8

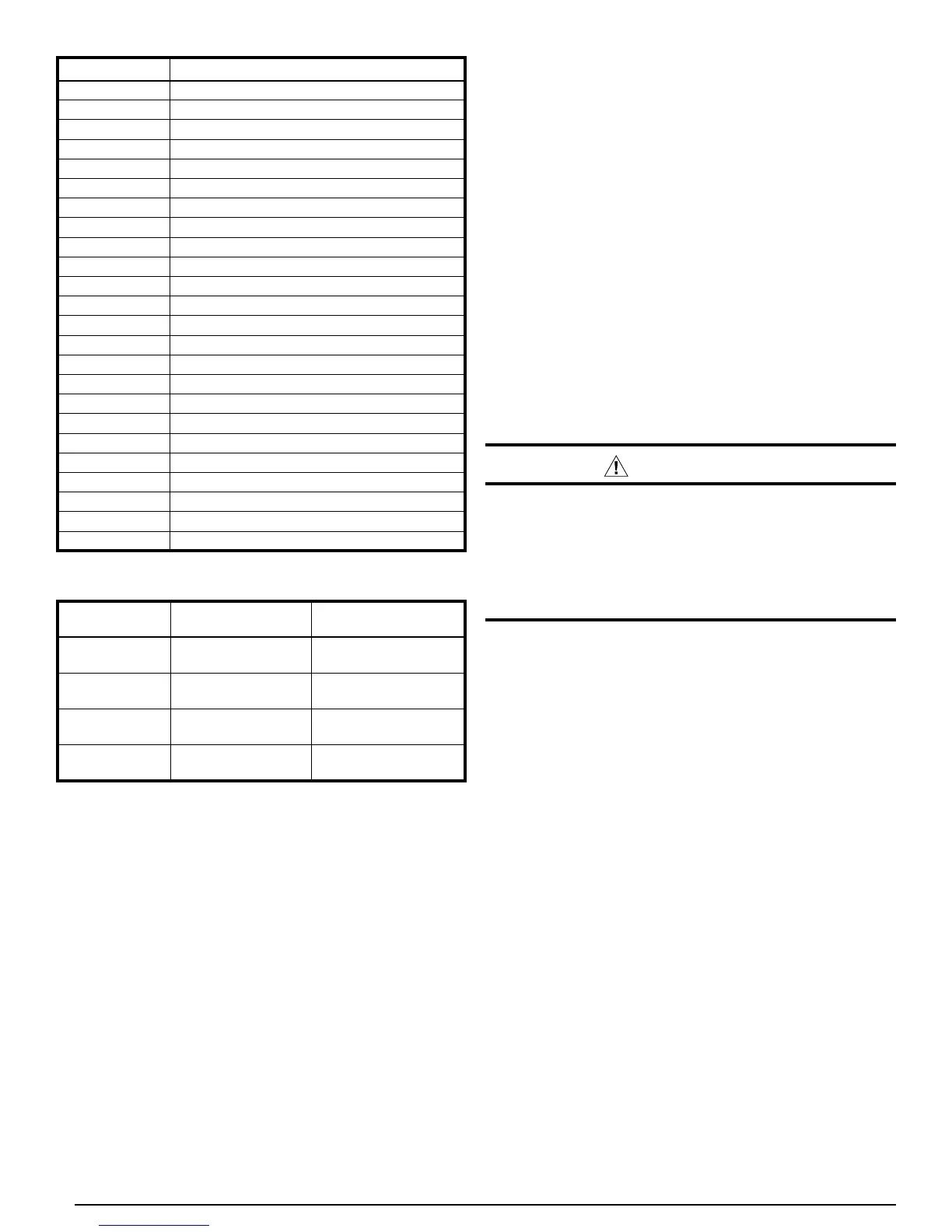

Table 7. Instrumentation List

FUNCTION TYPE CONNECTION

High Pressure

Switch

Opens650±15psig,

recloses460±15psig

See Figure8, and

Figure9

LowPressure

Switch

Opens20±5psig,

recloses35±5psig

IFB*LP1-LP2

Ambient

Air Temp

Thermistor10KΩ @

25°C(Fig.10)

