www.megger.com

OTS80PB and OTS60PB OTS100AF, OTS80AF and OTS60AF

16

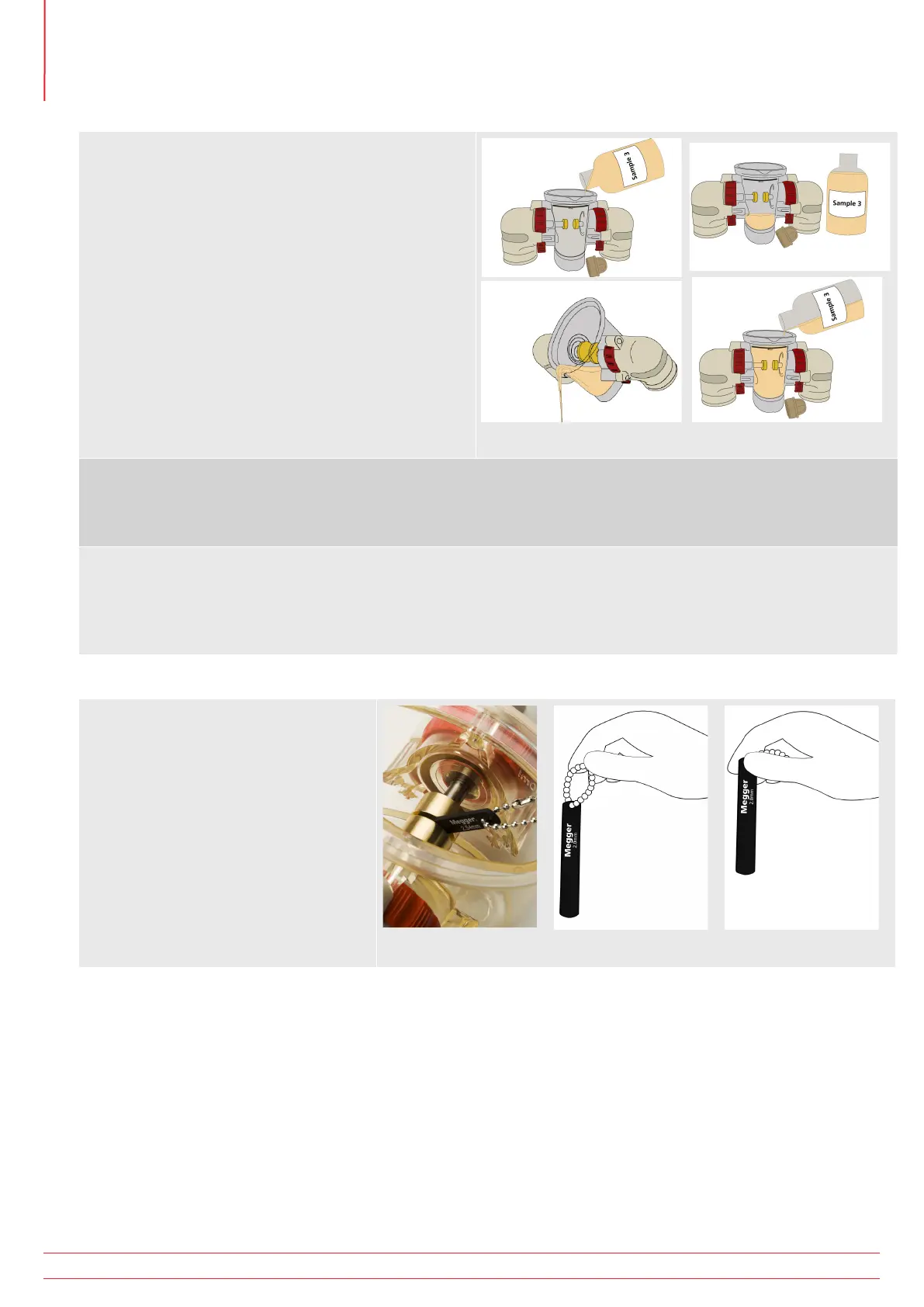

Preparations for use

Immediately prior to testing, vessels stored full of oil

must be drained and all internal surfaces, including the

electrodes, rinsed with fluid taken from the sample to

be tested.

The vessel should then be drained again. Swiftly and

carefully fill with the test sample, taking particular care

to avoid the formation of bubbles. If the vessel was

stored empty, or if it is to be used for a different type of

fluid from that with which it was filled during storage,

it should be cleaned with an appropriate solvent before

rinsing and filling.

1 2

3 4

Fig 3: Preparing the vessel

ASTM D1816 specifies the use of a dry hydrocarbon solvent such as kerosene, which meets the requirements of D235.

Solvents commonly used include acetone and, in the USA, toluene. Toluene is banned in Europe.

Solvents with a low boiling point should not be used as these evaporate rapidly, cooling the vessel and giving rise to the

risk of condensation.

Use lint-free clean-room wipes to clean the vessel. Do not use paper towels as they may introduce particles that hold

moisture, causing breakdown values to be dramatically reduced.

Touching the electrodes or the inside of the vessel should be avoided and during cleaning, the electrodes should be

checked for pitting or scratches that may cause breakdown voltage values to be decreased. Remember that the rules of

cleaning apply to all parts that will come in contact with the oil sample during testing.

