4 2 BAC 70 en

3.1 Replacement of the sealing element

Please proceed as follows when you want to replace

the Sealing element on the heavy-duty valve:

1. Remove the heavy-duty valve when it is in the 0° position

(completely closed). Instructions on how to remove the

valve can be found in section 1 of the instruction manual

2B70.

2. Secure the heavy-duty valve in position, so that it

cannot move or tip over.

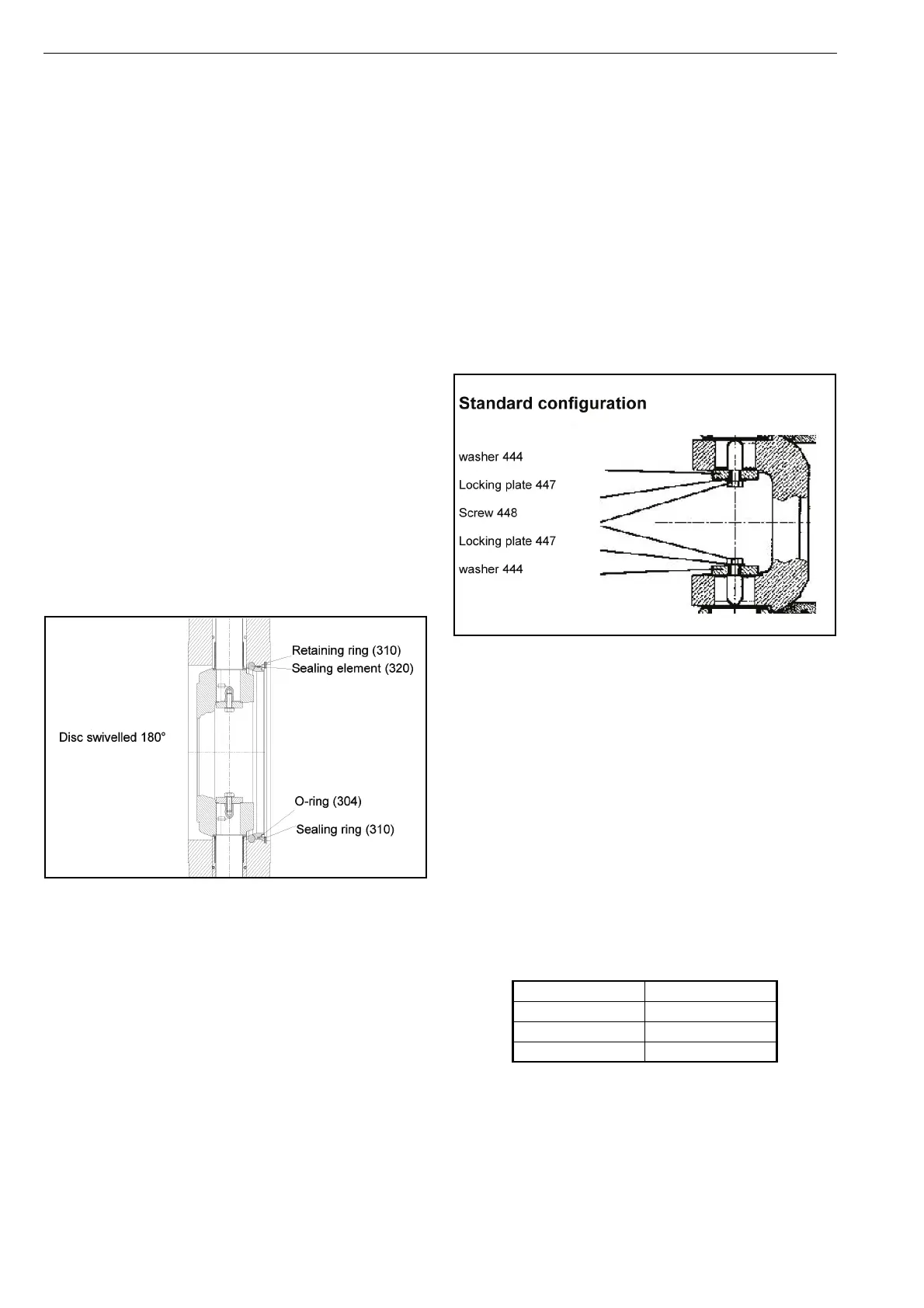

3. Swivel the Shut-off disc 180°, so that the sealing ele-

ment is exposed. Secure the shut-off disc - for

example with wooden wedges - in order to eliminate

the danger of scraching the parts. Make sure that

you do not damage the sealing area of the disc

while you are doing this.

4. Remove the retaining ring (see the sectional draw-

ing). The sealing ring is now exposed and can be

removed. If it is stuck, you can screw screws into the

two threads of the sealing ring and remove it with

their help.

5. Replace the sealing element (320), the O-ring (304)

and the sealing ring (301) now. Fit the retaining ring

(310) again as a final operation (see the illustration

on page 6).

6. Check that the heavy-duty valve is tight before

installing it again. Information about the installation

operations can be found in section 1 of the instruc-

tion manual 2B70.

