18 Operator’s Manual

Mantis

®

XP Tiller Maintenance (Continued)

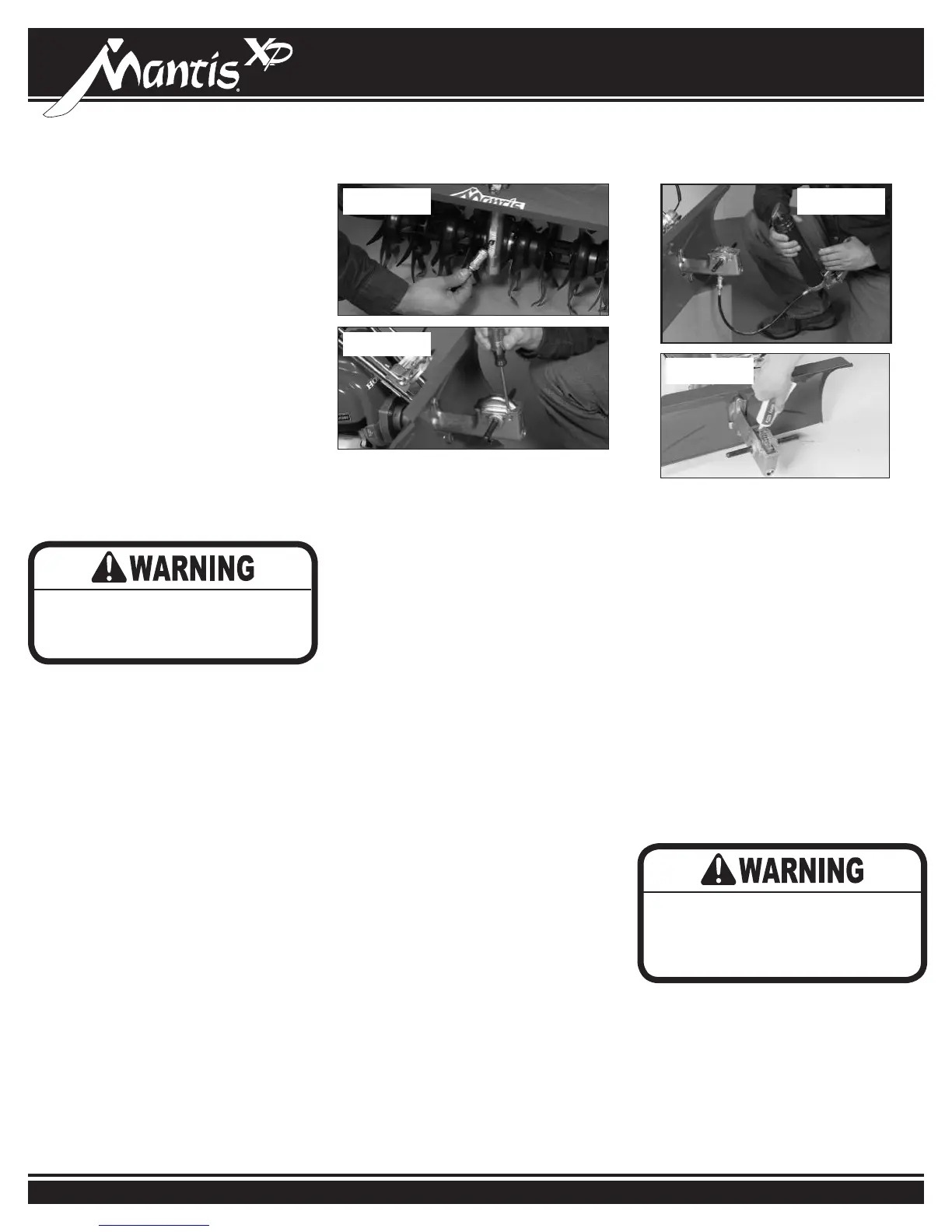

How to Check the Grease Level

Inside the Worm Gear Housing

When we built your Mantis

®

XP Tiller, we

added Lithium EP #0 grease to properly

lubricate the transmission for the rst 10

hours of operation. As part of the regular

maintenance of your tiller, it is imperative

that you inspect the grease level and add

grease if necessary. This will help your

tiller give you years of excellent usage.

You will need to add grease with a

grease gun using the tting at the front of

the transmission (Figure 1). You should

add grease through this tting after the

rst 10 hours of operation and then every

50 hours of use.

You can use Lithium EP#0 EP#1

grease or #2 grease in combination with

specially formulated Mantis

®

grease (p/n

9985).

The following are different service steps

for different type of grease.

IF YOU USE Lithium EP #1 or #0

grease:

1. Make sure the tiller is turned off and

remove the tines.

2. Place the tiller front side down on an

elevated surface and remove the 4

screws holding the transmission cover

(Figure 2).

3. Remove the transmission cover and

gasket. Inspect the grease level. If it

is below the edge of the gear housing,

you will need to add grease. If it is

already ush with this edge, you do

not need to add grease.

4. If grease is needed, remove the

protective cap from the grease tting,

attach the grease gun, and slowly add

grease until the level is ush with the

edge of the transmission (Figure 3).

5. Return the grease tting protective

cover, gasket and attach transmission

cover with the 4 original screws.

IF YOU USE Lithium EP #2 grease

in combination with Mantis

®

grease

(p/n 9985):

Follow steps 1 through 3 and then follow

instructions below.

