9

present, the inverter needs to be replaced, or internal wiring

isincorrect.Iflinevoltageisabsent,checkfor24vacacross

the main contactor coil, and verify line voltage between the

lower terminals of the contactor. If 24 volt coil voltage is absent,

checkcontinuitythroughthehighpressureswitch,andverify

that the COMMUNICATIONS PORT plug is in place at J6 at

the bottom edge right of the interface board.

No Control Board Display

If the 2-character display on the interface board shows nothing,

verify that 24 vac control voltage is present between R and C

(redandblackwiresoftheeldwiringharnesspluggedintothe

rightsideofthecontrolboard.Ifvoltageisabsent,checkeld

wiringbacktotheindoorunitandtransformerandthermostat.

Ifvoltageispresentbutthedisplayisblank,thecontrolboard

needstobereplaced.Checkwiringforindicationsofadirect

short before trying a new board.

Troubleshooting Individual Fault Codes (when

FollowtherecommendedtroubleshootingproceduresinTable

8for“active”faults.Insomecasesmorethanonefaultcode

or different active codes may be generated by one issue, e.g.

interruption of line power. Always cycle line power (30 seconds

off, then on for at least 1 minute) to confirm that an active fault

returns, is re-declared, before considering replacing hardware.

Most inverter-related faults are at least temporarily cleared by

cycling power in this manner. Do not replace hardware based

onhistoryalone,onfaultsthatarenot“active”.

