OM-239 982 Page 14

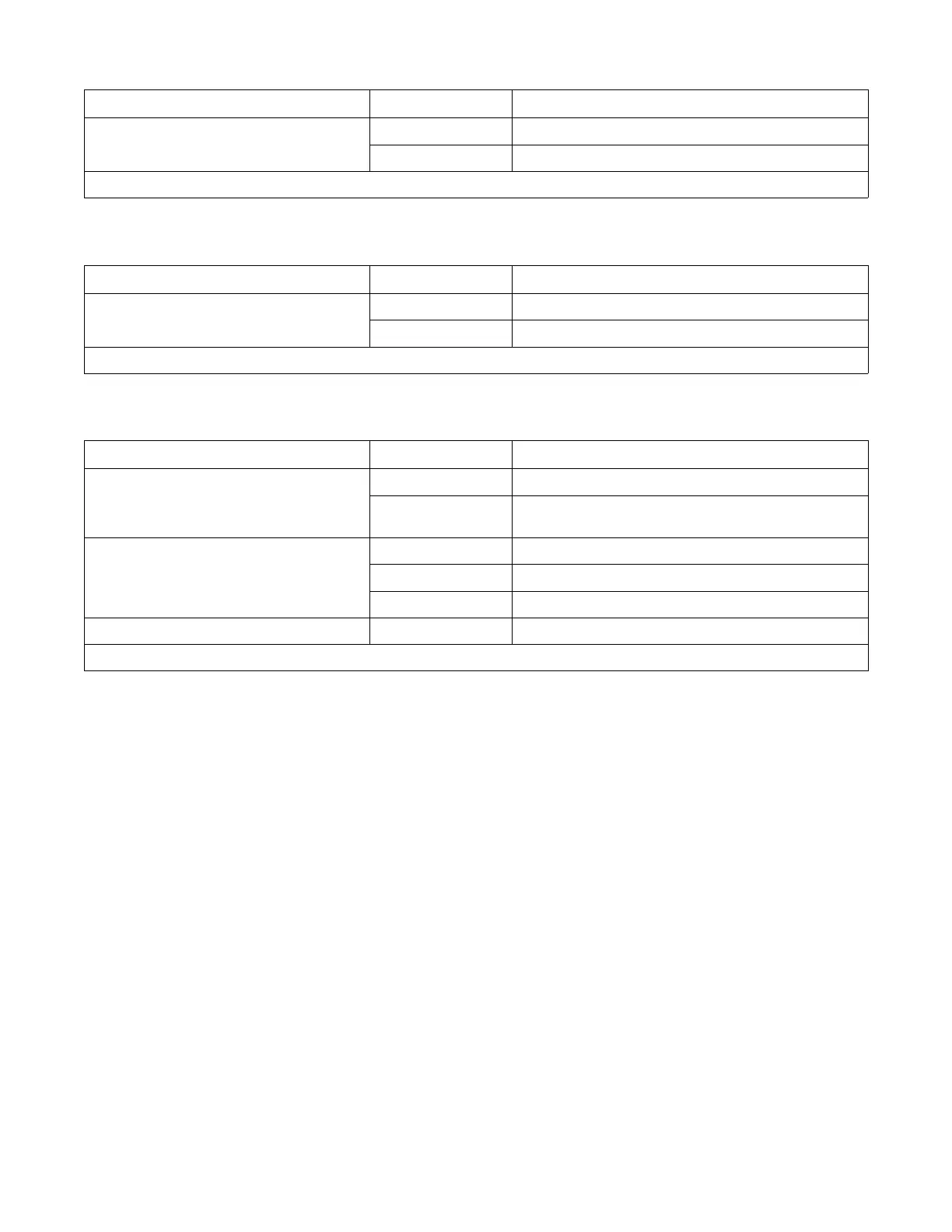

3-4. Remote Interface Cable Connector PLG2 Information

Plug PLG2 Socket* Socket Information

Left Trigger

1 Closure with pin 2 activates left trigger.

2 Closure with pin 1 activates left trigger.

*Sockets 3 and 4 are not used.

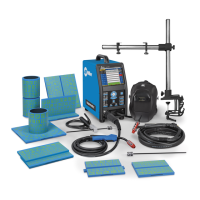

3-5. Remote Interface Cable Connector PLG3 Information

Plug PLG3 Socket* Socket Information

Right Trigger

1 Closure with pin 2 activates right trigger.

2 Closure with pin 1 activates right trigger.

*Sockets 3 and 4 are not used.

