OM 200MICRO 29

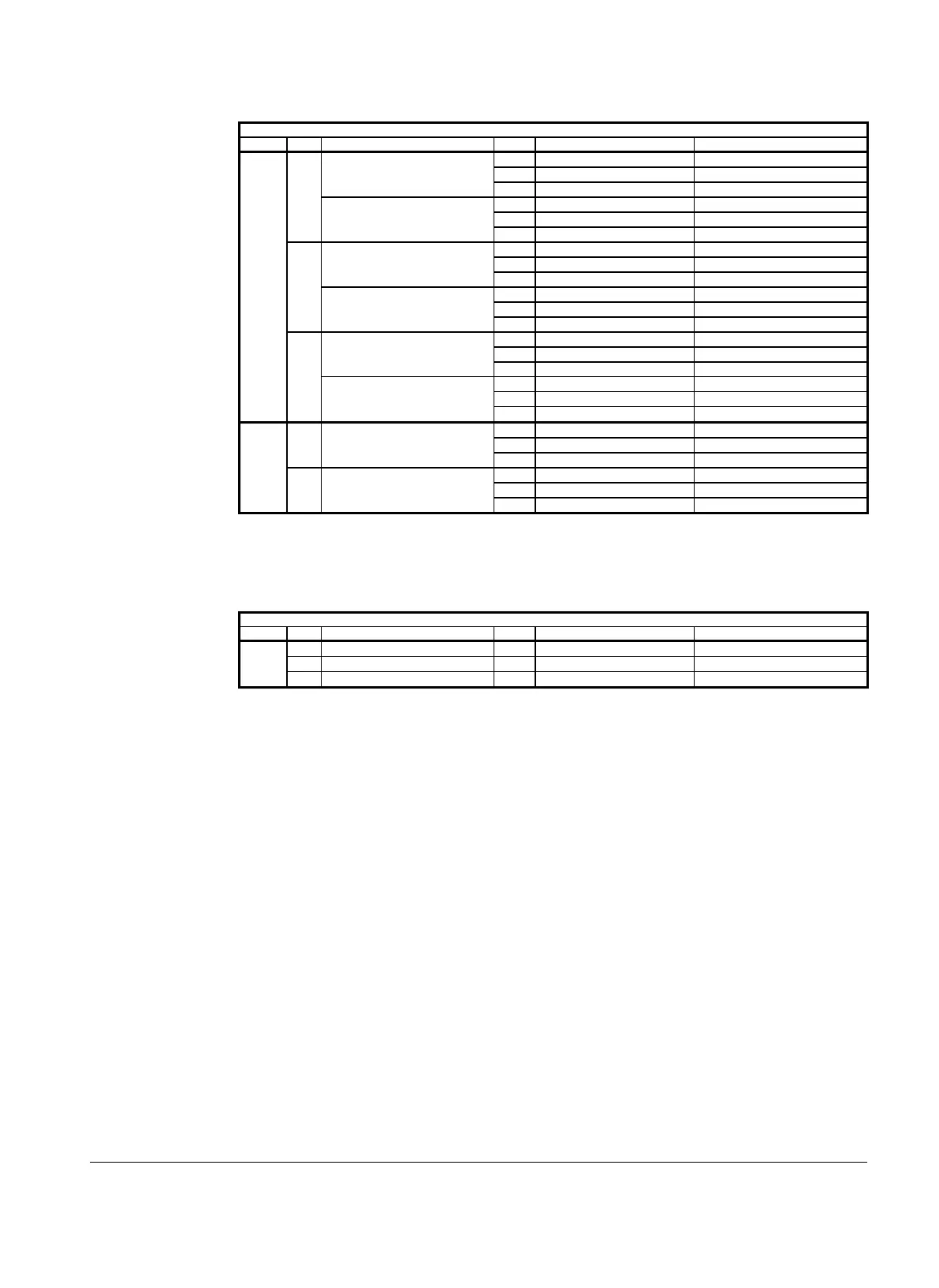

Table 16 Continued

Item

Screen Line Display Field Range Extended Name

1 Jan-Dec Holiday Month

2 00-31 Holiday Date#7=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date

1

#10=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date#8=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date

2

#11=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date#9=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date

2

3

#12=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date1 #13=N/A-00 00 Day(s)

3 00-31 Duration Days

1 Jan-Dec Holiday Month

2 00-31 Holiday Date

3

2 #14=N/A-00 00 Day(s)

3 00-31 Duration Days

Press the "NEXT MENU" key and menu 17 (Timers) will be displayed. Menu 17 has one screen. This

menu is password protected and requires the operator password.

