Model ESM301 / ESM301L Test Stand User’s Guide

23

For non-relaxing materials such as metal springs, the oscillation should stop shortly after the holding force

is reached.

Note:

Preload and Load Holding cannot be enabled simultaneously.

5.7 Break Detection Mode

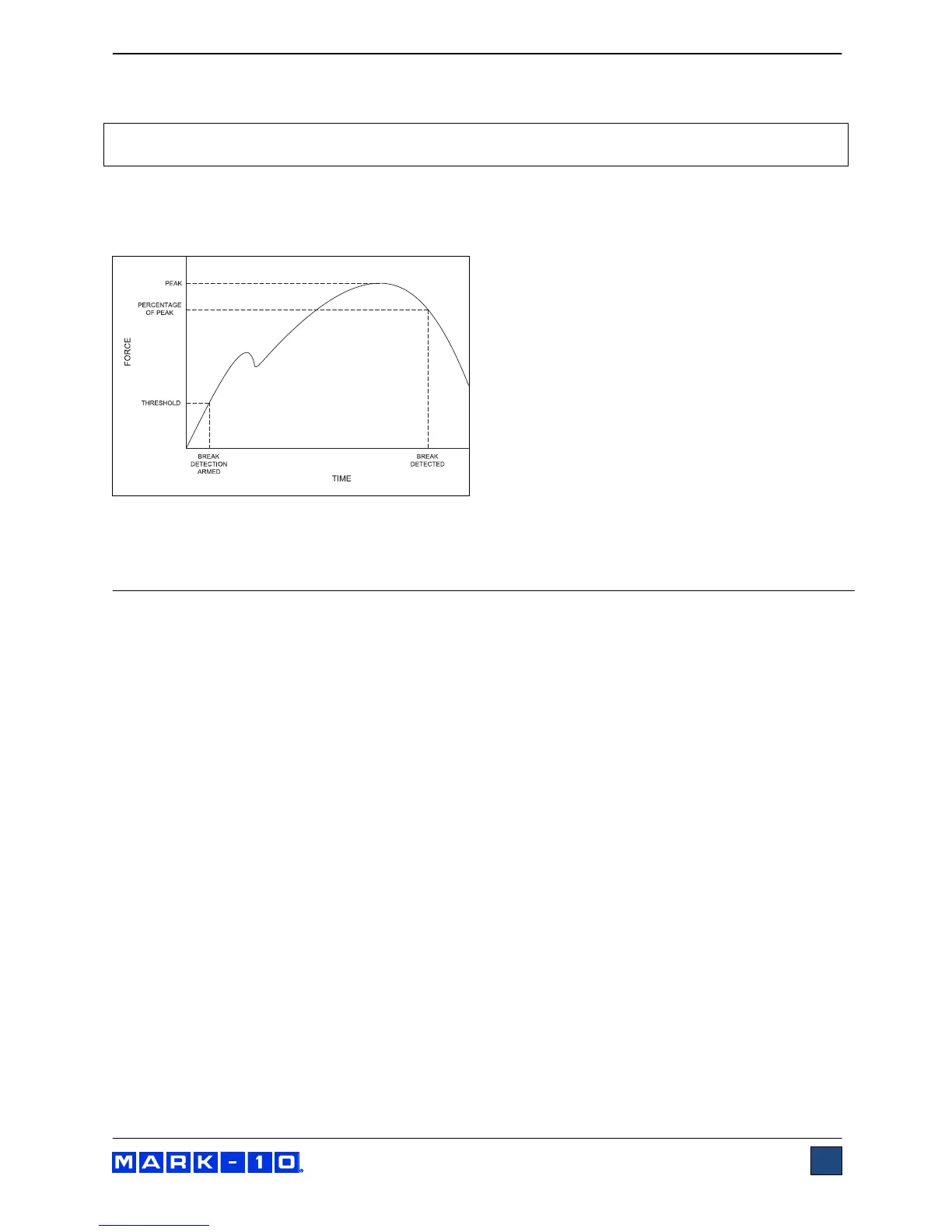

In this mode, the crosshead will stop when a sample break has occurred. This action occurs when the

force has decreased to a specified percentage of peak, as illustrated below:

If enabled, an auto-return sequence or single-cycle sequence may follow break detection.

6 COMMUNICATION

6.1 Setup

The ESM301 can transmit force and travel (optional) data to a PC. The following settings are required for

proper functioning of all test stand functions and data output:

Force gauge / indicator (Series 5 / 7 only):

- RS-232 communication

- 9,600 baud rate

ESM301 test stand menu:

- CONTROL: CONSOLE (this menu is only shown if the PC Control function is installed; PC

Control is not required for data output)

- STOP & PAR (stop bits and parity): 8-1n (8 data bits, one stop bit, no parity)

Connection cables:

- Gauge / indicator to test stand: Part no. 09-1162

- Test stand to RS-232: Part no. 09-1056

- Optional RS-232 > USB converter: Part no. RSU100

If not using Mark-10 data collection software, ensure that the software’s communication settings match. A

number of data collection commands are available, highlighted in blue in the following section.

Loading...

Loading...