IFB*“OUTDOORTEMP”

(BLK)

Compressor

Discharge Temp

Thermistor10KΩ @

25°C(Fig.10)

IFB*“DISCHARGETEMP”

(RED)

*IFB=InterfaceBoard

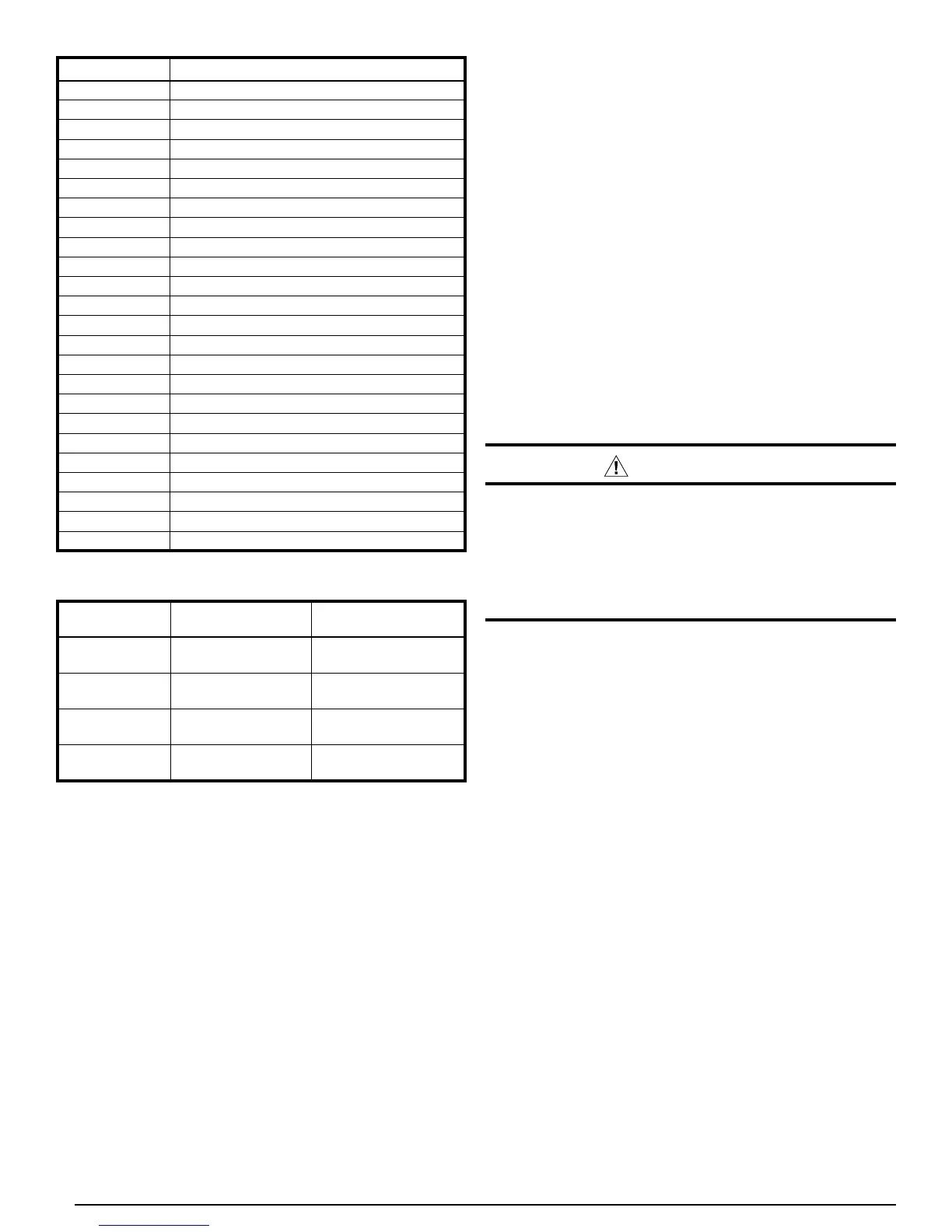

Table 6. Interface Board Diagnostic Codes

DISPLAY CAPACITY STAGE

1

Inverter Power Module Overcurrent

GeneralInverterDriveFault

High Compressor Current

4

Current Sampling Error (Inverter)