Fig. 3 Replacement of the o-ring

3.2 Replacement of mechanical parts

Proceed as follows to replace mechanical parts:

1. Remove the adapter first of all.

2. Swivel the shut-off disc 180° C, so that the sealing

element is exposed. Secure the shut-off disc - for

example with wooden wedges - in order to eliminate

the danger of crushing. Make sure that you do not

damage the sealing area of the Shut-off disc while

you are doing this.

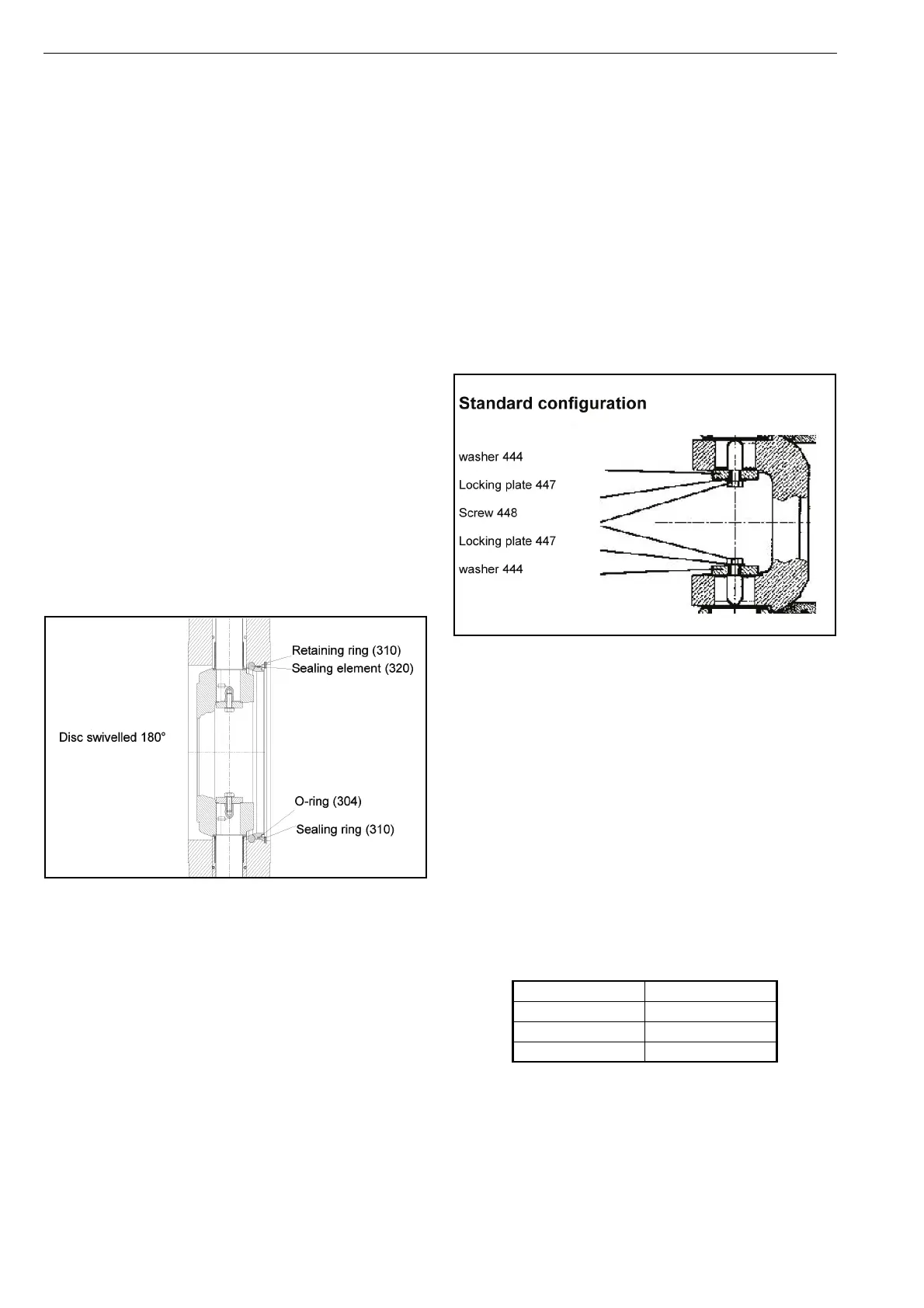

3. On standard versions of Type A that are designed for

particularly high pressure levels, you need to undo

two Screws (448) and remove the washer (444) as

well as the safety plate (447) (see the figure below).

4. Undo the screws (433) and remove the cover (430

and 437) (see the figure on page 9).

5. Undo the screws (432) on the two bearing bushings

(410).

6. Put two screws in the threads and pull the bearing

bushing and the shaft out.

You can now replace the following parts:

• the shaft (402),

• the actuator shaft (401),

• the bearing bushings (410, 424),

• the O-rings (470, 419),

• the backup rings (476),

• the U-ring (475),

• the thrust bearing (404, 405) and

• the disc (202).

7. Installation is carried out by completing the same

operations in the opposite order. Attend the torque

for the screws (448). They shall be mounted with a

special grease and the torque meter.

8. Check that the valve is tight before fitting it again.

Information about the installation operations can be

found in section 1 of the instruction manual 2B70.

Size MT [Nm]

M8 20

M10 45

M12 70

Loading...

Loading...