MGL Avionics Stratomaster Ultra “L” Owner’s manual

Page 77

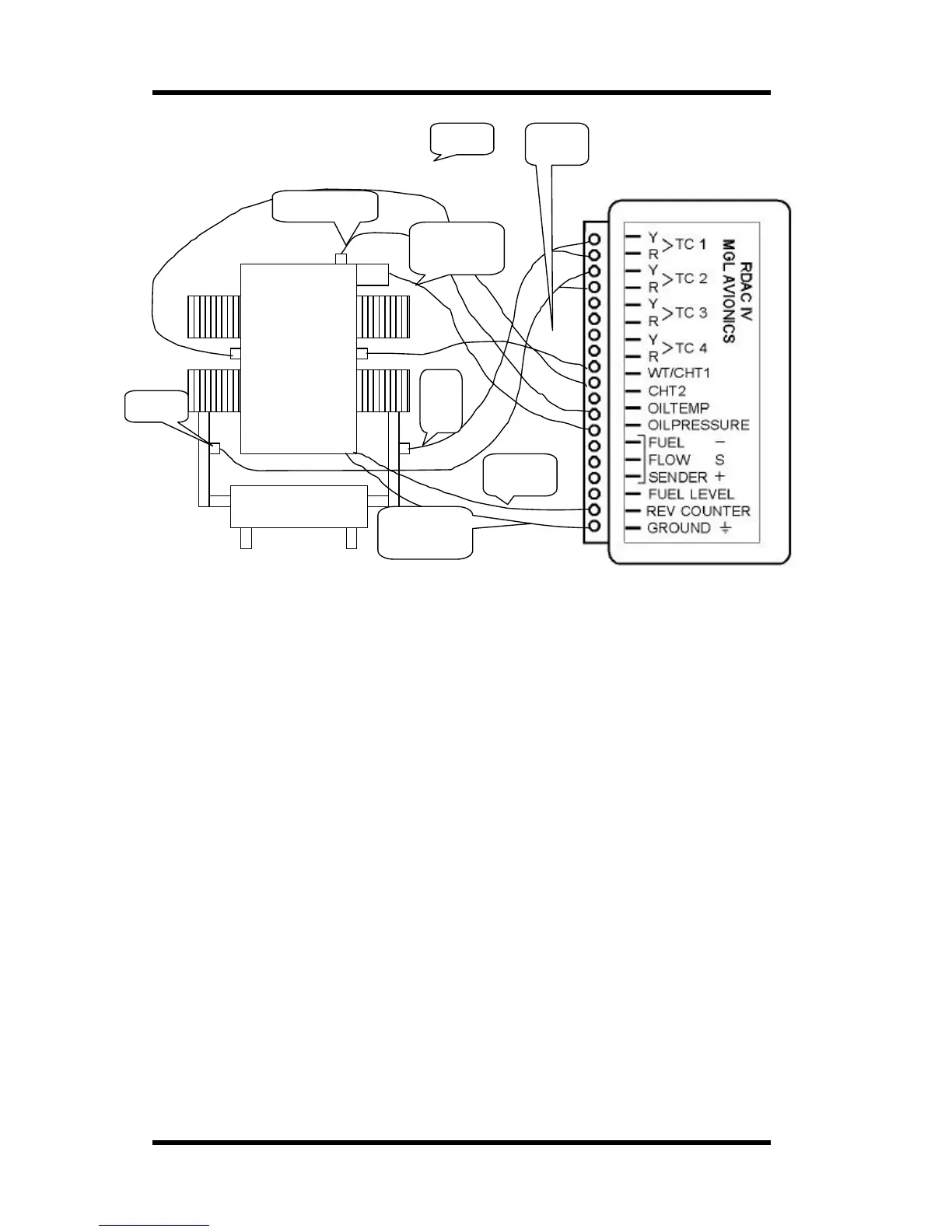

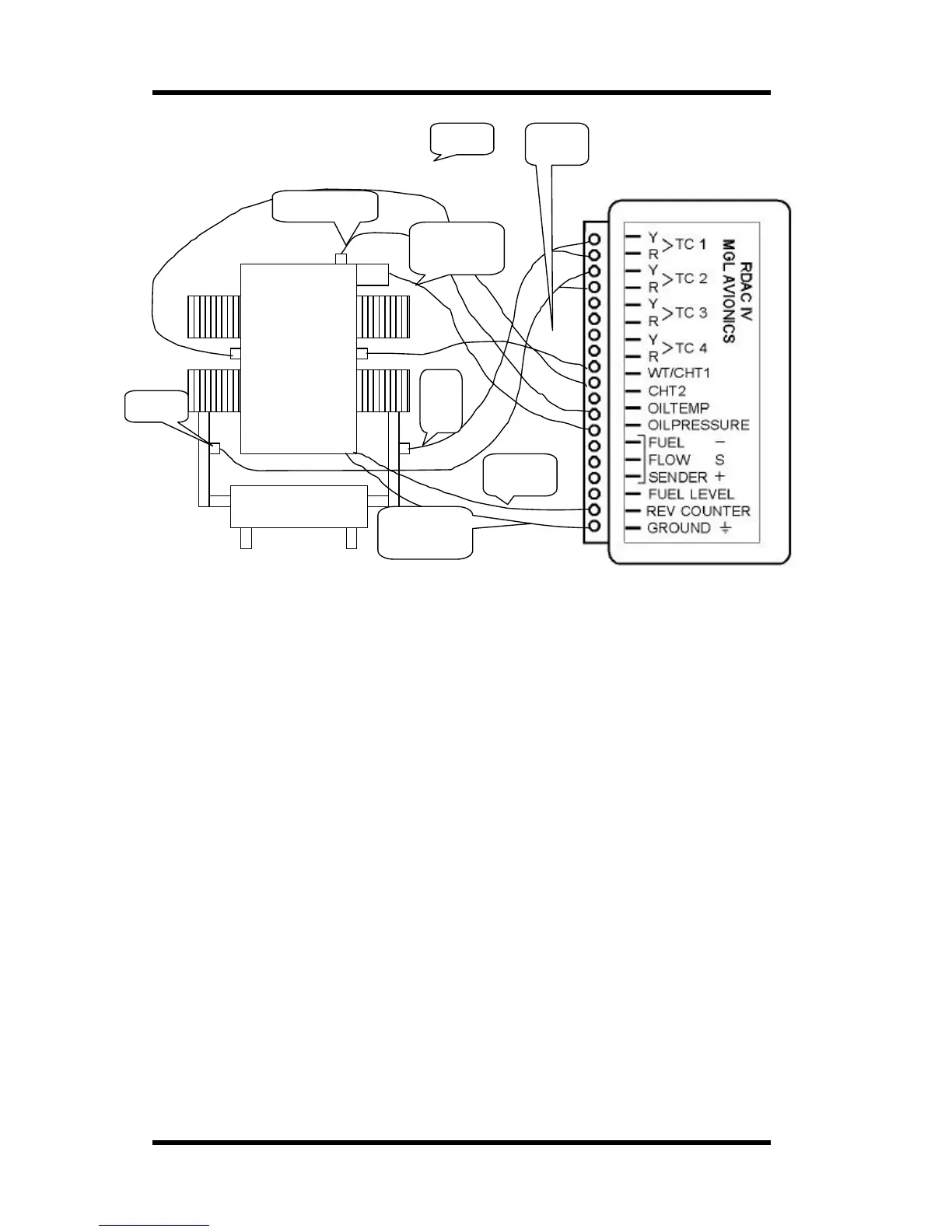

Connecting a Rotax 912

The Rotax 912/914 contains two built in NTC type CHT temperature senders. In addition oil

temperature and oil pressure sender is provided as standard.

Due to the fact that the 912 has two carburetors (one for each side of the engine), two EGT

probes should be connected, one for each exhaust stack. You can connect four EGT probes if

you like. In this case the relevant EGT displays will indicated the highest reading of any two pairs

of probes. You would use TC1 and 3 as one pair and TC2 and 4 as the other pair. Each pair

monitors one side of the engine.

CHT1 and CHT2 connect to the standard CHT senders, again one for each side. Connect oil

pressure and oil temperature and you are done.

In the Stratomaster Ultra, use “Engine quick select” to choose the 912 setup and then use

“Engine detail setup” to change any settings to your liking.

Connect the Rev counter wires (blue/yellow and white/yellow) as follows: One of the two wires to

the Ground terminal of the RDAC, the other to the REV counter input. It is recommended to also

connect the supplied 220 ohm ballast resistor. Connect one end to the Rev counter input, the

other to the Ground terminal of the RDAC.

Do not forget to set the “rev counter setup” in the “Basic setup menu”. Select a value of 10 as the

engine generates one pulse for every revolution.

Please note: Most of the senders are “grounded configurations” This means they connect

electrically to the engine block. It is vital for good and stable readings that you connect the

“Ground” terminal of the RDAC to the engine block using a short, good quality electrical

connection.

CHT

OIL temp

EGT

E

G

T

REVS

OIL

pressure

GROUND

CHT

Loading...

Loading...