7. POSITIONING CONTROL

7 − 36

7.6 Circular Interpolation Using Auxiliary Point Designation

Circular interpolation control by designating the end point address and auxiliary

point address (a point on the arc).

Circular interpolation control using auxiliary point designation uses ABS

(absolute data method) and INC (incremental method) servo instructions.

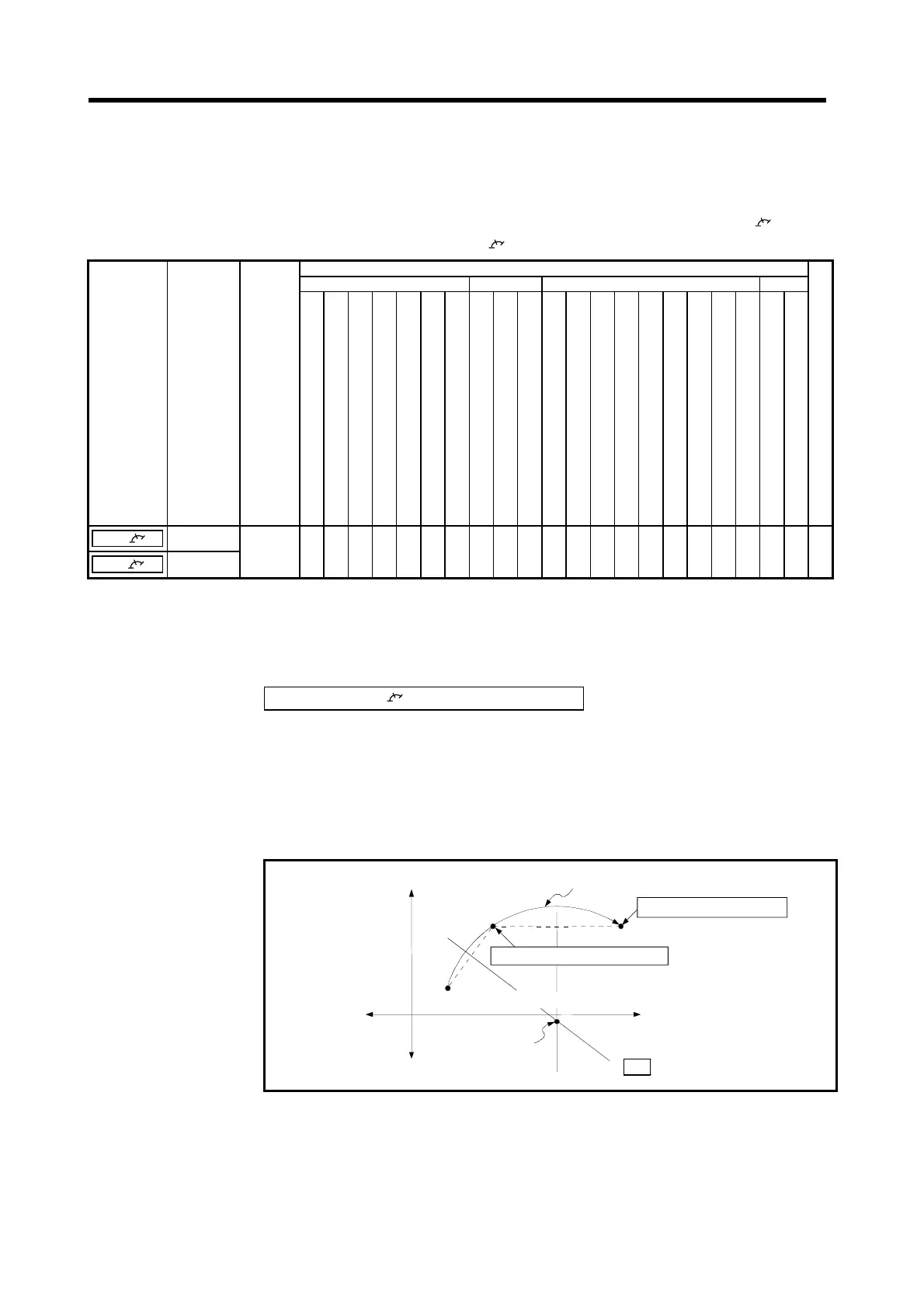

Items Set by Peripherals

Common Arc Parameter Block Others

Servo

Instruction

Positioning

Method

Number of

Controllable

Axes

Parameter Block No.

