4

ELECTRICAL CONNECTIONS

WARNING:

ELECTRICAL SHOCK HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

to the unit.

disconnecting. Reconnect wires correctly.

Electrical Power Wiring

Electrical power wiring shall comply with the current

provisionsoftheNationalElectricalCode(ANSI/NFPA70)as

supplemented by applicable local building codes. The installer

shouldbecomefamiliarwiththewiringdiagrambeforemaking

electrical connections to the outdoor unit. An equipment wiring

diagram is included in this instruction (Figure 8 (page 14)

& Figure 9 (page 15) and inside the unit control panel

cover. Refer to the unit rating label located on the exterior of

the control box cover for operating voltage, minimum circuit

ampacity, and maximum fuse size. See Table 1 for wire sizing.

• Electricalconnectionstotheairconditioneraremadeat

the bottom of the control panel compartment. Remove the

control panel cover to gain access to this compartment.

Figure 2 (page 11) shows a typical control panel

compartment.

• Aproperlysizedbranchcircuitanddisconnectswitchmust

be installed where it is easily accessible and within line of

sight of the outdoor unit.

• Remove the control panel cover. Route the power and

ground wires (3 wires, including earth ground) from the

disconnect box to the unit. Use of outdoor shielded conduit

(metal lined Sealtite®) is required. The electrical conduit

opening is located on the right side of the panel forming

the bottom of the control compartment. See Figure2.

• Connect the powerwiresto L1 and L2 box lugs of the

contactor, and the ground wire to the grounding lug located

to the right of the contactor. Refer to Figure2 and Figure

3 (page 12). Only copper wires should be used.

• Replacethecontrolpanelcoverbeforeapplyingpower.

Control Circuit Wiring

The air conditioner is designed to operate with a 24 vac Class

II control circuit. Control circuit wiring must comply with the

latestversionoftheNationalElectricalCode(ANSI/NFPA70)

as supplemented by local building codes.

In general, 24 vac control power wiring must be run to

interconnect the two-stage thermostat, the indoor unit, and

the outdoor unit. The source of the 24 vac is located within the

indoor unit (air handler or furnace). The C side of this power

source may be grounded or ungrounded, typically determined

by the indoor equipment electrical design.

Fourcontrolwiresmustberuntotheairconditioner’scontrol

panel:R and C will originate from the indoor unit (furnace or

air handler). Y1 and Y2 will originate at the thermostat.

Pass each field-run control wire into the hole in the lower left side

ofthebaseoftheairconditioner’scontrolpanelcompartment.

Refer to Figure2 and Figure4(page12). Connect each of

the field-run wires to its corresponding factory wired lead (with

stripped ends) using a wire nut or other solderless connector

within the low voltage compartment. See Table 2 below.

REFRIGERANT LINE CONNECTIONS

Line Design and Routing

Refrigerant lines must be connected by a licensed EPA certified

technician following sound established installation practice.

Once the air conditioner location has been determined and

the unit set in place the refrigerant lines should be routed

and connected.

• Refrigerantlinesshouldfollowadirectpathfromtheindoor

coil to the outdoor unit avoiding sharp bends. When lines

passthroughwalls,makesuretoproperlysealandsupport

them so that vibration is not transmitted to the structure.

• Refrigeranttubingshouldbesupportedinamannerwhich

assures that the tubing will not vibrate or wear as a result

of contact with sharp materials or edges during system

operation.

• Linesmustbecleanrefrigeration-gradecopper.

• Avoidremovingcapsandplugsfromairconditionervalves

or lines until they are ready to be connected.

• Insulatethevaporlinewithrefrigerantlineinsulationwall

thickness¼”orgreater.

Proper system performance and oil management depend

on properly selecting the liquid and vapor line sizes. Refer to

Table 3 below for the proper size of field supplied lines. The

maximum allowable refrigerant line length is 100 ft.