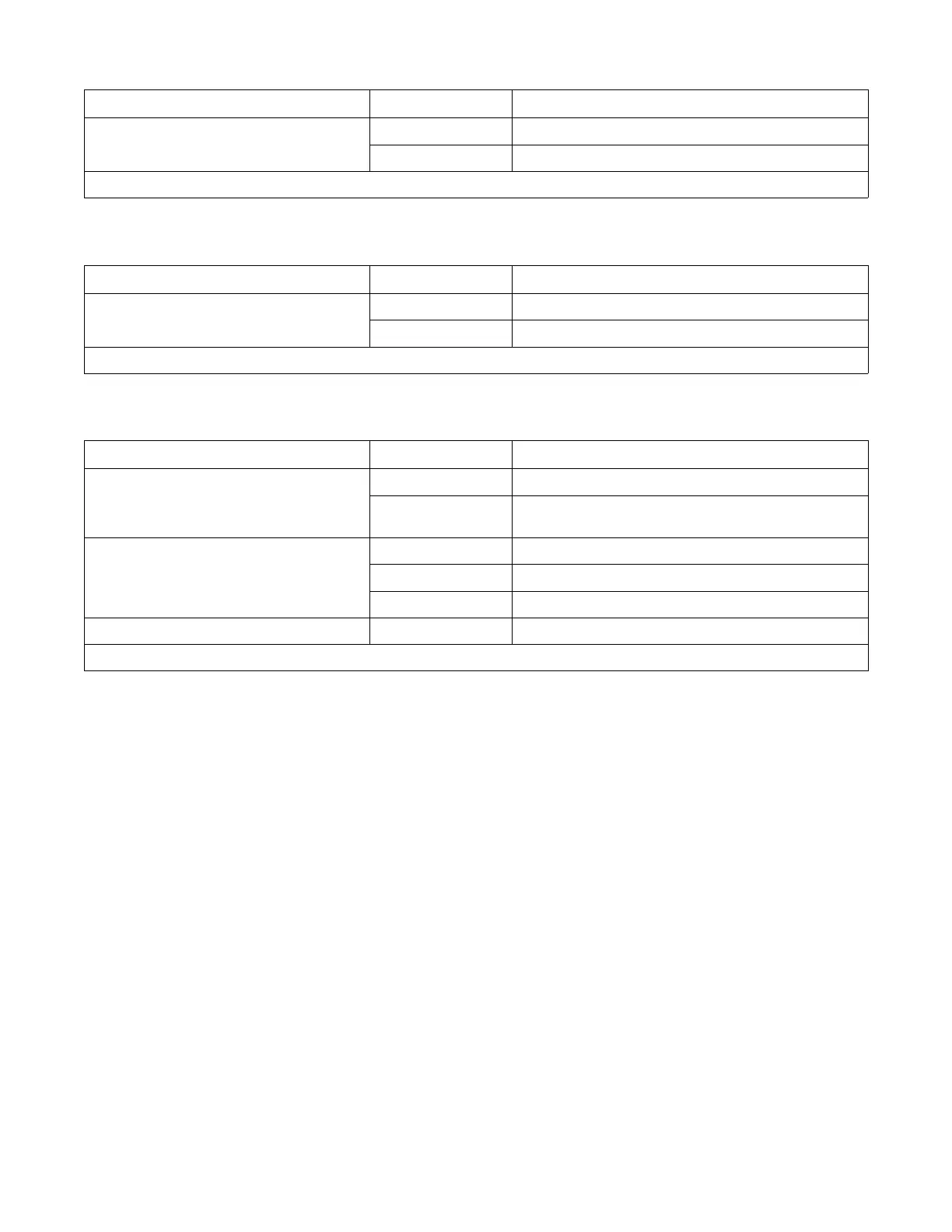

3-6. Remote Interface Cable Connector PLG4 Information

Plug PLG4 Socket* Socket Information

24 Volts AC Input

3 24 volts AC

6 24 volts AC return. Connected to chassis common. Completes

24 volts AC power supply circuit to remote interface.

Serial Communication

1 Isolated RS-485 (+) serial communication signal.

2 Isolated RS-485 (−) serial communication signal.

5 Isolated serial communication common.

GND 4 Chassis common.

*Socket 7 is not used.

Loading...

Loading...