5

The maximum vertical elevation between the air conditioner

andindoorcoilis50ft.Systemsthatrequiremoreelevation

will need to have an oil trap installed in the vapor line. Refer to

theApplicationGuidelineforRefrigerantLinesOver75Feet

(document 044B-0600) for piping details.

A filter drier is supplied with the air conditioner. It is required

and recommended that it be installed near the indoor coil.

It is recommended to replace existing refrigerant lines that

were previously used for an R-22 system. If the lines are not

replaced, they must be properly flushed by a licensed EPA

certied technician in accordance with the manufacturer’s

instructions and established procedures.

ofvacuum.Lossofvacuumindicatesthatthereisaleakin

thesystem.Repeattheleaktestifrequired.

3.Evacuatethe system to at least 500microns to remove

non-condensables and water vapor. Close the manifold

valves and remove the vacuum pump.

4.Connecttherefrigeranttanktothecentermanifoldportof

thegaugeset.Pressurizethesystemenoughtobreakthe

vacuum.

5.Openbothservicevalvesbyturningthevalvestems¼turn

counterclockwise.Thestemwillbeinlinewiththetubes.

Replace the stem caps and tighten. Proceed with Refrigerant

Charging section.

WARNING:

The air conditioning system contains liquid and

gaseous refrigerant under pressure. Adjustment of

refrigerant charge should only be done by a qualified,

EPA certified technician thoroughly familiar with this

type of equipment. Under no circumstances should

the homeowner attempt to install and/or service this

equipment. Failure to comply with this warning could

result in equipment damage, personal injury, or death.

Refrigerant Charging

NOTES:

• Theunitmustbechargedataxedspeedsetting.Forthis

purpose the thermostat needs to be wired and powered

prior to charging.

• The air conditioner is factory charged for eld installed

lines15ft.inlengthwiththematchingindoorequipment.

Adjustments to the refrigerant charge will be required for

otherlengthandtubesizes.Forlineslongerthan15ftwith

a3/8”ODliquidline,add0.52oz.perft.SeeTable 4 (page

5).

• Smallvariationsinthe temperaturesand pressuresare

normal due to differences in the installation.

• Large variations in the temperatures and pressures

could indicate incorrect charge or another problem with a

component in the system.

The preferred method of charging is by weighing in the

additional refrigerant required. If a charging scale is not

available, the next preferred charging method would be to

use the sub-cooling method. After weighing in extra charge,

the subcooling values should be measured to confirm proper

charge.

Brazing

Use the appropriate safety equipment while brazing. Items

such as gloves, safety glasses, proper ventilation, and a fire

extinguisher should be used.

1. Route the refrigerant lines from the indoor coil to the service

valves on the air conditioner. Avoid sharp radius bends and

turns. See Figure5(page12)

2.Makesurethatthevaporlineisproperlyinsulatedforthe

entire length of the run for maximum system efficiency.

Improper insulation may also create condensation and result

in water damage to the equipment and building structure.

3. Remove the valve cores from the air conditioner service

valves. Wrap the valves completely with wet rags to protect

them from overheating during the brazing operation.

4. Connect both the vapor and liquid lines. Tubes should be

round, de-burred and free of debris. Use a phosphorous

and copper or silver brazing alloy for the joints. Do not use

soft solder with a low melting point.

5.Connect the indoor lines according to the indoor unit

instructions. The indoor coil will require the same alloys and

wet rags to protect the sensors from excessive heat on the

refrigerant lines.

6. Allow the service valves to cool and replace the valve cores.

7.Leaktesttheconnectionsusinglowpressuredrynitrogen.

System Evacuation

1. Connect the refrigerant gauge manifold to both the vapor

and liquid service valves. Figure5. Connect the center port

to the vacuum pump.