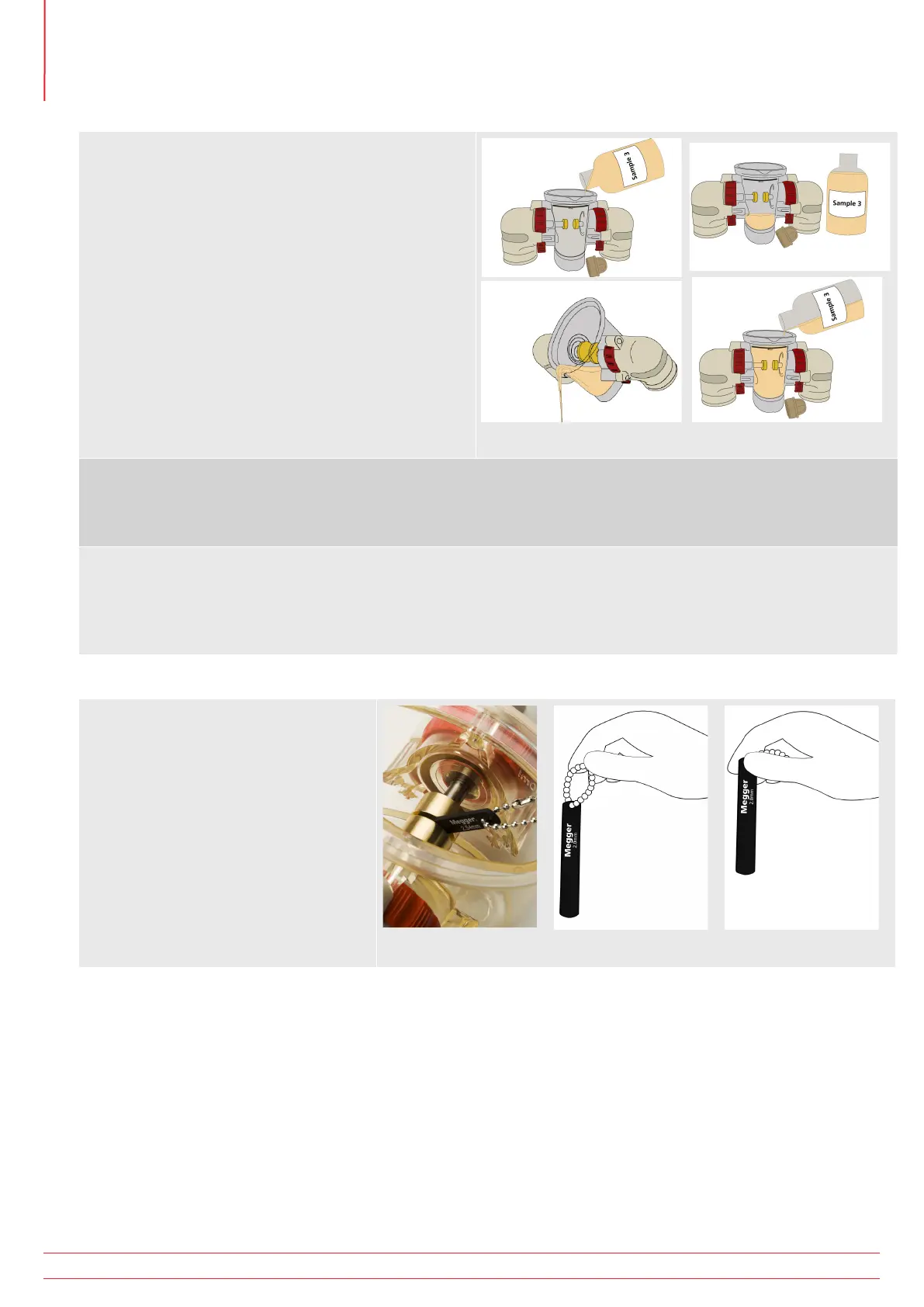

Setting the electrode gap

Setting the electrode gap accurately is

very important; the results obtained are

only valid if the gap is correct. A big

problem is movement of the electrodes

after the gap has been set and for

this reason, many users of oil test sets

check the electrode gap frequently –

sometimes before every test. A better

solution is to use test sets where the

electrodes can be locked in position,

such as the instruments in Megger’s

latest OTS range.

✓

✖

Fig 4: Megger electrode gap gauge

Megger recommends the use of flat, smooth gap gauges. The latest Megger gauges have a black anodized coating,

which not only provides a smooth surface but also shows when the gauge is worn, as the shiny aluminium starts to

show through the coating.

When setting the electrode gap using the Megger gauge - See Figure 4

Ensure the gap is set in an empty vessel and before pouring in the sample to be tested to avoid contaminating the

sample with the gap setting process.

Hold the gap gauge with the key chain and place between the electrodes. This enables better view of the gap

gauge and prevents the gauge being forced into the existing electrode gap.

Carefully adjust the electrode gap without over tightening. The gap gauge should just be able to slide between the

electrodes with little force required to move it, while it is held from the chain. If force is required over tightening has

resulted and the electrodes must be adjusted to release this and rechecked ensuring that only a light force is needed

to move the gauge.

Loading...

Loading...