Preventive Maintenance

PELLERIN MILNOR CORPORATION

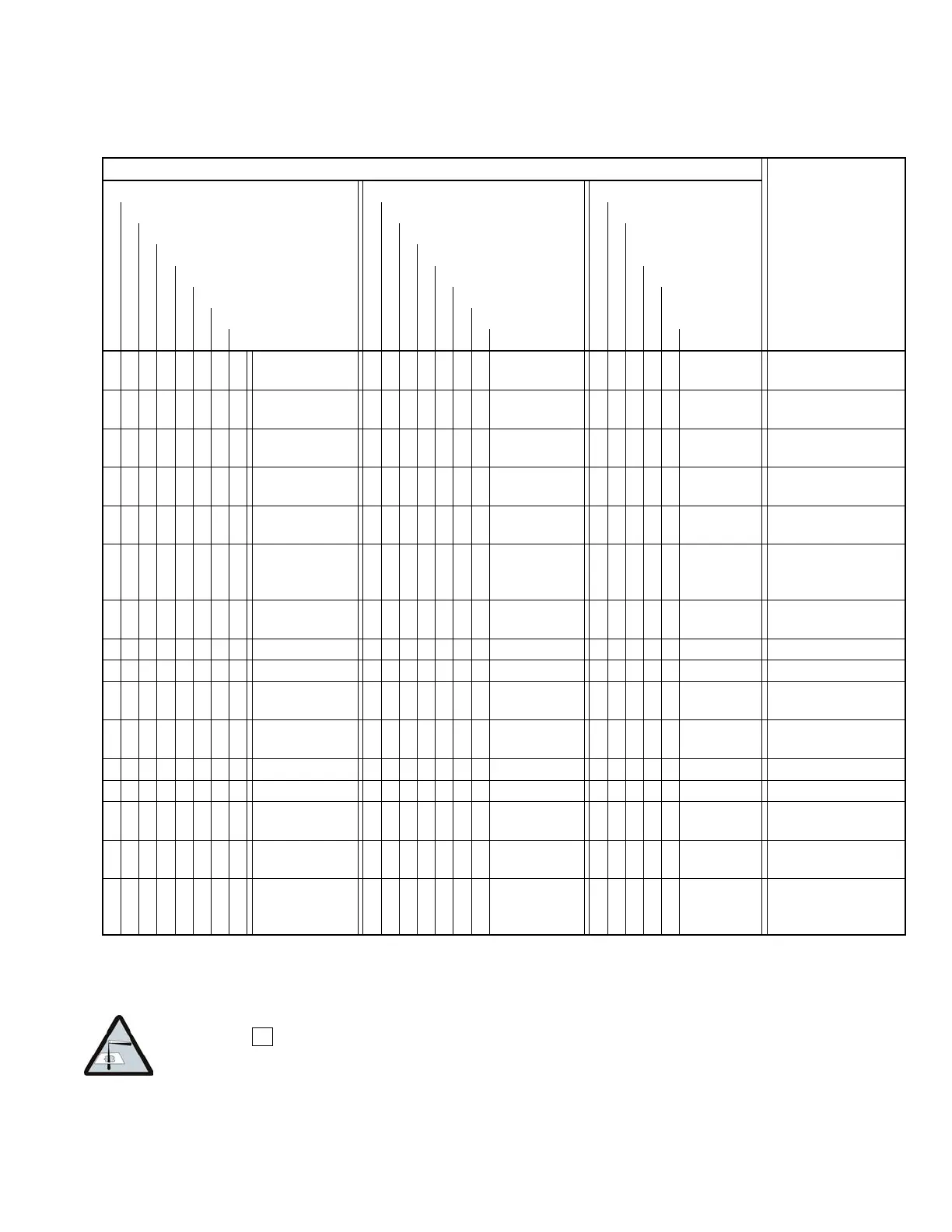

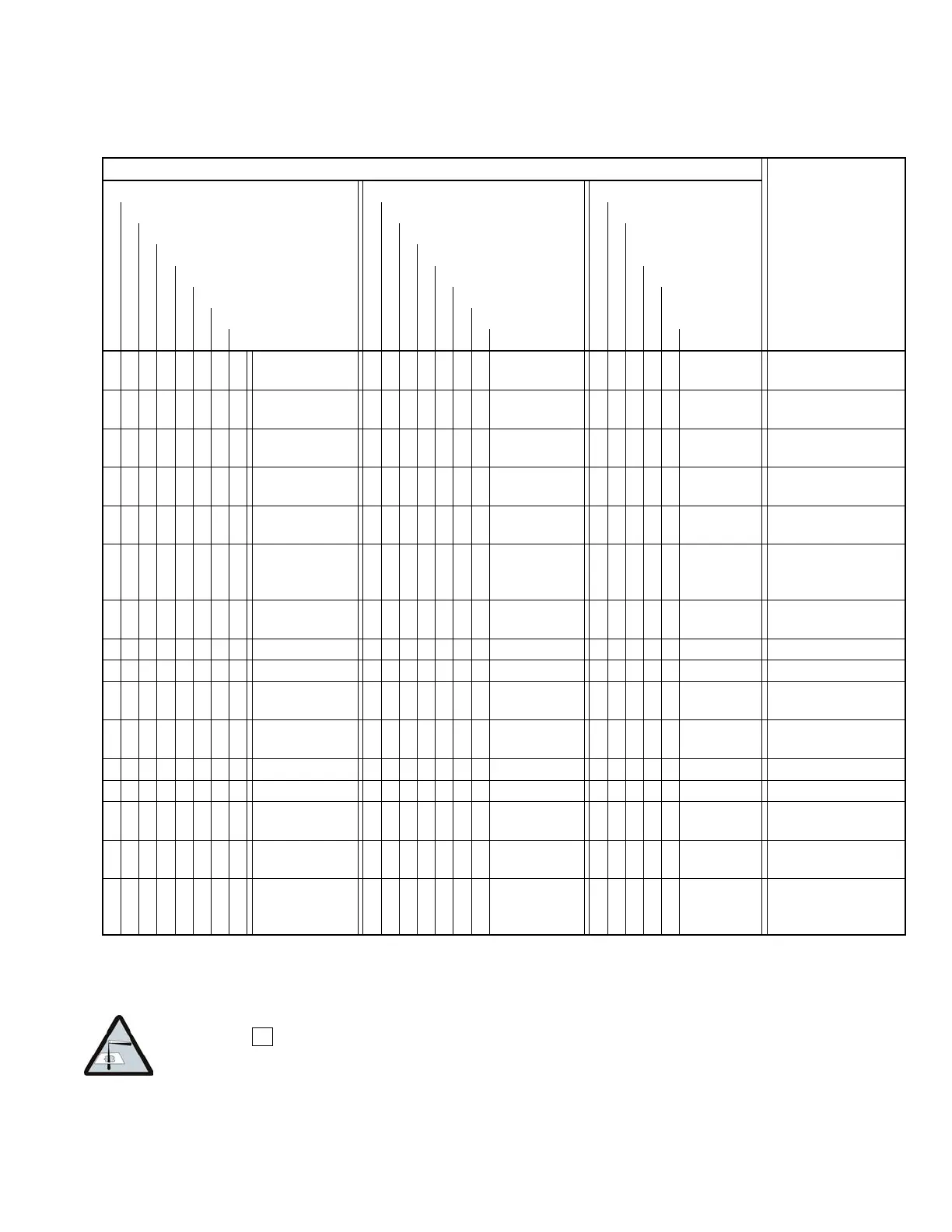

Table 1: Preventive Maintenance Items

Do this procedure

on this part at this interval to prevent this.

Examine. Replace if worn or missing. Each day = 8 hours of operation Injury

↓ Examine. Adjust if necessary. ↓ Week = 40 hours ↓ Immediate damage

↓ Examine. Tighten if loose. ↓ Month = 165 hours ↓

↓ Clean / vacuum ↓ 3 mo = 500 hr

Unsatisfactory

performance

↓ Add fluid if low ↓ 4 mo = 670 hr ↓ Costly repair

↓ Replace fluid ↓ 6 mo = 1000 hr ↓

↓ Add grease ↓ Year = 2000 hr

Unwanted

shutdown

↓ Other ↓ Other ↓ Other

Details

X

guards, covers,

safety placards

X X See Note 1

X X

anchor bolts and

grout

X X X

See "Dimensional

Drawing"

X X fasteners X X X

See "Torque Require-

ments for Fasteners"

X

inverter fans,

vents

X X X

See Section 1

X

all machine

areas

X

dirty parts

wear faster

X all electrical

terminals

X See also External

Fuse/Breaker...

Requirements

X X

components with

fluid leaks

X X

See also Section 5

X water strainers X X

X steam strainer X X See Section 4

X

soap chute,

chemical inlets

X X X

See Section 1

X X

motors See "Motor

Maintenance"

X

See "Motor

Maintenance"

X drive pulleys X X See Note 1

X drive belt X X X See Note 1

X

water pressure

for flush inlet

X X

See Section 3

X main bearing never not

applicable

These are sealed

bearings

X door interlock X X See Daily Test of

Door Interlock

(Reference Manual)

Note 1: See the data about this component in this service manual.

1.

Easy Procedures to Prevent Immediate Damage

CAUTION 3 : Risk of damage—Spilled chemical supplies can cause corrosion damage to

the machine and the goods.

• Remove chemical supplies from machine surfaces.

• Stop leaks. Do not let remaining chemical supplies go into the machine when it does not

operate.

37

Loading...

Loading...