14

ii. Calculating Corrosion Rate

As explained previously, ER probes and instruments report Metal Loss. However, the value that is of

ultimate interest is Corrosion Rate. The Corrosion Rate is essentially Metal Loss over time, so the

Corrosion Rate can be calculated using the following formula:

Corrosion Rate(mpy) =

Loop Current(mA)

16

×

365

Time(days)

× Probe Life(mils)

where:

∆

Loop Current(mA) is the difference between two readings

∆

Time(days) is the time difference between those two readings

It is a common practice to program this formula into the control (DCS/SCADA) system and have it

calculate Corrosion Rate on a continual basis from the Metal Loss data. The challenge in doing this is

selecting an appropriate time interval. Using an interval that is too short may give erratic results,

while selecting an interval that is too long may give results that are insensitive to system upsets. The

ideal time period depends on many factors, and will vary from system to system. It may take some

trial and error to settle on the best time period for your installation.

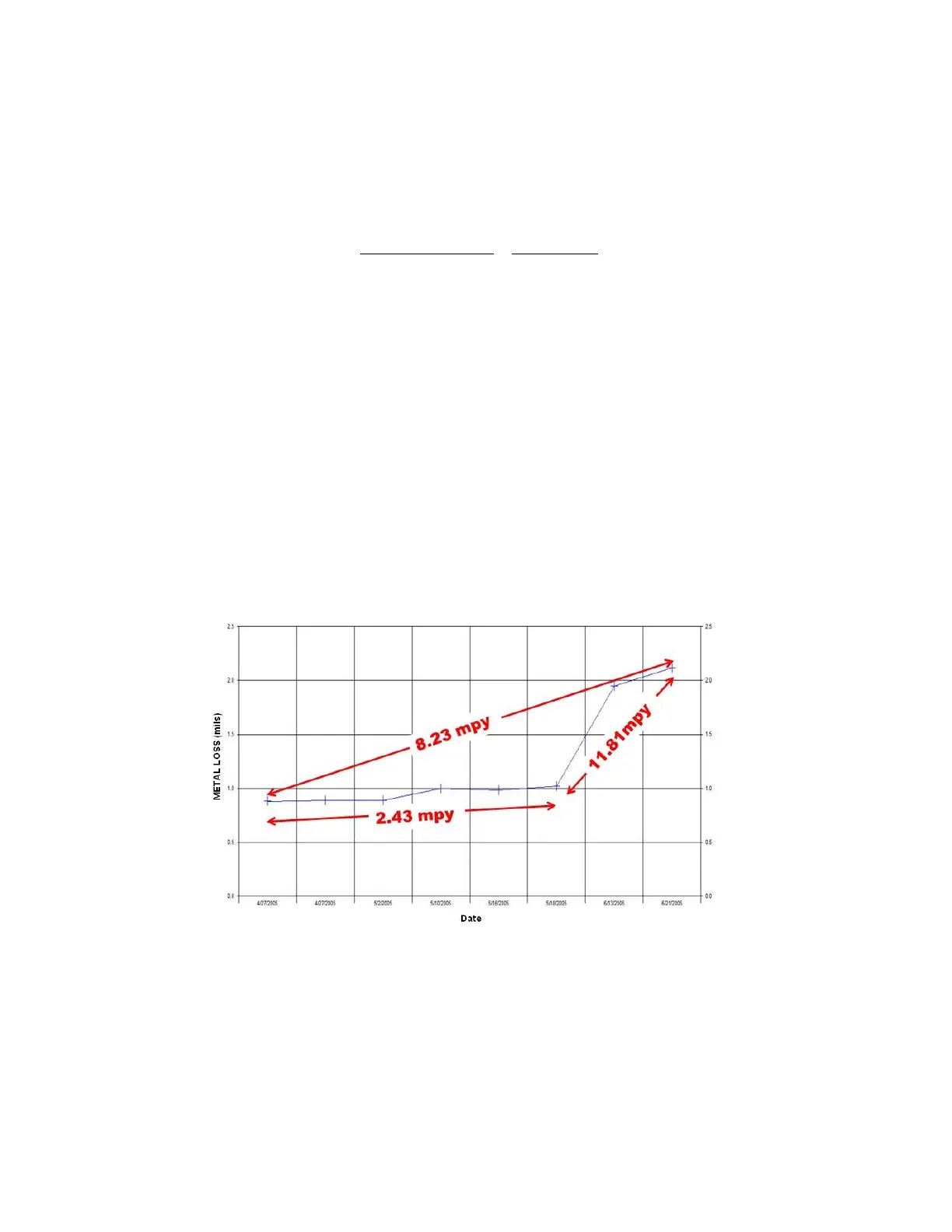

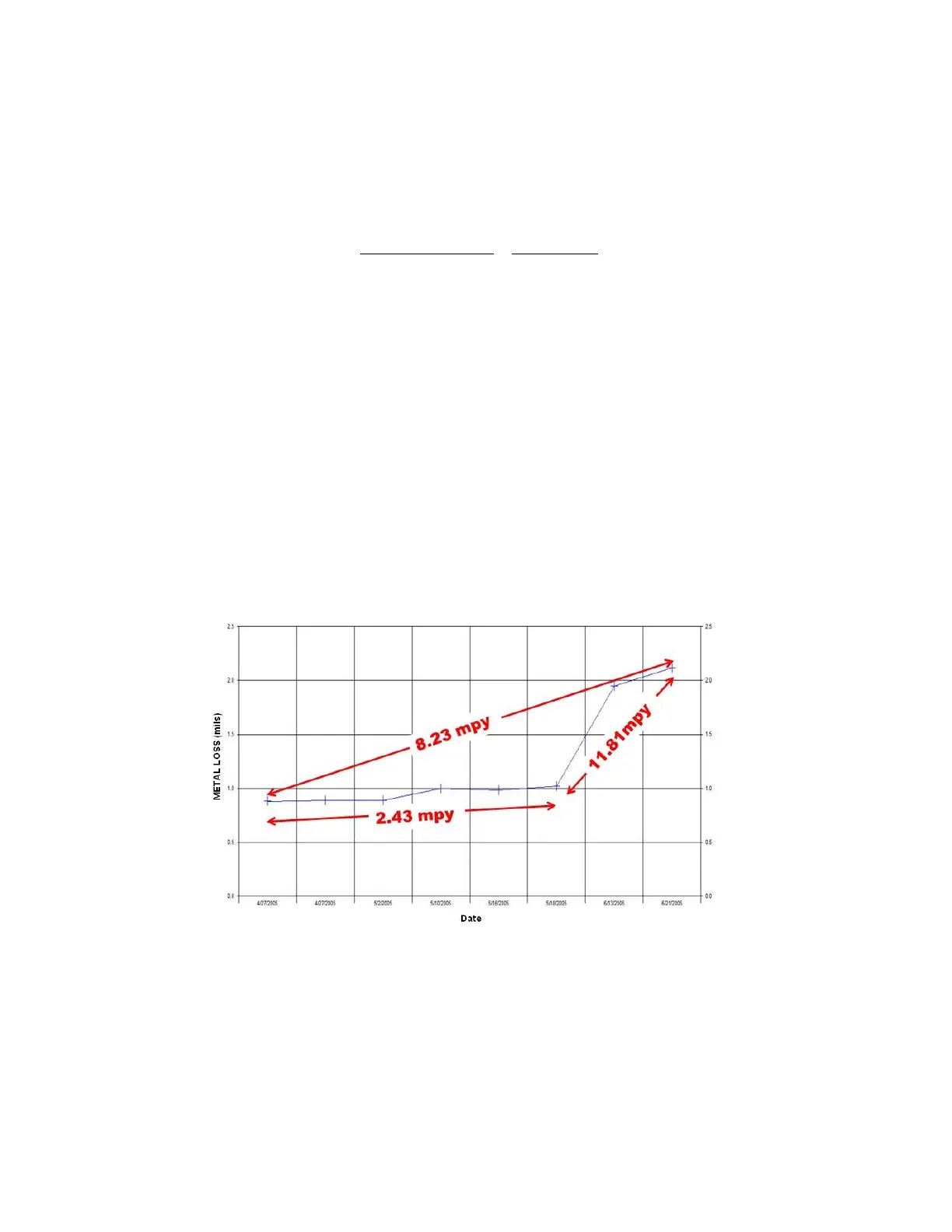

In some cases it may be necessary to review the raw Metal Loss data and manually apply the

Corrosion Rate formula to periods of interest. For example, look at the graph below and see how

much the calculated Corrosion Rate can vary depending on the time period used.

Figure 8. Corrosion Rates calculated from Metal Loss data

While each of the results is valid for the selected time period, the one of most interest is the value of

11.81 mpy which represents some type of system upset. When the Corrosion Rate is calculated

automatically on a pre-selected time period, there is no guarantee that the selected time period will

always coincide with system upsets such as this. That is why manual review and interpretation of

Metal Loss data is also helpful.

Loading...

Loading...