R410A All DC Inverter V5 X Series 50Hz MCAC-VTSM-2015-10

114 Installation

b. All pipe joints shall be insulated.

Cautions:

1. Ensure no gaps exist in insulation material joints.

2. Any tape must be applied with appropriate pressure. If applied too tightly insulation may shrink and lose its

insulating properties leading to condensation and loss of efficiency.

3. In indoor shield space, it is no necessary to bind belting, so as to avoid influencing insulation effect.

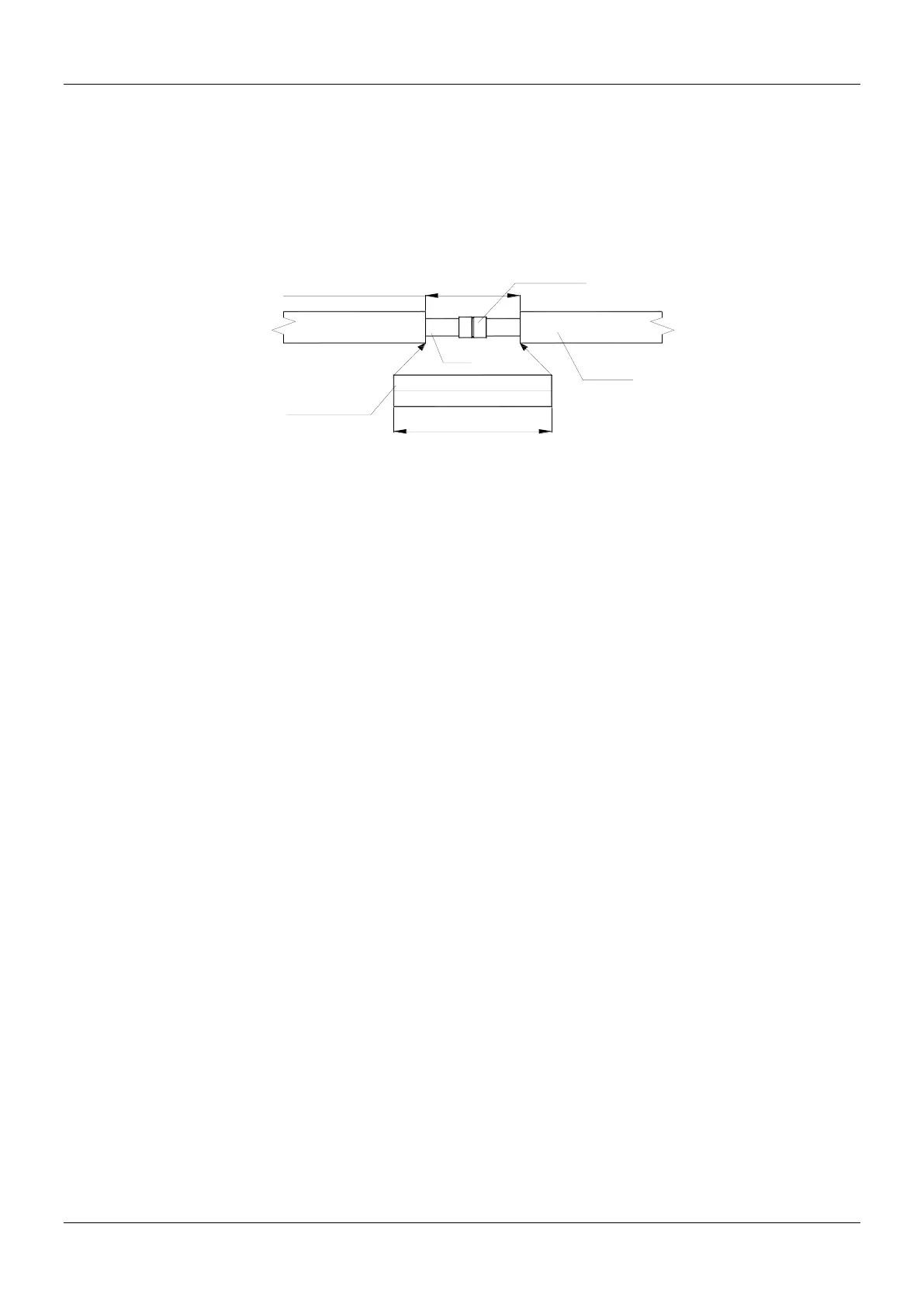

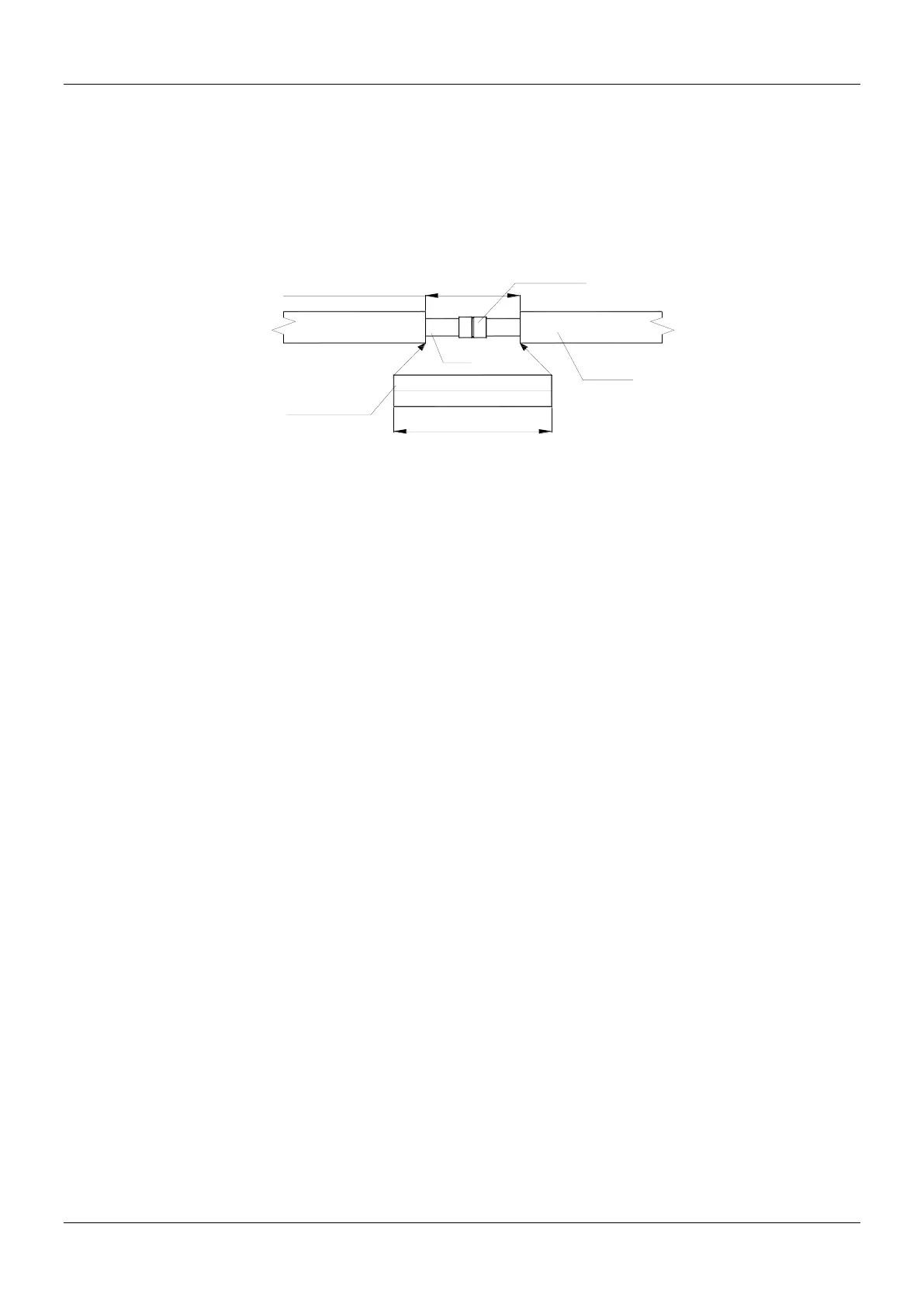

Correct repairing method for insulation cotton: (see the figure below)

Copper pipe

Insulation

cotton

19-11/16(500mm)

11-13/16"(300mm)

straight-through joint

Insulation cotton

Firstly cut out the material longer than gap, expend the two ends and embed the insulated cotton, at last, paste

joint with glue.

Main points of insulation repairing:

1. Repaired length of insulation (insulation tube with filled gap) shall be 50~100mm longer than the exposed

area.

2. Sliver the cut of insulation to be repaired and cross-section shall be even.

3. Insert gap with insulation for repairing and cross-section shall be pressed tightly.

4. All cross-section and cut need to be pasted with glue.

5. Finally, bind the seam with rubber/plastic tape.

6. Prohibit conducting insulation by using binder fabric in concealed section, so as to avoid influencing

insulation effect.

7.2 Insulation of Condensation Pipe