2. Open both manifold valves and start the vacuum pump.

After a short time, it is recommended to close the manifold

valvesandstopthevacuumpumptolookforarapidloss

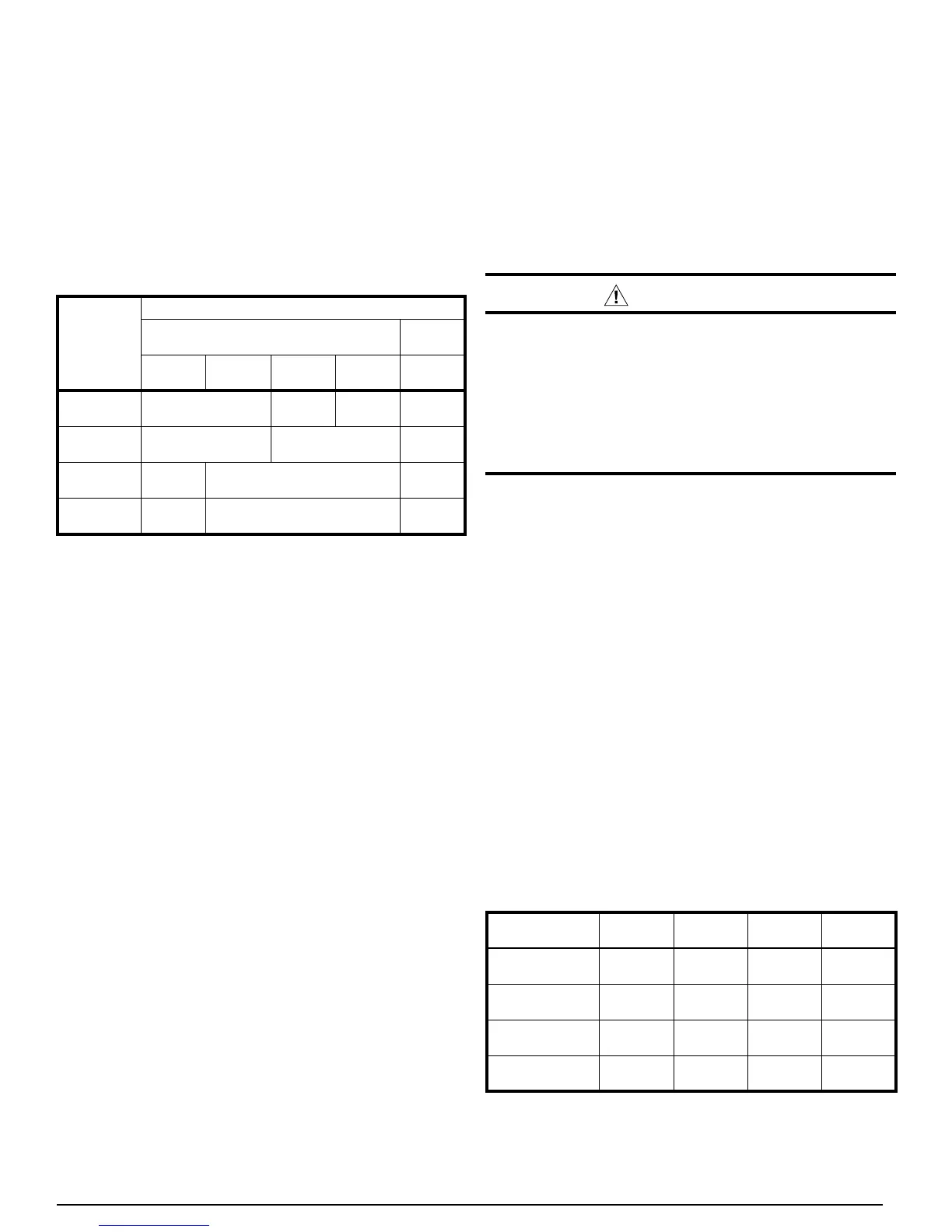

MODEL

LINE SET LENGTHS

LIQUID

LINE

UP TO

24 FT.

25 TO

39 FT.

40 TO

75 FT.

75 TO

100 FT.

UP TO

100 FT.

-024K Units

3/4 in.

(19 mm)

7/8in.

(22 mm)

1 1/8 in.

(29 mm)

3/8 in.

(10 mm)

-036K Units

7/8in.

(22 mm)

1 1/8 in.

(29 mm)

3/8 in.

(10 mm)

-048K Units

7/8in.

(22 mm)

1 1/8 in.

(29 mm)

3/8 in.

(10 mm)

-060K Units

7/8in.

(22 mm)

1 1/8 in.

(29 mm)

3/8 in.

