4-5

Section 4 Maintenance

Water Dump Valve

The water dump valve normally does not require

removal for cleaning.

To determine if removal is necessary:

1. Locate the water dump valve.

2. Set the toggle switch to ICE.

3. While the ice machine is in the freeze mode,

check the dump valve’s clear plastic outlet drain

hose for leakage.

A. If the dump valve is leaking, remove,

disassemble and clean it.

B. If the dump valve is not leaking, do not

remove it. Instead, follow the “Cleaning

Procedure” on page 4-2.

Follow the procedure below to remove the dump

valve.

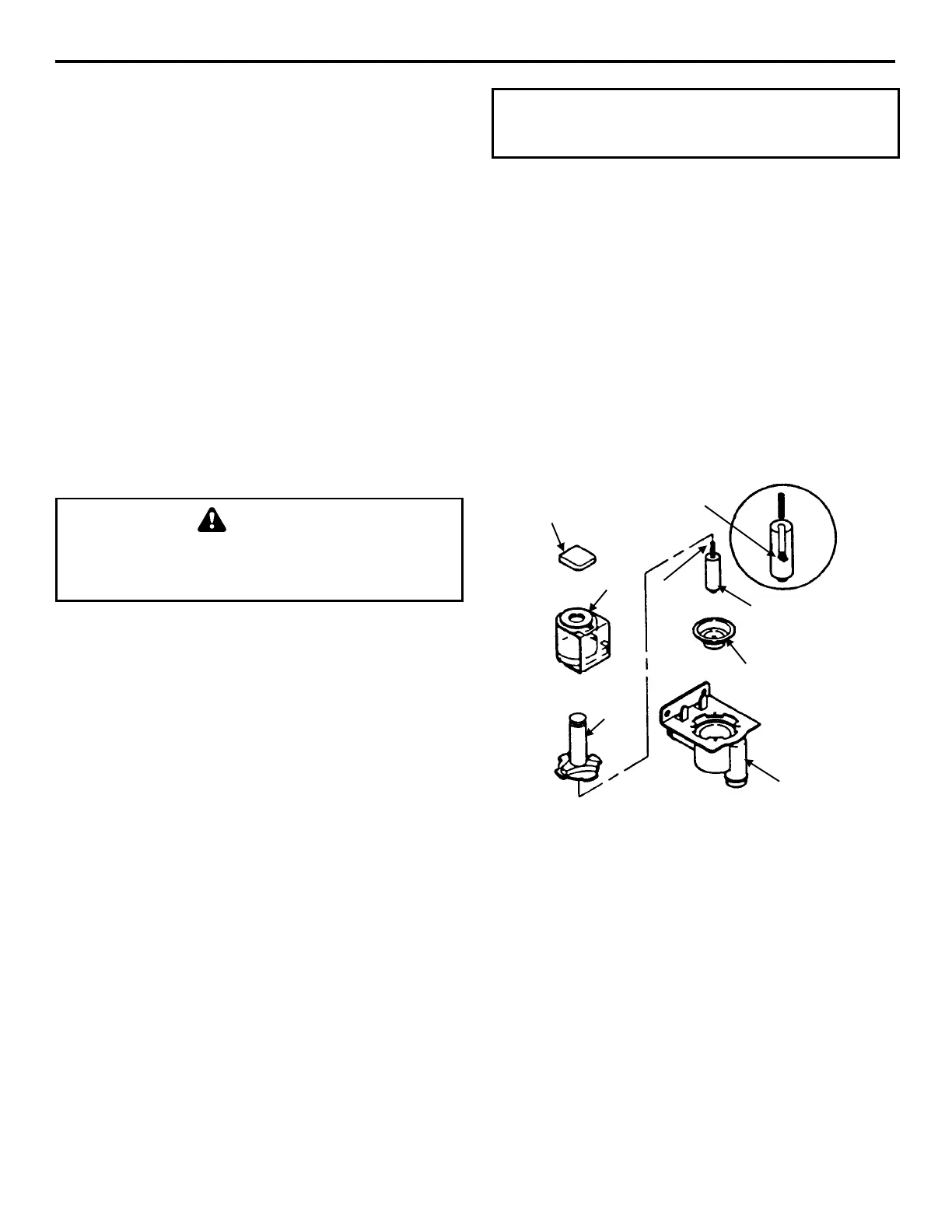

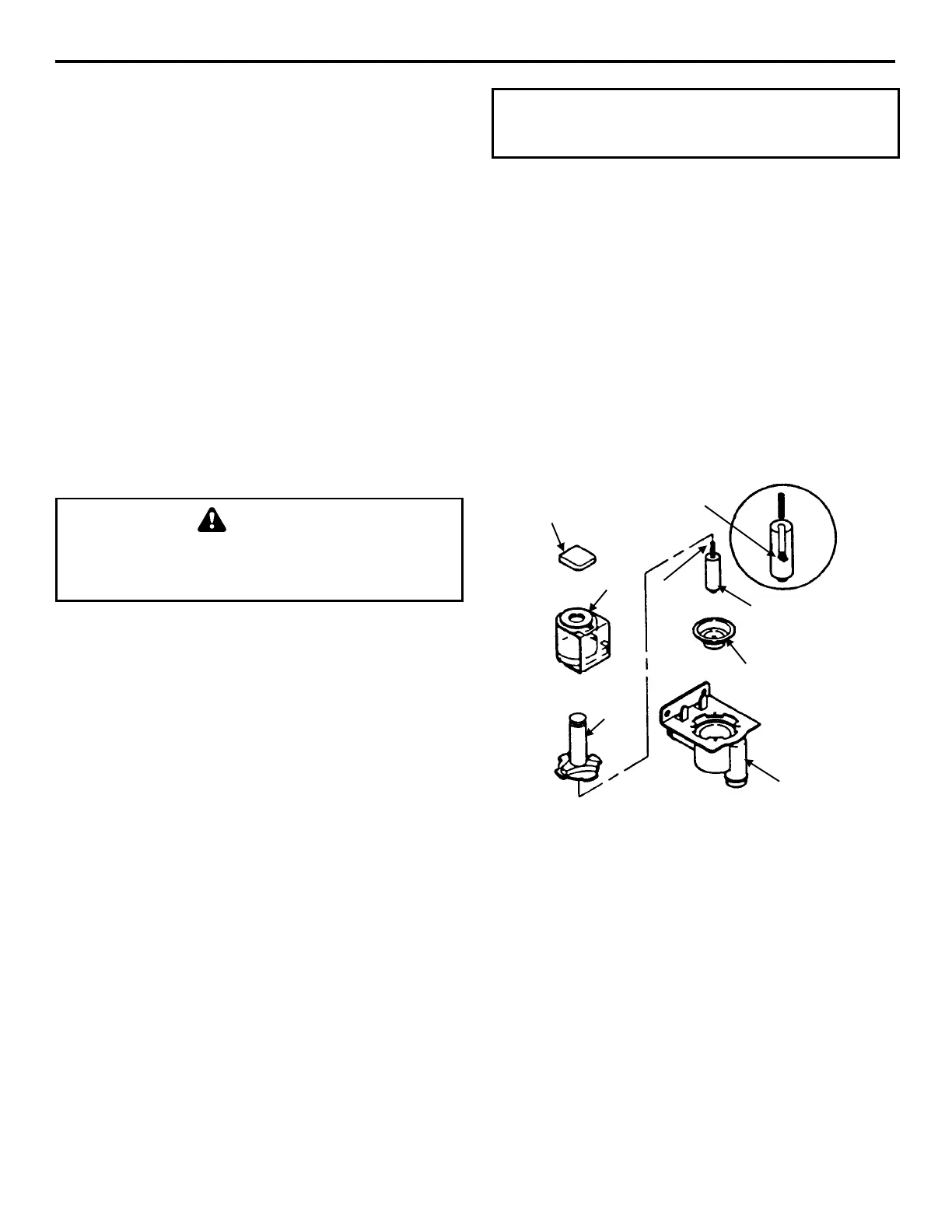

Dump Valve Removal

WARNING

Disconnect the electric power to the ice machine at

the electric service switch box and turn off the

water supply before proceeding.

1. If so equipped, remove the water dump valve

shield from its mounting bracket.

2. Lift and slide the coil retainer cap from the top of

the coil.

3. Note the position of the coil assembly on the

valve for assembly later. Leaving the wires

attached, lift the coil assembly off the valve body

and the enclosing tube.

4. Press down on the plastic nut on the enclosing

tube and rotate it 1/4 turn. Remove the enclosing

tube, plunger, and plastic gasket from the valve

body.

NOTE: At this point, the water dump valve can easily

be cleaned. If complete removal is desired, continue

with step 5.

Important

The plunger and the inside of the enclosing tube

must be completely dry before assembly.

NOTE: During cleaning, do not stretch, damage or

remove the spring from the plunger. If it is removed,

slide the spring’s flared end into the plunger’s slotted

top opening until the spring contacts the plunger

spring stop.

5. Remove the valve body.

6. Remove the tubing from the dump valve by

twisting the clamps off.

7. Remove the two screws securing the dump valve

and the mounting bracket.

Dump Valve Disassembly

CAP

COIL

ENCLOSING

TUBE

PLUNGER

SPRING STOP

DIAPHRAM

VALVE BODY

SPRING

PLUNGER

Loading...

Loading...