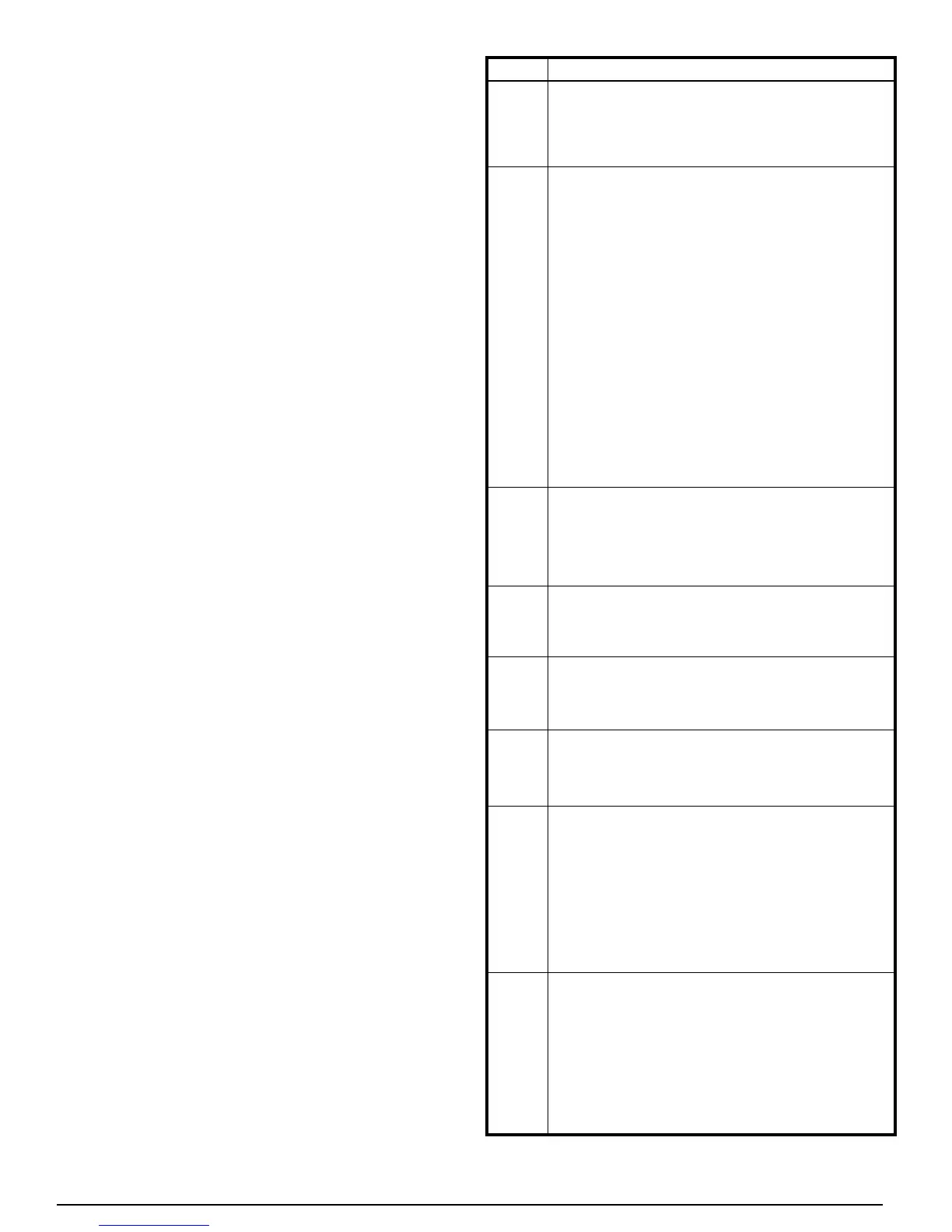

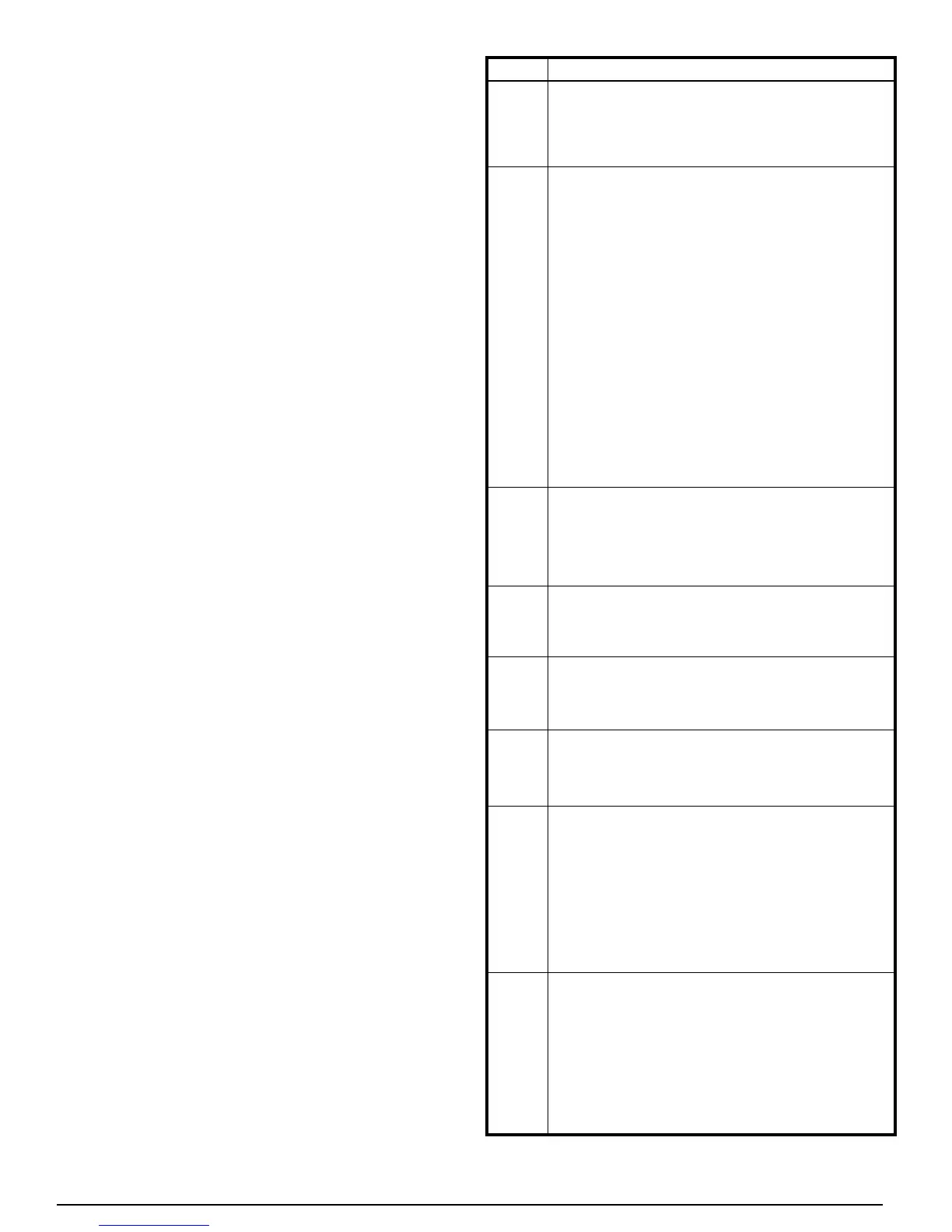

Table 8. Individual Fault Codes

CODES DESCRIPTION

1

9

These codes indicate abnormal high current or high

inverter temperature. If they persist and return as active

fault codes, they may indicate a faulty inverter drive or a

wrong interface board/inverter combination.

Compressor Drive Failure – This generally indicates

a compressor problem which may be temporary or

permanent. If the compressor has just been replaced,

recheck the U, V, and W compressor leads for a

connection mistake.Before the inverter declares this

fault during an attempted startup, it will try to start the

compressor 4 times, with approximately 20 seconds

pause between attempts. During start attempts, listen

for compressor noise; if none, the compressor may need

to be replaced. Check compressor phase-to-phase

resistances; they should all be less than 1.5 ohms

and within 0.2 Ω of each other. If compressor noise is

loud, squealing, or otherwise unusual, the compressor

may need to be replaced. If the compressor restarts

normally, this fault code may be simply an indication that

the compressor speed has been temporarily disrupted

by either starting or shutting down abruptly against a

high pressure ratio. In either case, the system may

be normal but only temporarily affected by abnormal

running conditions.

4

1

11

1

1

These fault codes refer to internal inverter operation and

arelikelytoindicateinverterfailure.Iftheypersistand

return as active fault codes, replace the inverter assembly.

