8 www.millipore.com

S10: Integrity Testing

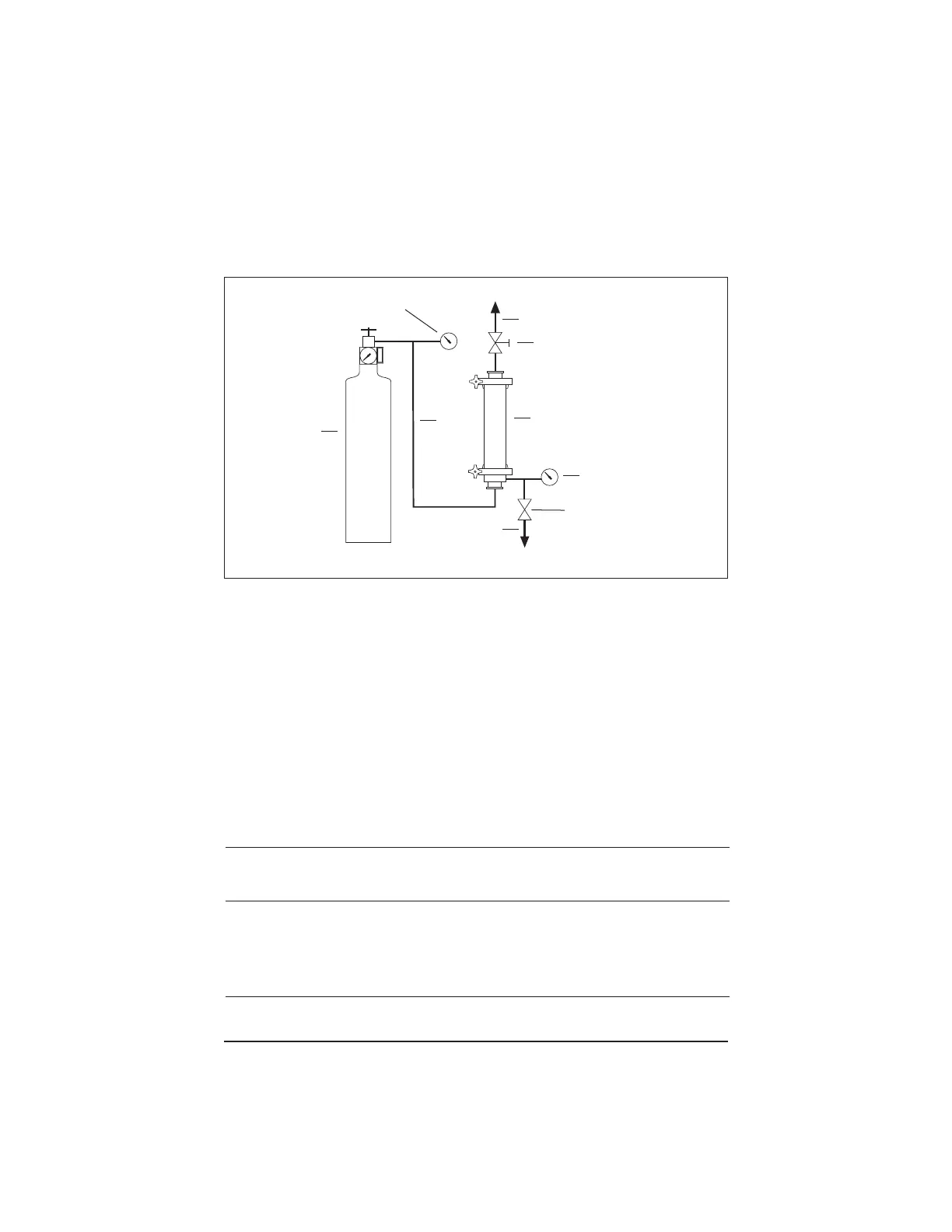

Figure 2 shows the configuration for integrity testing a spiral cartridge.

Figure 2. Configuration for Integrity Testing a Spiral Cartridge

1. Drain the plumbing of water. To remove any residual water, purge with

filtered nitrogen or clean, dry air at 1–2 psi (0.07–0.14 bar), if necessary.

2. Attach a regulated and filtered supply of nitrogen or clean, dry air to the feed

side of the cartridge housing.

3. Isolate the retentate manifold by closing the back-pressure valve. The

permeate port valve should be open.

4. Slowly raise the gas pressure to the value recommended for your cartridge

type, as shown in Table 1.

Table 1. Integrity Test Specifications for S10

Catalogue Gas Flow Rate Test Pressure

Number cc/min psig (bar)

CDUF010LC ≤ 60 10 (0.7)

CDUF010LG ≤ 60 5 (0.35)

CDUF010LT ≤ 150 5 (0.35)

Feed

line

Cartridge, installed

Gas supply

Retentate line

Permeate line

Permeate pressure

gauge

Back-pressure valve

Permeate

port valve

Feed pressure gauge

Loading...

Loading...