48

MAINTENANCE

6

7

a

b

c

e

d

f

9-10

8

a

c

b

d

e

f

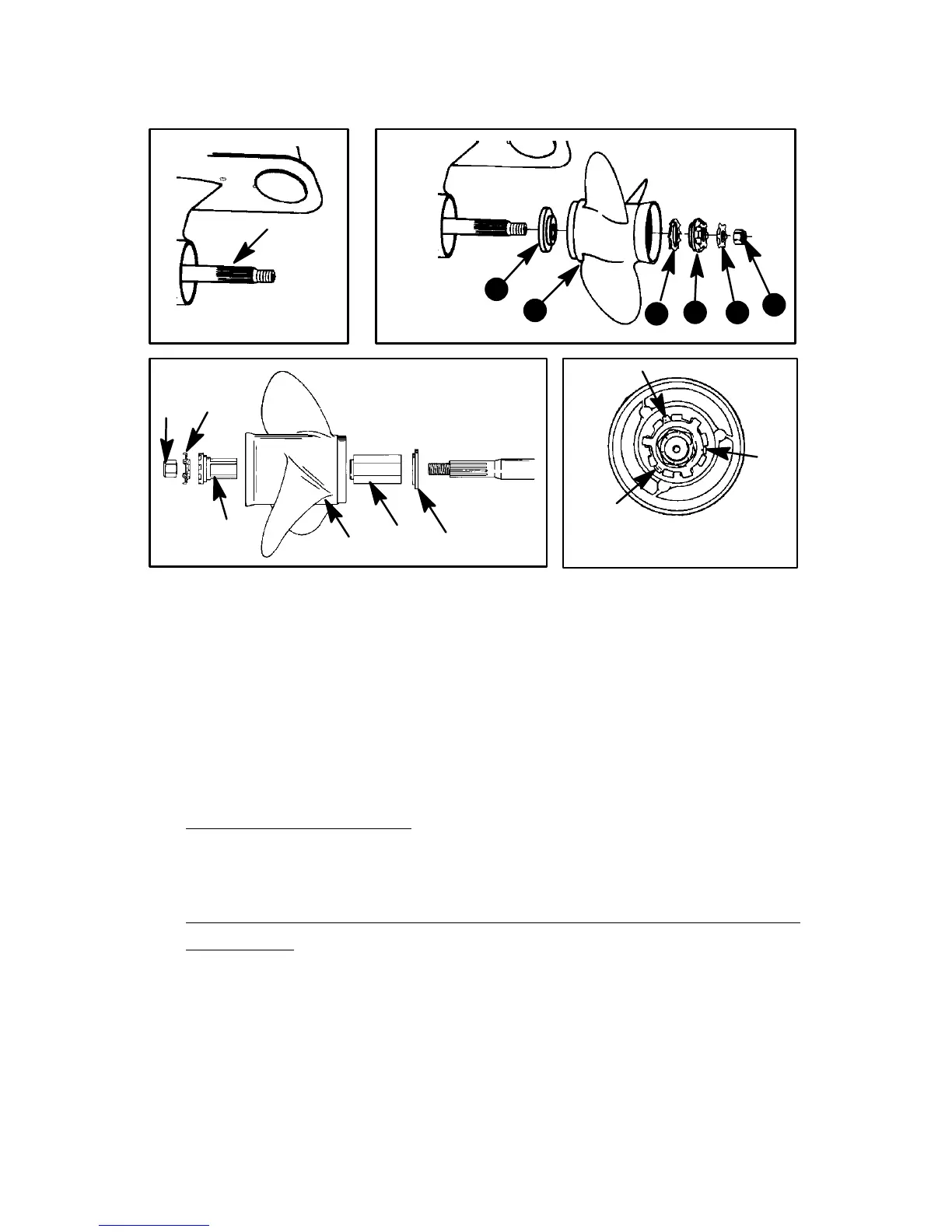

Propeller Replacement (Cont.)

6

Coat the propeller shaft with Quicksilver Anti-Corrosion Grease.

IMPORTANT: To prevent the propeller hub from corroding and

seizing to the propeller shaft, especially in salt water, always ap-

ply a coat of Quicksilver Anti-Corrosion Grease to the entire

shaft at the recommended maintenance intervals and also each

time the propeller is removed.

7 Rubber Hub Propellers - Install thrust washer (a), propeller (b),

continuity washer (c), splined washer (d), propeller nut retainer

(e), and propeller nut (f) onto the shaft.