6

– This is an indication that line

voltage exceeded 10% over nominal value. The cause

is likely to be power grid abnormalities or a poorly

controlled generator.

7

– In most cases this is an

indication that 208/230 volt line power was interrupted

or disconnected. It may also indicate low line voltage

or, rarely, an internal inverter failure.

8

– This indicates that line voltage

hasdroppedbelowapproximately170volts.Itmayalso

indicate loss of line power, in which case Code 7 may

appear in addition to or instead of this code.

14

Loss of Communication Between Inverter and

Interface Board – Check the inverter LEDs (as

described in Inverter Circuit Board LEDs section) for

anindicationthattheinverterhaslinepower.Followthe

troubleshooting steps described in that section first. If

theinverterLEDsarelitbutthecodeisactive,verifythat

the 4-pin plug at J5 ) is connected at

the bottom edge center of the interface board. If these

checksdonotresolvethefault and thefaultremains

active, replace the interface board.

1

16

17

These are warning codes that simply indicate that a

high current or temperature condition was reached,

andthattheinverterwasabletokeeptheparameterin

an acceptable range by automatically reducing speed.

These conditions do not result in the unit shutting down

(unless the current or temperature increased further

and reached a shutdown limit, in which case another

code would be displayed). NOTE: If a high current or

temperature shutdown occurs, these warning codes are

not necessarily displayed and stored.

Loading...

Loading...