1).

3. Select the desired outrigger beam with the extension

button and press the extend button to extend the

outrigger beams.

4. Set all four outrigger beams to desired position:

a. 0% extended position. Does not require the

outrigger beams to be extended.

b. 50% extended position. Engage the manual over-

center locks (2, Figure 4-1) for the midpoint position.

c. 75% extended position. Engage the manual locks

(3, Figure 4-1) by rotating the handle CW.

d. Fully extended position. All locks should be

disengaged for the fully extended position.

DANGER

All four outriggers must either be fully retracted, at the

midpoint, or fully extended, and the RCL set to the correct

position. Failure to do so creates a tipping hazard.

Do NOT use position locks in combination. Using more

than one position lock at a time may result in an undesired

span.

Loading...

Loading...