1 X 70 en 3

1 GENERAL

1.1 Scope of the manual

This manual provides the essential information on the

use of XT/XA-series ball valves. For further information

on actuators and other instruments, which are covered

only briefly, please refer to separate manuals on their

installation, use and maintenance.

1.2 Valve description

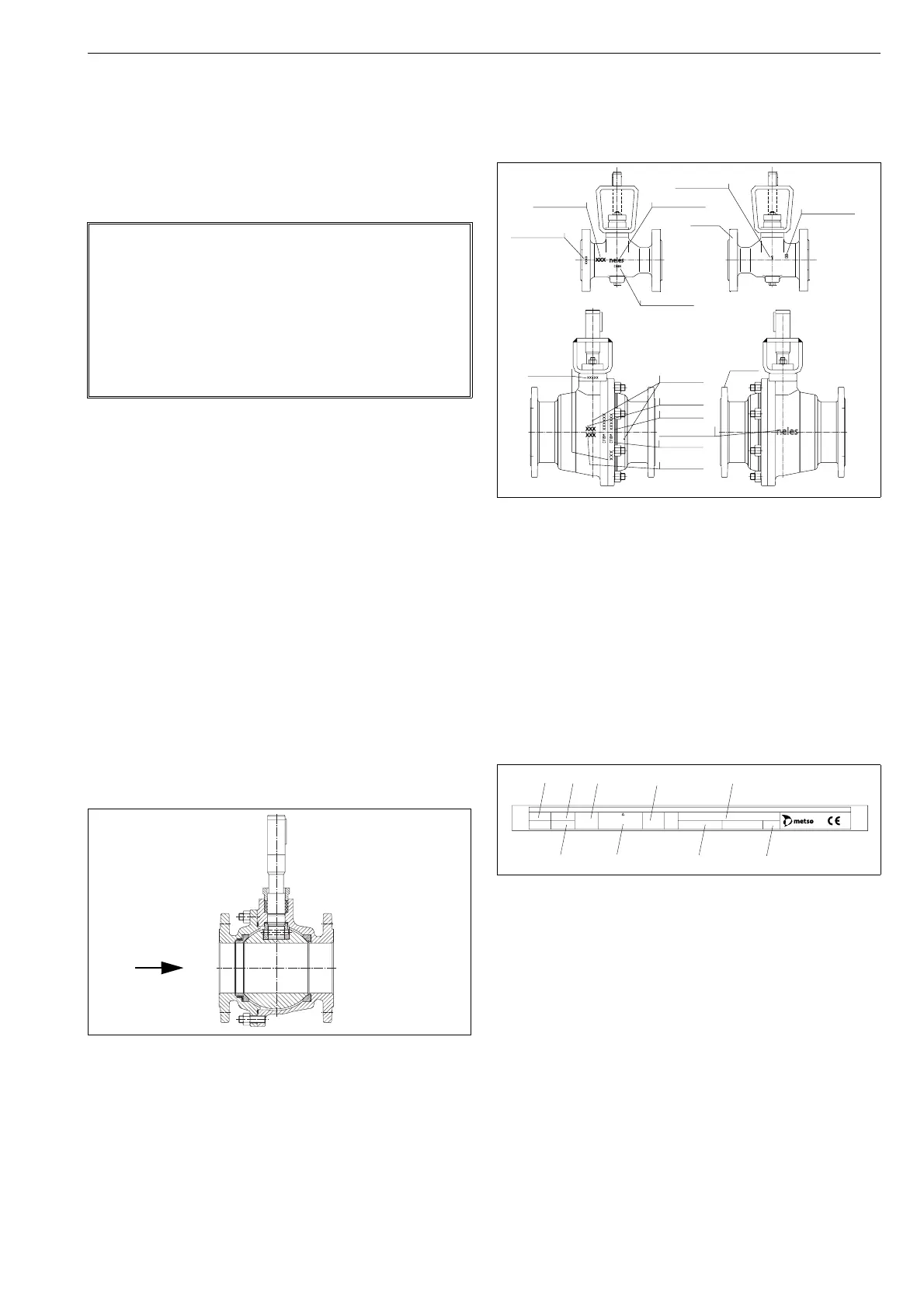

XT/XA-series valves are flanged ball valves and are

either metal or soft seated. Valves have two-piece bod-

ies with bolted body joints. The ball and the shaft are

separate parts and a shaft blow-out is prevented by a

separate thrust ring/pin and retaining plates.

A spline driver transmitting the shaft torque to the ball

connects the shaft with the ball. In 1" and 1 1/2" valves

the shaft directly drives the slot in the ball (no separate

driver).

The valve is tight in both flow directions. Tightness is

based on pipe pressure, i.e. the pressure differential

over the valve forces the ball against the downstream

seat. The arrow in Figures 1 and 2 shows the recom-

mended flow direction with H seat construction.

The construction of the valves may vary in accordance

with customers’ wishes. The construction details are

indicated in the type code in the identification plate. For

more information about the type code, see section 12.