Axis

Address/Travel Value

Commanded Speed

Dwell Time

M-Code

Torque Limit Value

Auxiliary Point

Radius

Center Point

Control Unit

Speed Limit Value

Acceleration Time

Deceleration Time

Rapid Stop Deceleration Time

Torque Limit Value

Deceleration Processing on Stop Input

Allowable Error Range for Circular Interpolation

S-Curve Ratio

Cancel

Start

Speed Change

ABS

Absolute data

INC

Incremental

2 ∆ !!! ∆∆ ! ∆∆∆∆∆∆∆∆∆∆∆OK

! : Must be set

∆ : Set if required

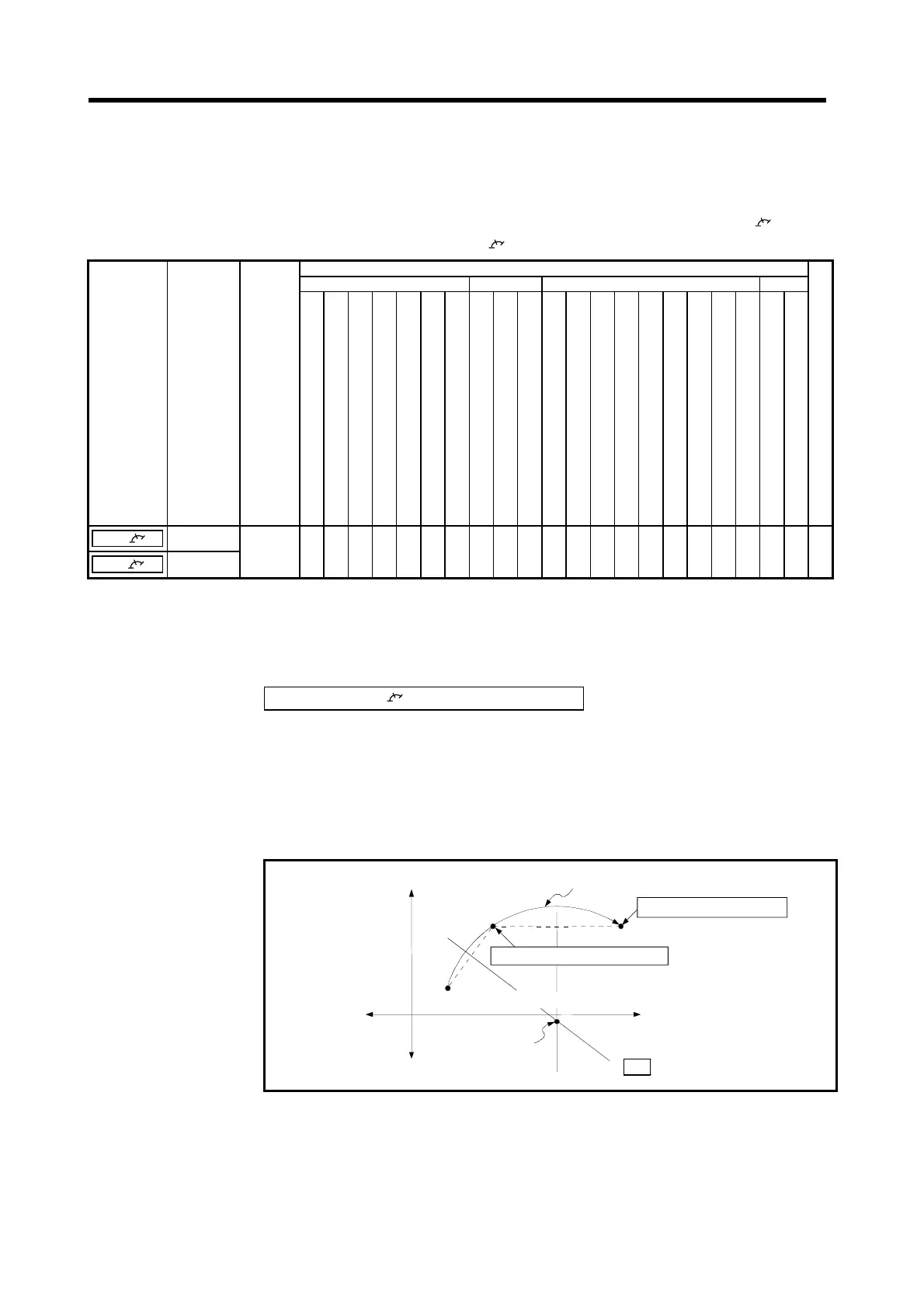

[Control Details]

Control with ABS

(absolute data method).

(1) Circular interpolation from the current stop address (pre-positioning address)

through the designated auxiliary point address to the end point address, using

the home position as the reference.

(2) The center of the arc is the point of intersection of the perpendicular

bisectors of the start point address (current stop address) to the auxiliary point

address, and the auxiliary point address to the end point address.

: indicates set data

Forward direction

0

Reverse

direction

Reverse direction

Movement due to circular interpolation

Forward direction

Start point address (X

0

, Y

0

)

Auxiliary point address (X

2

, Y

2

)

End point address (X

1

, Y

1

)

Center of arc

Fig.7.9 Circular Interpolation Control by Absolute Data Method

Loading...

Loading...