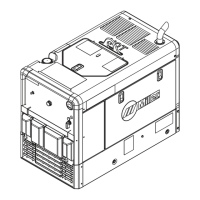

This document is the owner's manual for the Miller Bobcat™ 260 Diesel, an engine-driven welder/generator designed for various welding processes and auxiliary power generation.

Function Description

The Miller Bobcat™ 260 Diesel is a versatile, engine-driven machine that combines welding capabilities with auxiliary power generation. It supports multiple welding processes, including:

- Stick (SMAW) Welding: This is a common manual arc welding process that uses a consumable electrode covered with flux to lay the weld.

- MIG (GMAW) Welding: A semi-automatic or automatic process that uses a continuous wire feed as an electrode and a shielding gas to protect the weld from contamination.

- Flux Cored (FCAW) Welding: An arc welding process that uses a continuous wire feed containing a flux core, which provides shielding gas and slag protection.

- TIG (GTAW) Welding: A manual arc welding process that uses a non-consumable tungsten electrode and an inert shielding gas to produce high-quality welds.

In addition to welding, the unit functions as a generator, providing AC power for auxiliary equipment. This dual functionality makes it suitable for various job site applications where both welding and electrical power are needed.

Important Technical Specifications

The Bobcat™ 260 Diesel features several key technical specifications:

Welding Output:

- CC/AC Mode: 40-260 Amperes weld output range, with a rated output of 260 A, 25 V at 100% Duty Cycle. Maximum Open-Circuit Voltage (OCV) is 80 V.

- CC/DC Mode: 40-260 Amperes weld output range, with a rated output of 260 A, 25 V at 100% Duty Cycle. Maximum OCV is 80 V.

- CV/DC Mode: 17-28 Volts weld output range, with a rated output of 275 A, 25 V at 60% Duty Cycle, and 250 A, 28 V at 100% Duty Cycle. Maximum OCV is 41 V.

Generator Power Rating:

- Peak: 11.0 kVA/kW

- Continuous: 9.5 kVA/kW Single-Phase 80/40 A, 120/240 VAC 60 Hz (while not welding).

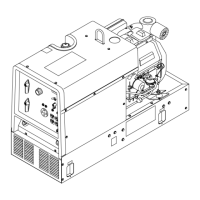

Engine:

- Type: Kubota D722 Water-Cooled, Three-Cylinder, Four-Cycle Diesel Engine.

- Horsepower: 19 HP at 3600 RPM (Weld Speed).

- Idle Speed: 2450 RPM.

- Fuel Capacity: 12 gallons (45 L).

- Oil Capacity: 3.4 quarts (3.2 L).

- Sound Level: 79.5 dB (105.0 Lwa) at 7 m at rated output.

Environmental Specifications:

- Operating Temperature Range: -20 to 104°F (-29 to 40°C). Output is derated at temperatures above 104°F (40°C).

- Storage/Transportation Temperature Range: -40 to 131°F (-40 to 55°C).

Dimensions and Weight:

- Lifting Eye Weight Rating: 1250 lb (567 kg).

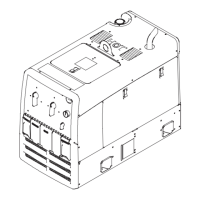

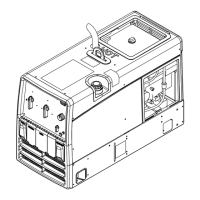

- The manual provides detailed diagrams with overall dimensions for installation and mounting.

Usage Features

The Bobcat™ 260 Diesel is designed for ease of use and operational flexibility:

- Front Panel Controls: The unit features an Engine Control Switch (Off, Run/Idle, Start), a Glow Plug Switch, a Fuel Gauge/Maintenance Display, a Weld Process Selector Switch (Stick, TIG, Wire), a Coarse Range Switch, and a Fine Control knob for precise amperage or voltage adjustment.

- Wireless Remote: An optional wireless remote allows for engine start/stop functionality from a distance, enhancing convenience and safety on the job site. LED indicators on the remote provide feedback on communication, cranking, and engine status.

- Weld Output Terminals: Clearly marked terminals for Work and Electrode connections ensure proper setup for various welding processes.

- Generator Power Receptacles: Includes 120/240 V 50 A AC receptacle (RC1) and two 120 V 20 A AC GFCI receptacles (RC2 and RC3) for auxiliary power. Supplementary protectors (circuit breakers) are in place to protect against overloads.

- Simultaneous Weld And Power: The unit can provide both welding current and auxiliary power simultaneously, with a detailed table outlining available kVA/kW at different weld current levels.

- Engine Speed Adjustment: Instructions are provided for adjusting idle and weld/power speeds to optimize performance.

- Welding Guidelines: The manual includes typical connection diagrams and control settings for Stick, MIG, and TIG welding, along with guidance on electrode selection, arc striking, electrode positioning, and identifying common weld bead characteristics (e.g., spatter, penetration, fusion).

- Generator Power Guidelines: Detailed information on selecting extension cords, power requirements for industrial motors and farm/home equipment, and grounding procedures for supplying building systems.

Maintenance Features

Regular maintenance is crucial for the longevity and optimal performance of the Bobcat™ 260 Diesel. The manual provides a comprehensive maintenance schedule and troubleshooting guide:

- Maintenance Label: A label on the unit provides quick reference for fluid specifications and maintenance intervals.

- Routine Maintenance Schedule:

- Every 8 Hours: Check coolant level, fuel level, oil level, and inspect for oil/fuel spills.

- Every 200 Hours: Check fuel connections, oil, oil filter, air cleaner, engine speed, unreadable labels, weld and battery terminals, and belt tension.

- Every 400 Hours: Check fuel filters and weld cables.

- Every 1000 Hours: Check fan belt, flush radiator, inspect radiator hoses, air cleaner hoses, valve clearance (by authorized service agent), slip rings (by authorized service agent), and brushes (by authorized service agent).

- Every 2000 Hours: Check fuel hoses, coolant and hoses, and injectors (by authorized service agent).

- Replacing Air Cleaner: Step-by-step instructions for removing and installing the air cleaner, with a recommendation to replace it every 200 hours or less in severe conditions.

- Overload Protection: Information on fuses (F1, F2) and circuit breakers (CB7, CB8) that protect various circuits, along with instructions for resetting them.

- Engine Maintenance Activities: Detailed procedures for checking and changing engine oil, fuel lines, fuel filters, and coolant. Emphasizes the importance of using a 50/50 ethylene glycol base antifreeze and water solution.

- Adjusting Engine Speed: Instructions for checking and adjusting the fuel solenoid and throttle solenoid to ensure proper engine idle and weld/power speeds.

- Troubleshooting Tables: Extensive tables for diagnosing and resolving common issues related to welding output (low/no output, erratic output, high output), generator power (low/no output, erratic output, high output), and engine problems (cranking, starting, stopping, battery discharge, idle speed, weld/power speed). Specific troubleshooting for wireless remote issues is also included.

- Welding Troubleshooting: Guides for addressing common weld bead issues such as excessive spatter, porosity, excessive penetration, lack of penetration, incomplete fusion, burn-through, and waviness of bead, providing possible causes and corrective actions.

- Regulatory Approval: The device complies with Part 15 of the FCC rules, and warnings are provided regarding changes or modifications not expressly approved by the compliance party.

- California Proposition 65 Warnings: Important safety warnings regarding exposure to chemicals known to cause cancer and birth defects, especially concerning diesel engine exhaust.