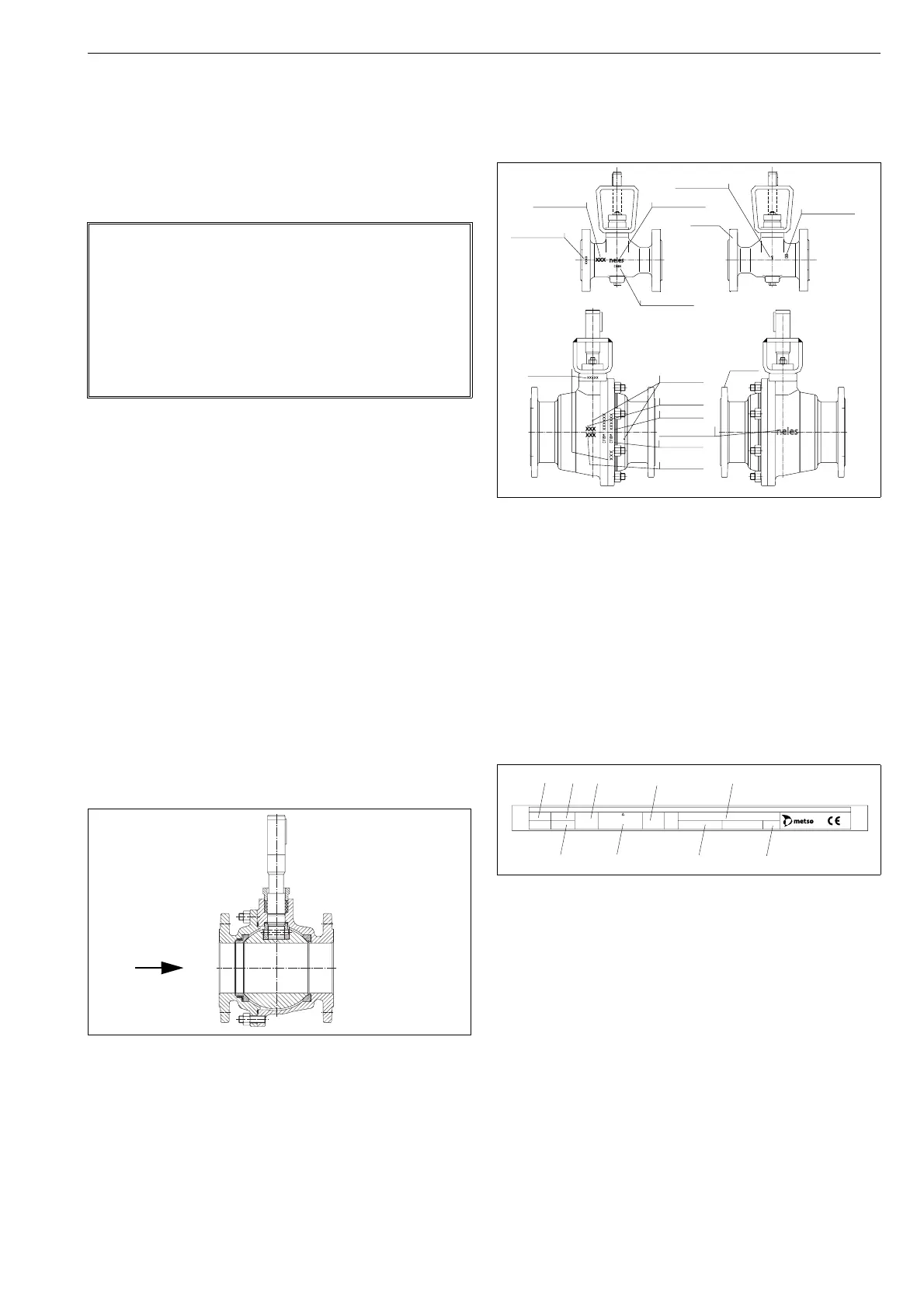

1.3 Valve markings

Body markings are cast or stamped on the body (see Fig-

ure 2). The identification plate (Figure 3) is on the valve

flange.

Identification plates have the following markings:

1. Body material

2. Shaft material

3. Trim material

4. Seat material

5. Maximum and minimum operating temperatures

6. Maximum shut-off pressure differential/temperature

7. Pressure class

8. Type code

9. Number of the list of valve manufacturing parts

10. Model

NOTE:

As the use of the valve is application-specific, a

number of factors should be taken into account when

selecting the application. Therefore, some of the situa-

tions in which the valves are used are outside the

scope of this manual.

If you have any questions concerning the use or appli-

cation of the valve, contact Metso’s Automation busi-

ness for more information.

Fig. 1 Construction of an XT/XA-series valve,

sizes 1"-8"

Recommended

flow direction for

valves with H seat

Fig. 2 Valve markings

Fig. 3 Identification plate

Batch number

Nominal size

Id plate

Body material

Batch number

Id plate

Foundry’s

Nominal size

Pressure class

Body material

Manufacturer’s

Casting no.

Foundry’s mark

mark

Manufacturer’s

mark

mark

Casting no.

BODY

TRIM

SHAFT

SEAT

T max

T min

MAX. OPER. ps

at

RATING TYPE

No.

MOD

ATTENTION : READ INSTRUCTIONS BEFORE INSTALLATION OR SERVICING. CONTACT METSO AUTOMATION FOR COPY.

MADE BY METSO AUTOMATION

XXXX

(1) (2) (5) (7) (8)

(3)

(4)

(6) (9)

(10)

Loading...

Loading...