www.megger.com

OTS80PB and OTS60PB OTS100AF, OTS80AF and OTS60AF

17

Preparations for use

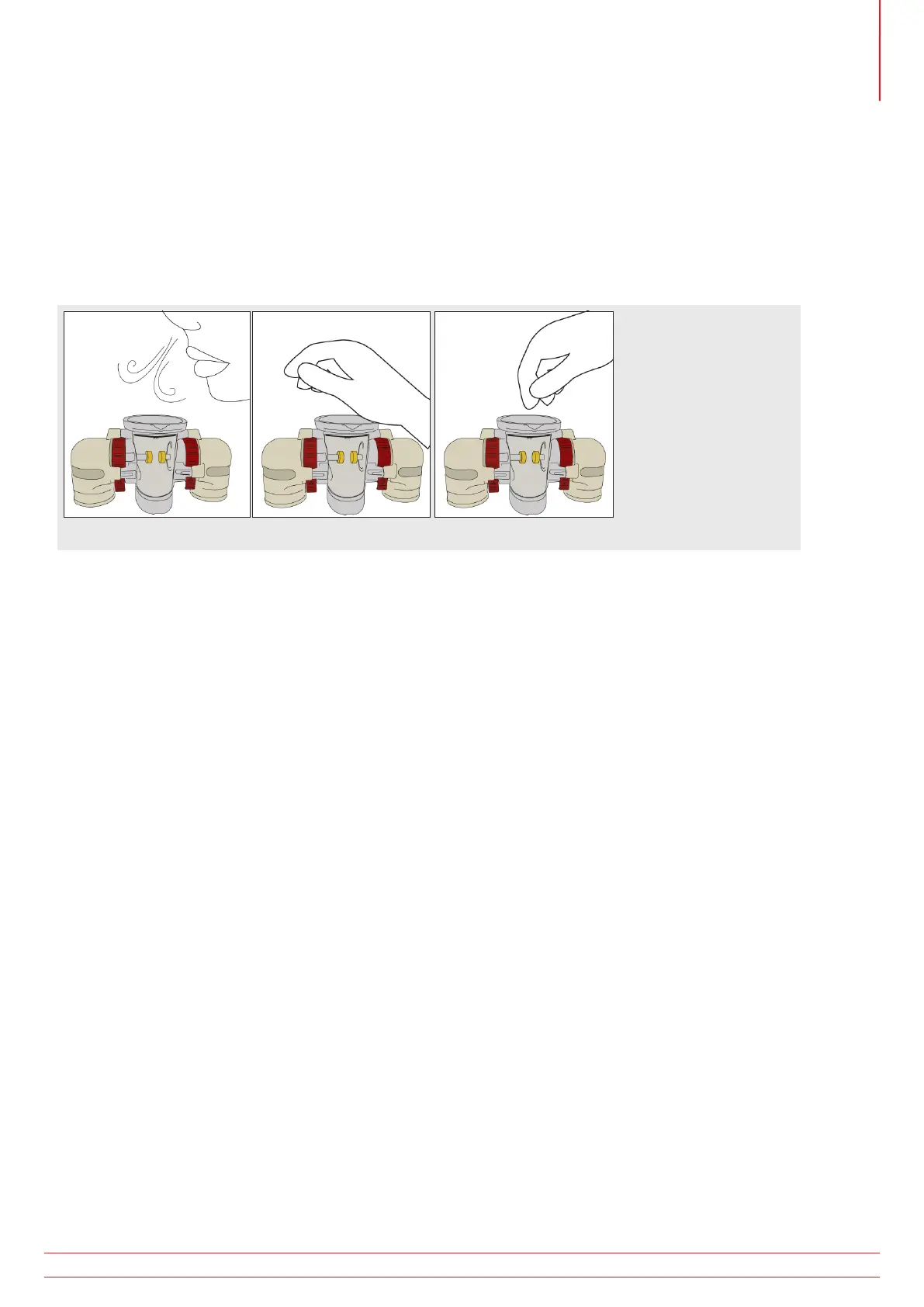

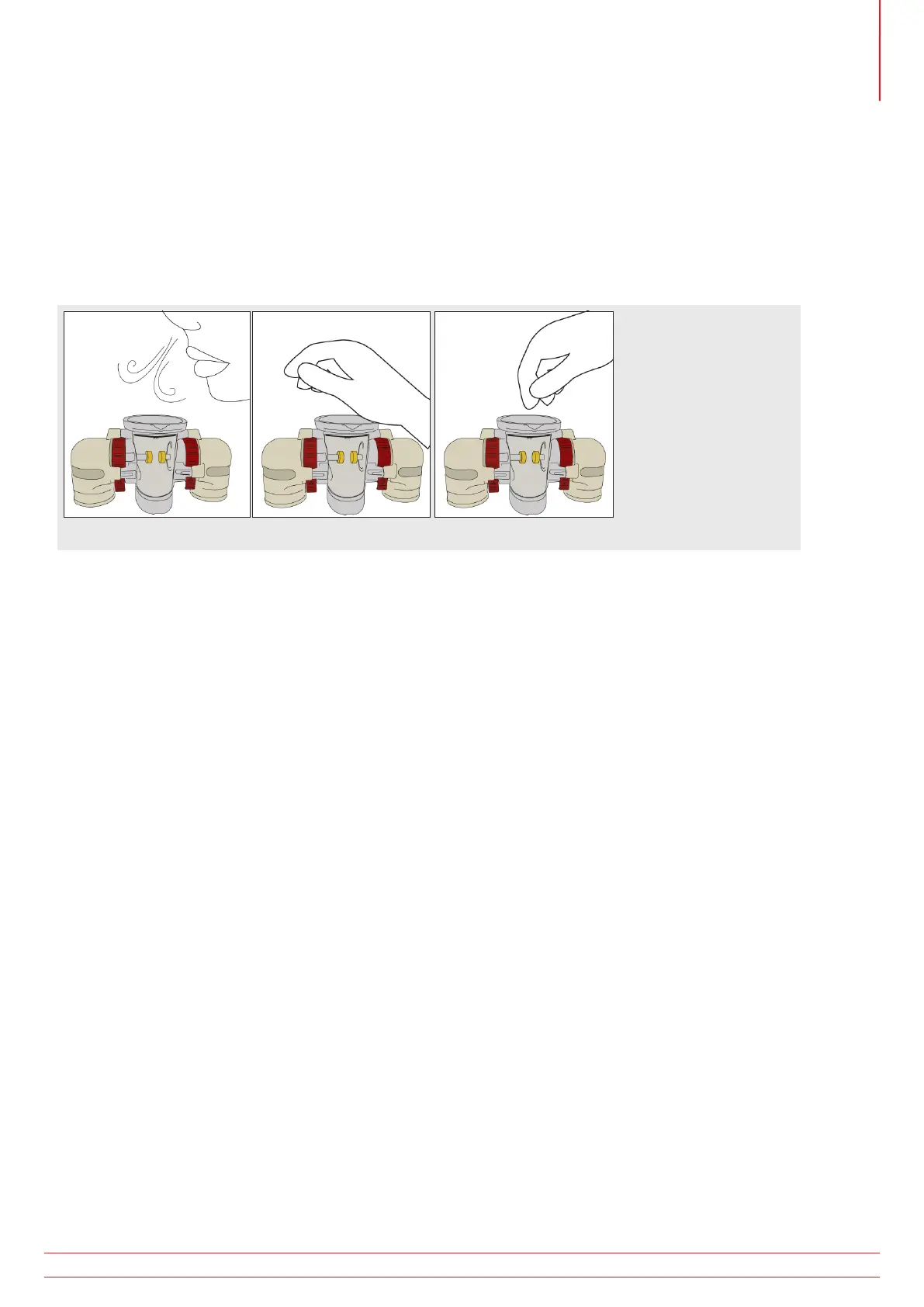

Finally remove the gap gauge. This should continue to move with barely a detectable drag between the

electrodes.

When setting the electrode gap, it is very important that the gap gauge barely touches the electrodes, with only the

slightest drag as it passes between them when held vertically in such a way as to minimise friction. Any significant

pressure could result in the electrodes springing towards each other after the gauge has been removed. Do not

breathe on the vessel when doing this to avoid moisture contamination, or lean on its rim or other parts to avoid

mechanical distortion.

✖

✖

✓

Fig 5: Do not breathe on the vessel or lean on its rim or other parts

Note: If the OTS is moved for one location to another please ensure the electrode gap is re-checked as described

above as a precaution.

Rinsing and then immediately filling the test vessel with the insulating fluid sample

Prior to filling the test vessel it is important to rinse the vessel with clean dry oil or with some of the sample oil about

to be tested. Rinsing should always be performed before each test, even if performing repetitive testing in an oil test

laboratory.

Remember that when rinsing the vessel, equal attention should be given to any magnetic bead, impeller, baffle plate,

lid and to the electrodes, not just the vessel walls. Rinsing should be applied to any surfaces that will come in contact

with the oil sample during testing.

After rinsing the test vessel with the sample oil it is most important to ensure it is immediately filled with the oil

sample to be tested. Any significant delay, (even a few minutes), may result in the oil film on the vessel’s walls

absorbing water from the air; since the walls have a large surface area, this is likely to contaminate the oil sample and

reduce the breakdown voltage once it has been mixed with the sample. Just 30 parts per million, (ppm), of water is

sufficient to halve the breakdown values.

In fact, ASTM D1816 specifies that the test vessel must be filled with the oil sample within just 30 seconds of the

rinsing taking place.

When filling, pour the oil sample into the vessel swiftly but with minimum turbulence so as not to entrap air.

Place the lid on the oil vessel, this will prevent contamination, then allow the sample to stand for a few minutes

before testing. Leaving the oil to stand will allow any air bubbles to clear from the oil.

However it is important not to leave the sample to stand for longer than absolutely necessary as it may absorb

water from the air in the headspace above it, again reducing the breakdown voltage. The baffle/lid must be fitted to

prevent air contact whilst the oil is left to stand to allow any bubbles to clear.

Loading...

Loading...