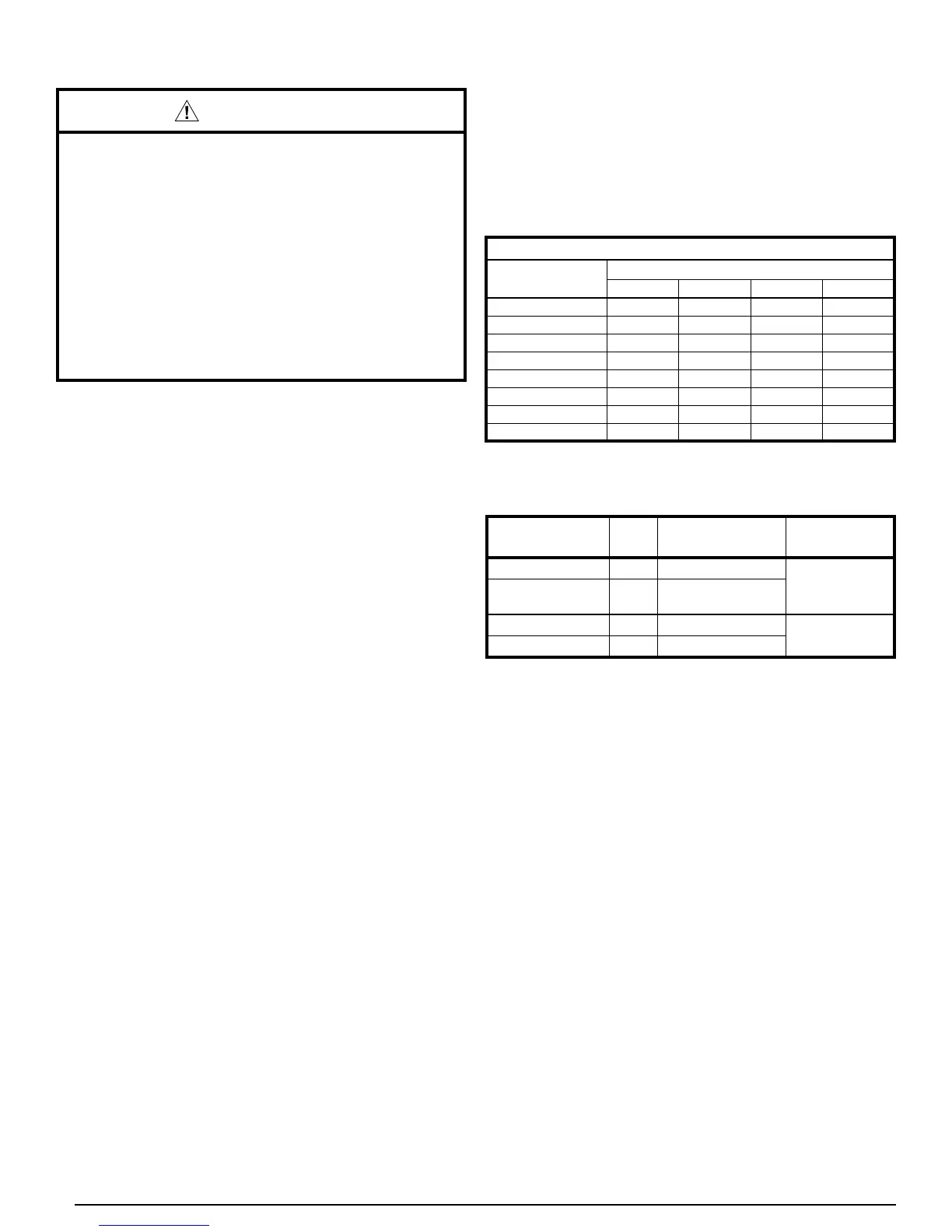

SUPPLY CIRCUIT

AMPACITY

SUPPLY WIRE LENGTH - FT

UP TO 50 51 - 100 101 - 150 151 - 200

15 14 10 8 6

20 12 8 6 4

25 10 8 6 4

30 10 6 4 4

35 8 6 4 3

40 8 6 4 3

45 6 4 3 2

50 6 4 3 2

Wire Sized based on N.E.C. for 60°C type copper conductors