4. If grease is needed, remove protective

cap from the grease tting on the front

of the transmission and attach the

grease gun. Please pay attention to

the size of the grease gun. Different

guns distribute different amount of

grease per pump.

a. If you are using Mini grease gun

with 3 ounce cartridge add 5

full pumps of grease. One pump

from Mini grease gun is equal to

approximately 0.012 oz. or 0.3

grams.

b. If you are using standard

automotive grease gun with 14

ounce cartridge, add 2 full pumps of

grease. One pump from a standard

automotive grease gun is equal to

0.03 oz. or 0.9 grams.

CAUTION: DO NOT ADD MORE

GREASE THAN SPECIFIED ABOVE

5. Remove the grease gun from

the grease tting and replace the

protective cap.

In between adding grease with the

grease gun, you should inspect the

grease level after approximately 10

hours of operation. If grease is needed,

you can add grease directly to the

opening in the transmission using

Mantis

®

p/n 9985.

6. Inspect the grease level. If it is below

the edge of the gear housing, you will

need to add grease. If it is ush with

the gear housing do not add grease.

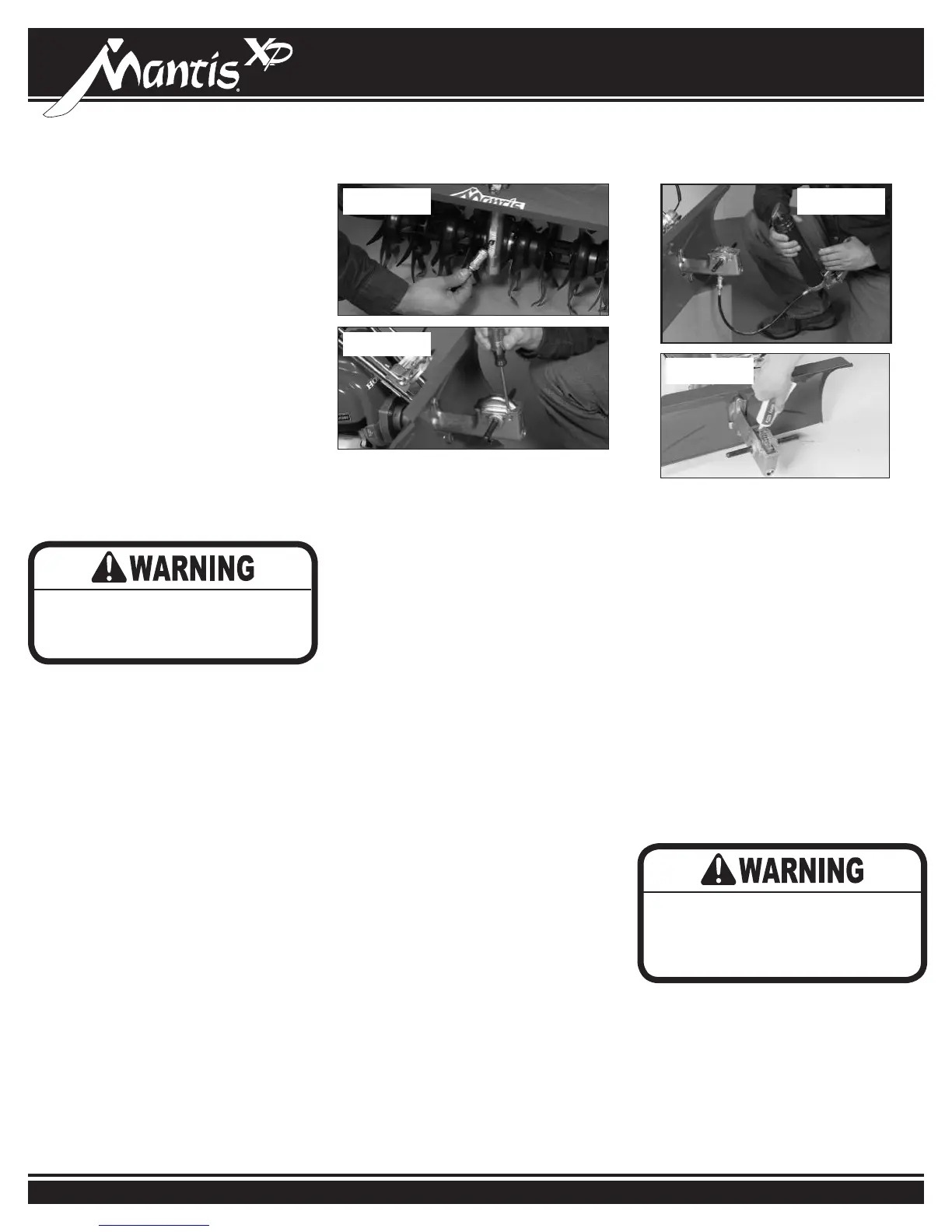

7. If you need to add more grease,

utilize the specially formulated Mantis

grease (p/n 9985). This grease is

compatible with the grease that was

in the transmission from the factory.

DO NOT USE Lithium EP #2 IN THIS

STEP. (Figure 4)

8. Return the gasket and the

transmission cover. Secure cover with

the 4 original screws.

Always inspect the gasket prior to re-

installation. If the gasket is damaged,

replace it with a new gasket (p/n 436)

TRANSMISSION CARE

Figure 4

Premature transmission failure can

occur if proper grease level is

not maintained

DO NOT OVERFILL.

Too much grease can create

pressure which can cause seals

to fail or the clutch to slip.

Figure 1

Figure 2

Figure 3

Loading...

Loading...