3. POSITIONING SIGNALS

3 − 52

(2) PCPU error cause(D9184) ..............................Data from the PCPU to the SCPU

This register is used to identify the nature of errors occurring in the PCPU part

of the sequence program.

Error Code Error Cause Operation when Error Occurs Action to Take

1 PCPU software fault 1

2 PCPU operation synchronization time over

3 PCPU software fault 2

30 PCPU/SCPU hard ware fault

All axes stop immediately, after

which operation cannot be

started.

Reset with the reset key.

100 to 107

110 to 117

120 to 127

130 to 137

140 to 147

AC servo motor drive module CPU fault

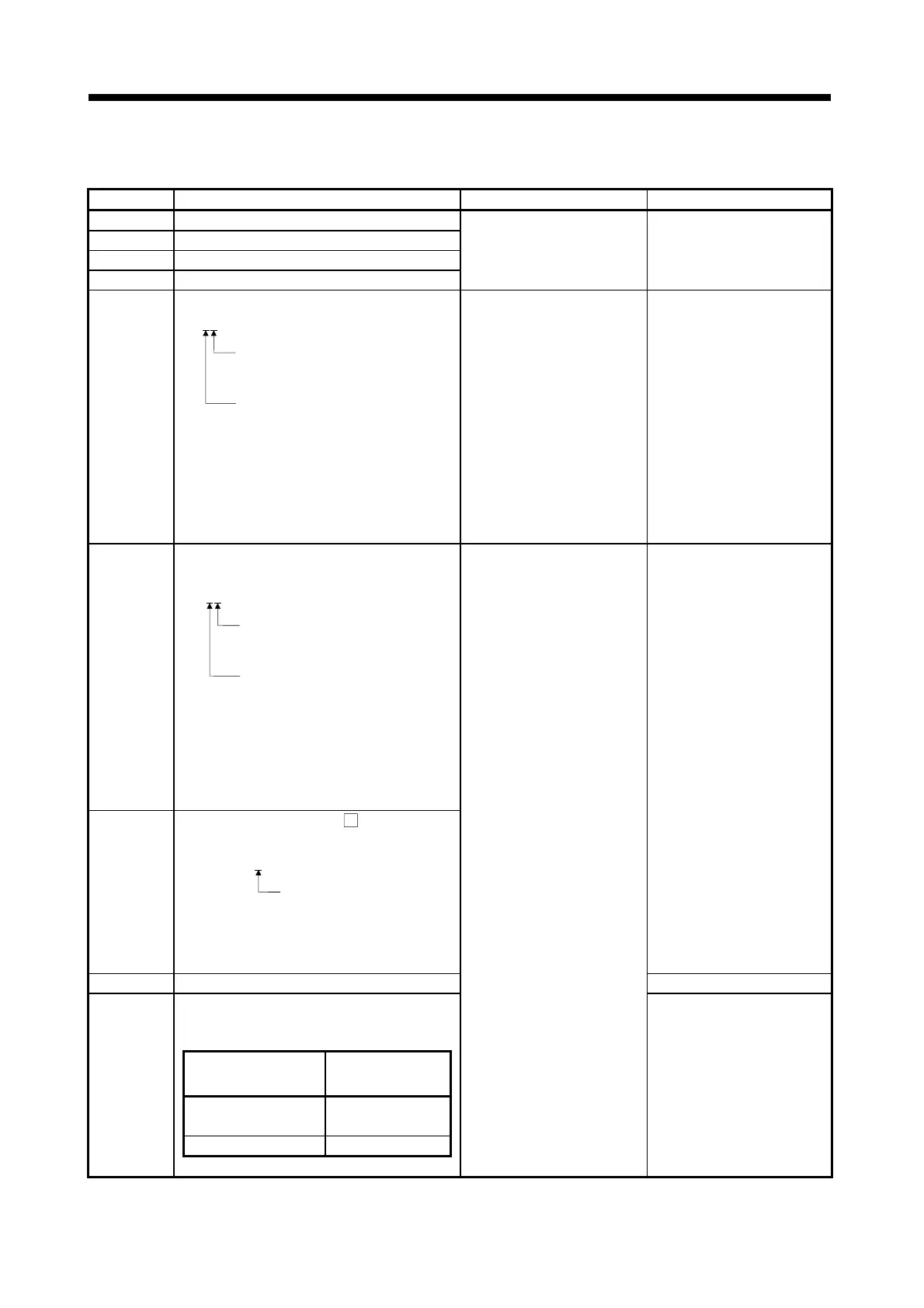

100

Indicates the slot No.(0 to 7)

where the AC motor drive module

with the fault is loaded.

Indicates the stage No. of the base

on which the AC motor drive module

with the fault is loaded.

0: CPU base

1: Extension base 1st stage

2: Extension base 2nd stage

3: Extension base 3rd stage

4: Extension base 4th sta

e

The servo error detection flag

(M2408+20n) of the

corresponding axis turns ON,

resulting in a servo-off status.

After that, operation is performed

in accordance with "ADU servo

error-time processing setting" in

system settings.

Perform reset with the key.

If the error occurs after reset,

change the ADU module since it

may be faulty.