Table 1. Copper Wire Ampacity Tables

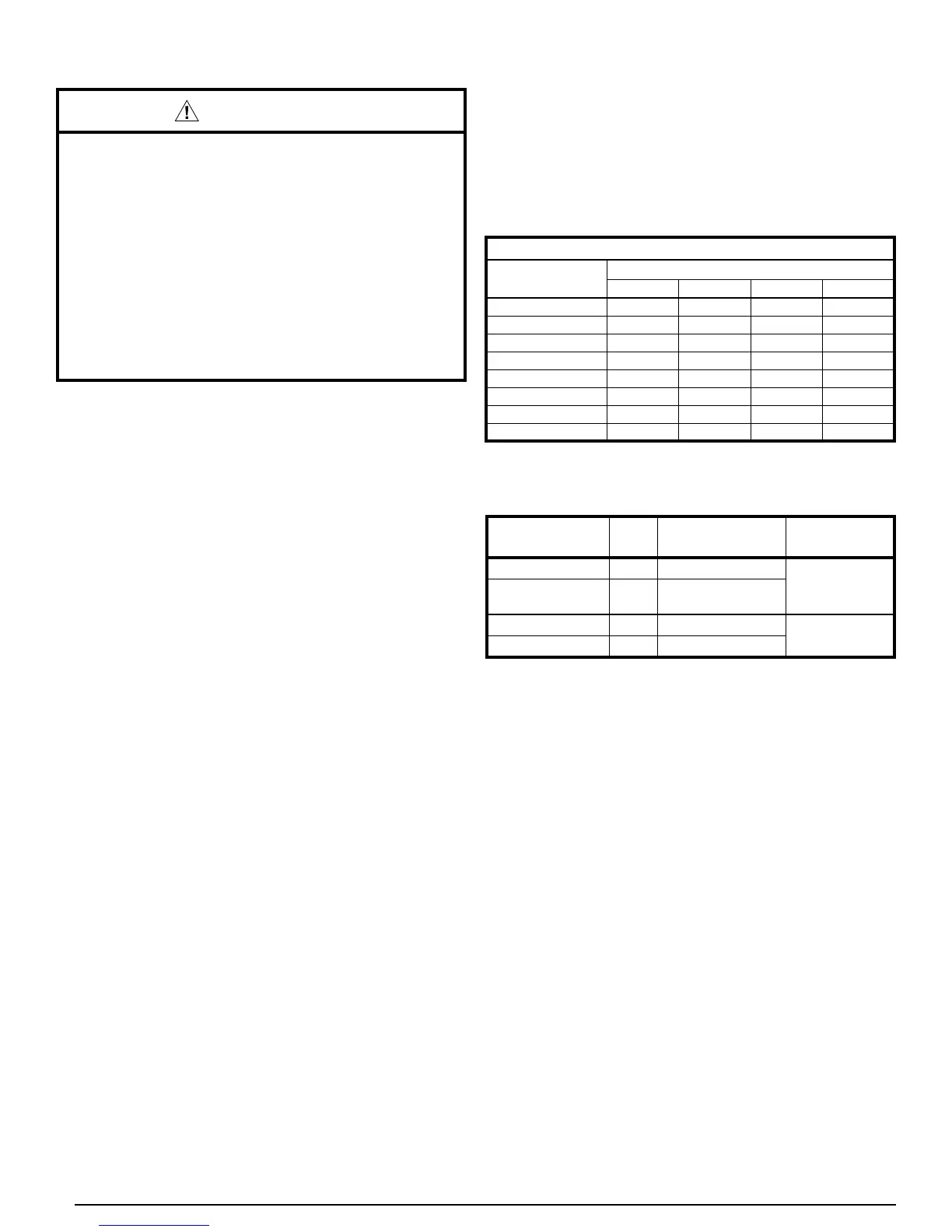

WIRE COLOR

ID FUNCTION

INDOOR

CONNECTION

RED

R

24VAC

FurnaceorAir

Handler

BLK

C

24 VAC common

or ground

YEL

Y1

1st Stage call

Thermostat

BLU

Y2

2nd Stage call

Table 2.

Loading...

Loading...