(10 mm)

Table 3. Permissible Refrigerant Line Sizes

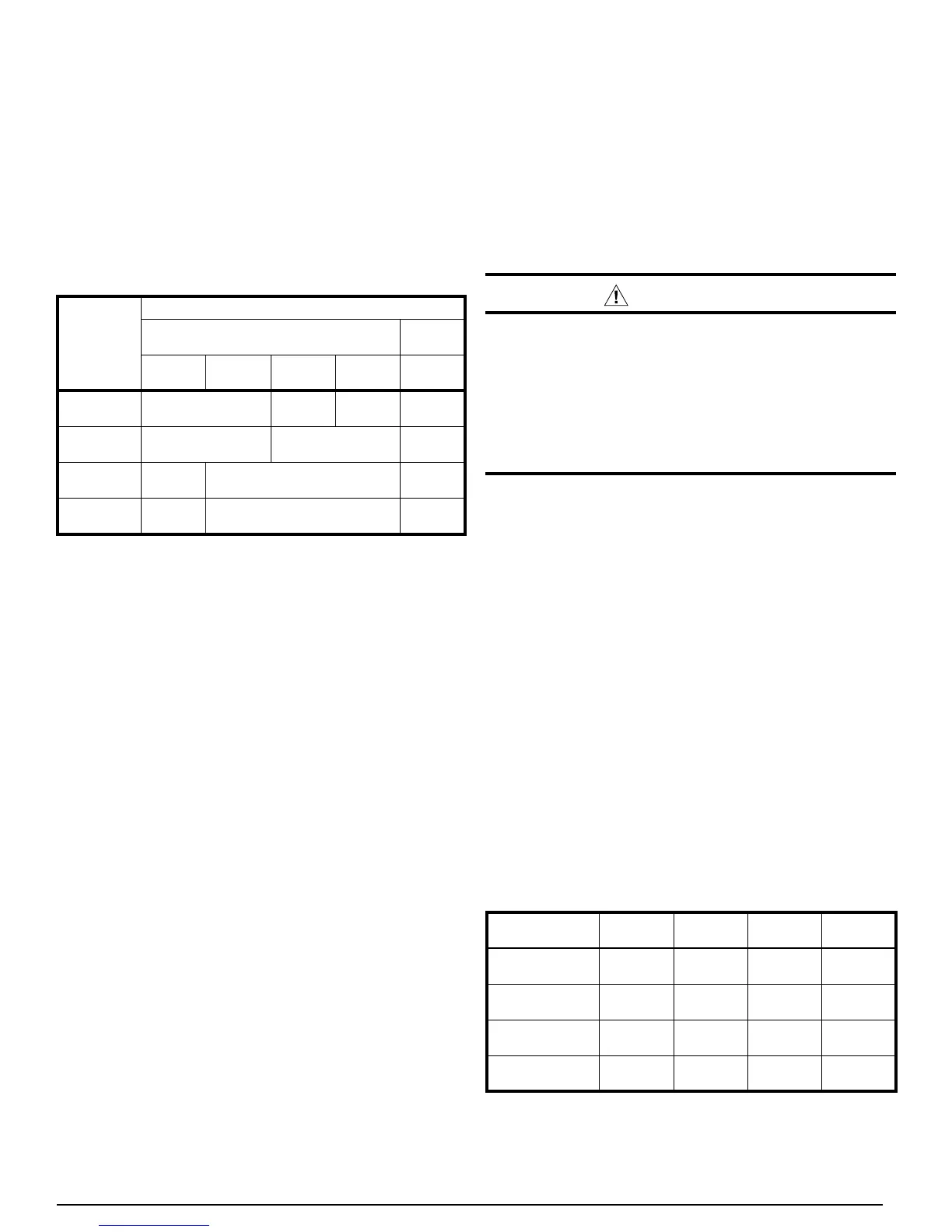

MODEL

2 TON

3 TON

4 TON

5 TON

FactoryCharge

for15ft.lineset

78oz 93 oz 110 oz 123 oz

Additional Charge

for 40 ft. line set

16 oz 16 oz 18 oz 18 oz

Additional Charge

for75ft.lineset

39 oz 43 oz 44 oz 44 oz

Additional Charge

for 100 ft. line set

57oz 62 oz 63 oz 63 oz

Table 4. Refrigerant Charge Quantities

Loading...

Loading...