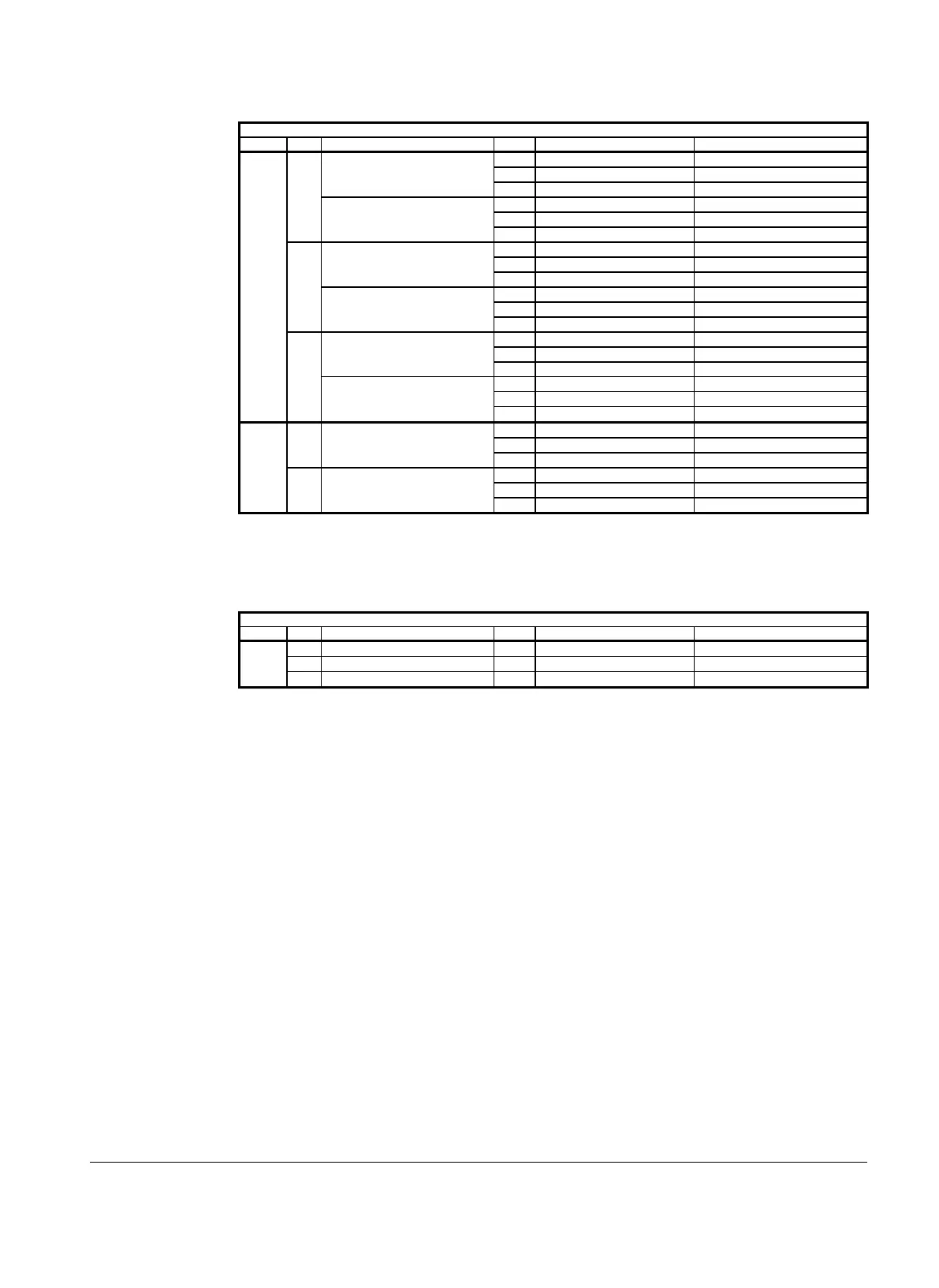

Menu 17, Timers

Item

Screen Line Display Field Range Extended Name

1 Start-Start=15Min 1 15-60 Min Start to Start Delay Timer

2 Evap Recirc=15Sec 1 15 Sec-5 Min Chilled Water Recirculation Timer1

3 Stop-Start=3Min 1 3-20 Min Stop to Start Delay Timer

Start-Start= This value determines the minimum time between chiller starts. The chiller must run the

time selected before it will start again. If the chiller runs less that the time selected the timer will have

to time out before another start is allowed. This is to eliminate chiller cycling that could damage the

motor by starting to frequently.

Evap Recirc= This value determines the time the chilled water pump must run before the start

sequence is started. This value insures that the chilled water system has an adequate load to start the

chiller. It also insures that the chilled water pump has time to establish constant flow in the system to

prevent nuisance water flow switch trips.

Stop-Start= This value is similar to the Start-Start already described. This time insures that there is

adequate time between stop to start for the chiller to become stable or pressures to equalize. This can

also be used to minimize short cycling.

Press the "NEXT MENU" key and menu 18 (Pump Set Points) will be displayed. Menu 18 has one

screen. This menu is password protected and requires the operator password.

Loading...

Loading...