1. Select rubber/plastic tube with a fire retardant of B1 rating.

2. Thickness of insulation layer is usually above 10mm.

3. The insulation material at water outlet should be fixed with glue to the unit body, so as to avoid condensation

and dripping.

4. No insulation will be implied if installed in a wall.

5. Use specified glue to seal the seam of insulation material, and then bind with cloth tape. The width of tape

shall not be less than 50mm. Ensure tape is fixed firmly to avoid condensation.

7.3 Duct insulation

1. Duct insulation

1) Insulation of duct parts and equipment should be conducted after confirming that the leakage test has been

completed and quality of duct is confirmed.

2) Common insulation materials include centrifugal glass cotton, rubber/plastic materials etc..

2. Insulation layer should be even and tight. Cracks, gaps and other defects are not allowed.

3. The supporting, hanging and mounting brackets of duct should be fixed on the outside of the insulation layer,

and insert bed timber between bracket and duct.

4. Thickness of insulation layer

1) When inlet and outlet duct are installed in rooms with no air-conditioning, the insulation thickness should be

above 40mm when adopting centrifugal glass cotton for insulation.

2) When inlet and outlet duct are installed in a room with air conditioning, insulation thickness should be above

25mm when adopting centrifugal glass cotton for insulation.

Loading...

Loading...