8 Replaceable Hub Propellers (Using Hi-Performance Hub Kit P/N

835258A1) - Install forward thrust hub (a), replaceable drive

sleeve (b), propeller (c), drive sleeve adaptor (d), propeller nut re-

tainer (e) and propeller nut (f) onto the shaft.

9 Place a block of wood between gear case and propeller and

torque propeller nut to 55 lb. ft. (75 N·m).

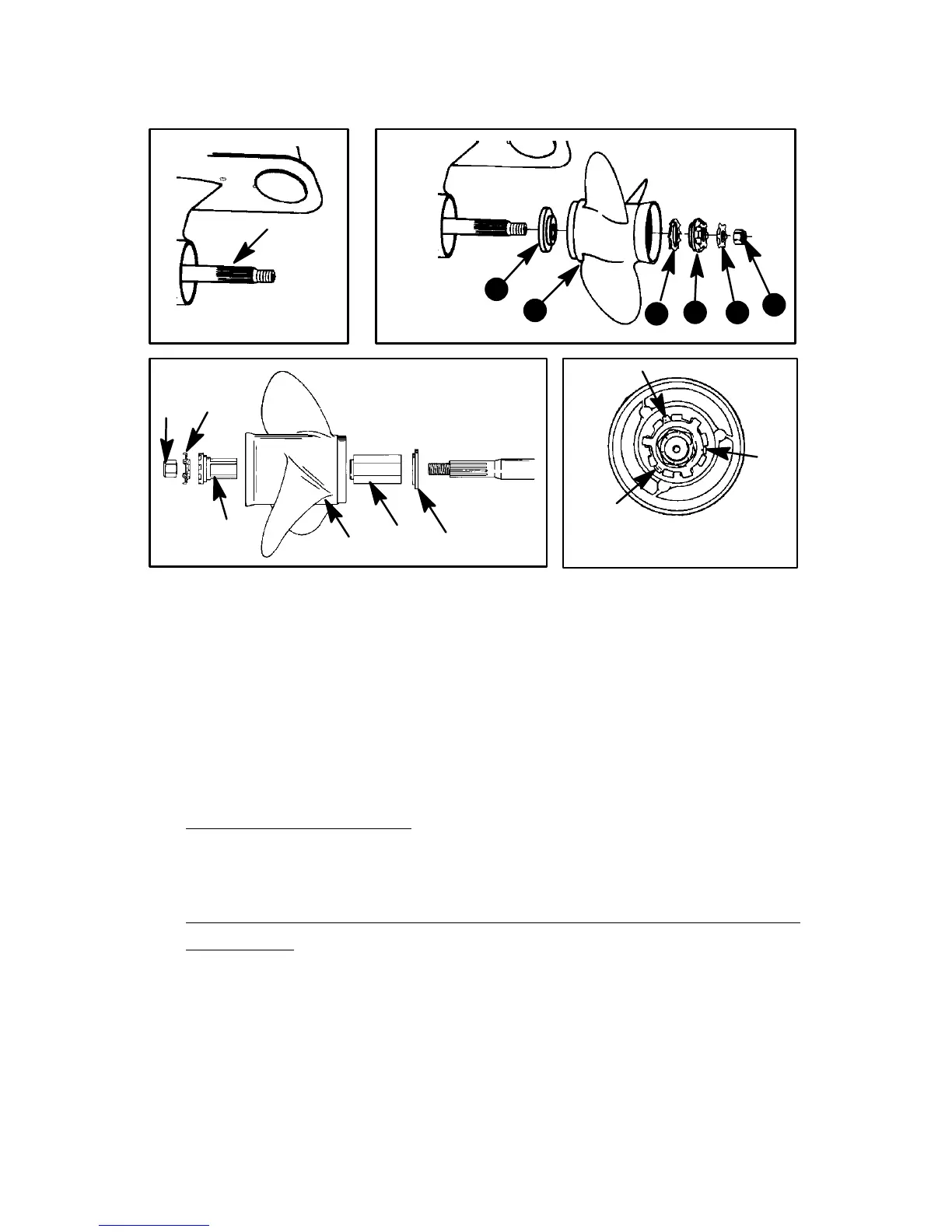

10 Secure propeller nut by bending three of the tabs into the thrust

hub grooves.

Loading...

Loading...