200 to 207

210 to 217

220 to 227

230 to 237

240 to 247

Hardware fault of module loaded on motion CPU

base unit or extension base unit.

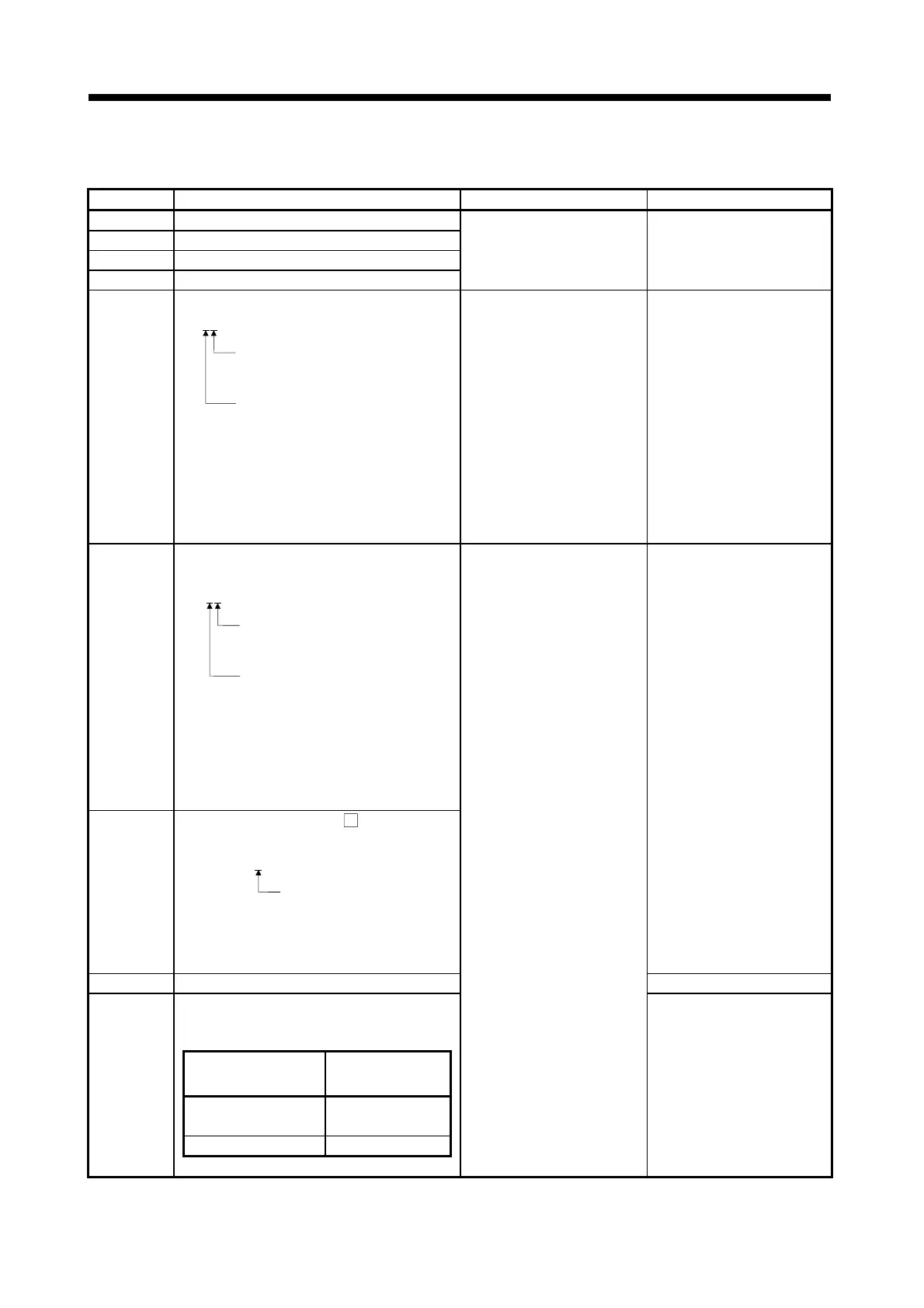

200

Indicates the slot No.(0 to 7)

where the module with the fault

is loaded.

Indicates the stage No. of the base

on which the module with the fault

is loaded.

0: CPU base

1: Extension base 1st stage

2: Extension base 2nd stage

3: Extension base 3rd stage

4: Extension base 4th stage

250 to 253

Separate servo amplifier (MR-

-B) interface

hardware fault

250

Faulty SSCNET No.

0: SSCNET 1

1: SSCNET 2

2: SSCNET 3

3: SSCNET 4

Reset with the reset key.

If the error reoccurs after

resetting, the relevant module or

the relevant slot(base unit) is

probably faulty: replace the

module/base unit.

300 PCPU software fault 3 Reset with the reset key.

8 or more points of CPSTART instruction were

used to start programs in excess of simultaneously

startable programs.

Number of

simultaneously

startable programs

Conventional

function version

20

Function added version 14

301

All axes stop immediately, after

which operation cannot be

started.

Perform reset with the key.

Use 8 or more points of

CPSTART instruction to start

programs within the number of

simultaneously startable

programs.

Loading...

Loading...