HighInverterHeatSinkTemperature

6

High DC Bus Voltage (Inverter)

7

LowDCBusVoltage(Inverter)

8

LowLineVoltageatInverter

9

LineOvercurrentatInverter

1

LineVoltageSamplingError(Inverter)

11

LossofCommunication(InverterInternal)

1

InverterHeatSinkSensorFailure

1

LossofCommunication(InverterInternal)

14

LossofCommunication(IFBtoInverter)

1

Override, High Compressor Current

16

Override,HighLineCurrent

17

Override,HighInverterHeatSinkTemp

18

OutdoorFanMotorFault

19

LowPressureSwitchOpen

High Compressor Discharge Temperature

1

Interface Board Software Error

SensorFailure-CompressorDischgTemp

4

SensorFailure-AmbientTemperature

9

CoolingLowTemperatureLockout

TROUBLESHOOTING

The2-characterLEDdisplayontheinvertercontrolboardis

intended to be helpful in diagnosing problems. Under normal

operation, the display will always show both a status indicator

(Table5) along with fault indications (Table 6).

The fault indications are a sequential listing of fault history.

The last 10 fault codes recorded are displayed in sequence,

with the most recent rst. If there is an“active” fault, one

which is currently detected and responsible for interrupting

operation, the right hand decimal point in the display will be

lit,andtherstnumberinthelistwilldouble-blinkatrst,then

appear again. If this decimal point is not lit, all codes listed

are historical only, and none are“active”. Also, if no code

numbers are displayed, there have been no faults recorded,

or the history has been cleared.

NOTE: As standard practice, write down the fault codes in the

history before attempting to clear the history. In troubleshooting,

focusonfaultcodesthatreturnas“active”afterthehistory

has been cleared. Do not replace hardware based on history

alone,i.e.,onfaultsthatarenot“active”.

WARNING:

Do not touch inverter conductors or the tops of

its large capacitors until power has been off for

at least 30 seconds. The inverter will retain a high

voltage for a time after power has been removed.

Failure to comply with this warning could result in

serious injury, death or property damage.

The list of past faults can be cleared by shorting the TEST

pins (J4) at the lower right side of the inverter control board

(when the unit is powered up but not running). This procedure

willalsoforcetheunittobypassthenormal5minutestop-

to-start delay.

Fault and warning codes are listed in Figure 6 (page 13)

and on a label affixed to the inside surface of the control

panel cover.

Inverter Circuit Board LEDs

Forsomeinverter-relatedfaultcodes,itishelpfultonoteat

leastwhetherornotLEDsarelitonthemaininvertercircuit

boards, which are mounted behind the interface board on

whichthecodesaredisplayed.For2,3,and4-tonmodels,

lookforalitLEDabout3inchesdirectlybehindthe2-character

display.Forthe5-tonmodellookforalitLEDabout3inches

directly behind the lower edge of the secondary contactor that

ismountedonthe leftsideoftheuppermounting bracket.

NOTE:ThereareotherLEDsontheinvertercircuitboards

as well as those described above.

FornormaloperationtheinverterLEDslocatedasdescribed

above will blink green slowly. When there is an inverter-

generatedfault,aredLEDnexttothegreenonewillash.

Normally this will be translated into a 2-digit fault code on the

main display.

If the green LED (described above) is not lit, it generally

indicates that line voltage is not getting to the inverter via the

contactor.Checkforthepresenceof208/230voltsbetween

the top two terminals of the main contactor. If voltage is

Loading...

Loading...