4. PARAMETERS FOR POSITIONING CONTROL

4 − 10

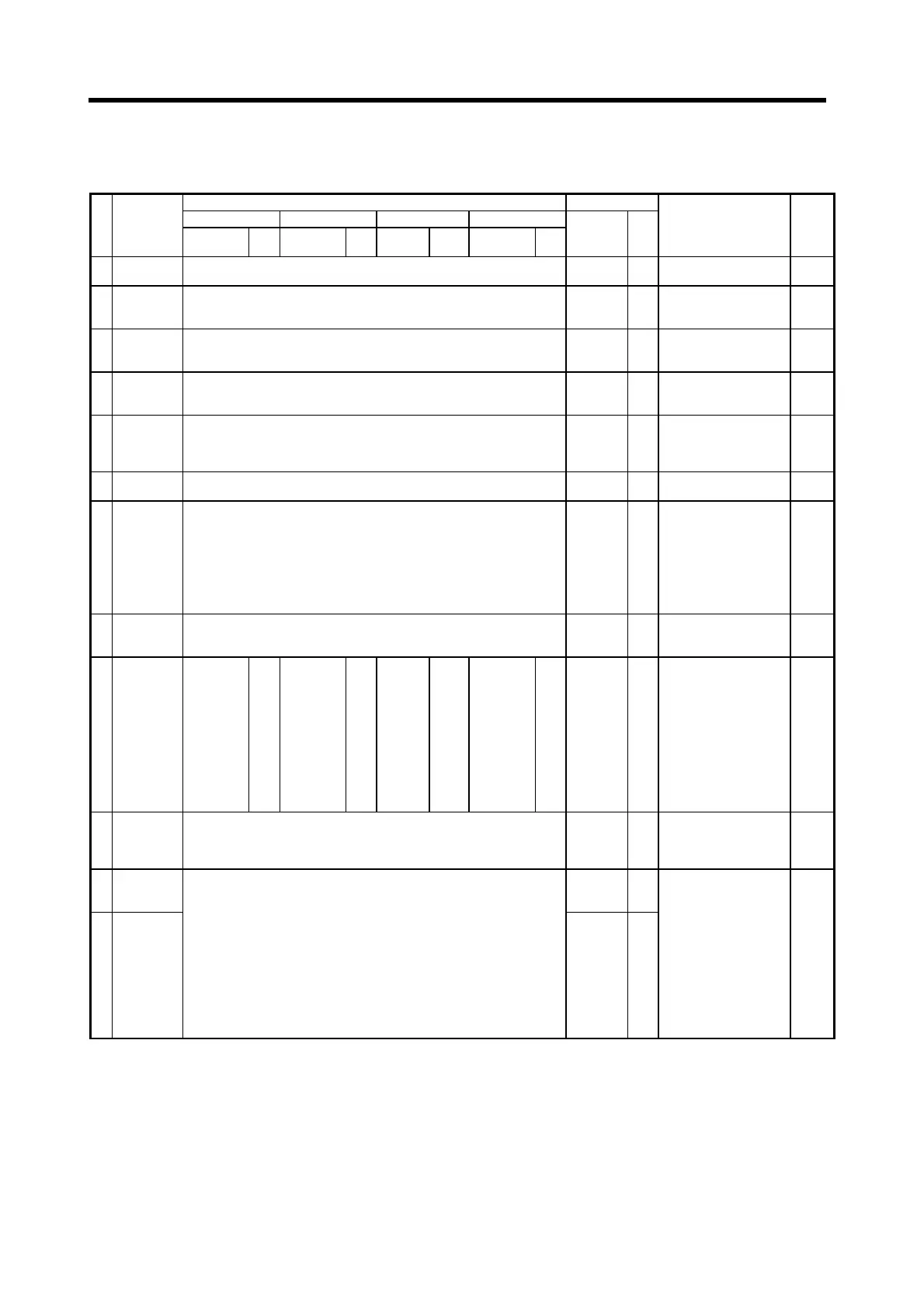

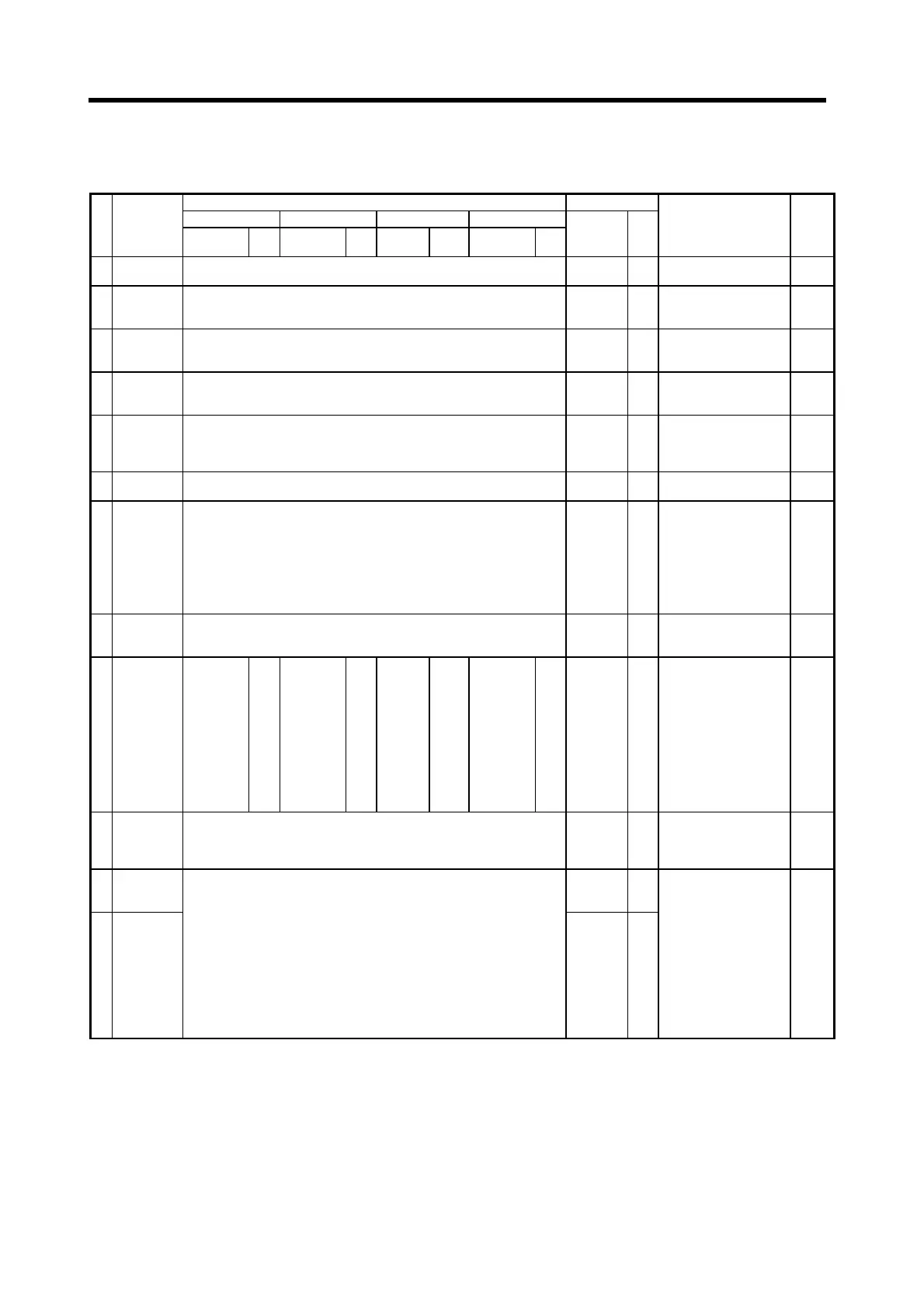

(2) Adjustment parameters

Table 4.5 Servo Parameter List (Adjustment Parameters)

Setting Range Default

mm inch degree PULSE

No. Item

Setting

Range

Units

Setting

Range

Units

Setting

Range

Units

Setting

Range

Units

Initial Value Units

Remarks

Expla-

natory

Section

1

Load inertia

ratio

0.0 to 100.0

3.0

(Note-1)

• Set the ratio of moment of

load inertia for the motor.

4.3.8

2

Position

control gain 1

Valid range 4 to 1000 rad/s Setting range 1 to 9999 rad/s 70 rad/s

• Set to increase the follow-

up with respect to the

position command.

4.3.3

3

Speed control

gain 1

Valid range 20 to 5000 rad/s Setting range 1 to 9999 rad/s 1200 rad/s

• Set to increase the follow-

up with respect to the

speed command.

4.3.4

4

Position

control gain 2

Valid range 10 to 500 rad/s Setting range 1 to 9999 rad/s 25 rad/s

• Set to increase the position

response with respect to

load disturbance.

4.3.3

5

Speed control

gain 2

Valid range 20 to 5000 rad/s Setting range 1 to 9999 rad/s 600 rad/s

• Set when vibration is

generated, for example in

machines with a large

backlash.

4.3.4

6

Speed integral

compensation

Valid range 1 to 1000 rms Setting range 1 to 9999 rad/s 20 ms

• Set the time constant for

integral compensation.

4.3.5

7 Notch filter

0: Not used

1: 1125

2: 750

3: 562

4: 450

5: 375

6: 321

7: 281

0Hz

• Set the frequency for the

notch filter.

4.3.11

8

Feed forward

gain

0 to 100%

0: Feed forward control is not executed.

0%

• Set the feed forward

coefficient used in

positioning control.

4.3.7

9

In-position

range

(Note-2)

0.1 to

214748364.7

µ

m

0.00001

to

21474.83647

inch

0.00001

to

359.99999

degree

1 to

2147483647

PLS 100 PLS

• Sets the quantity of droop

pulses in the deviation

counter.

• The in-position signal is ON

when the number of droop

pulses is within the set

range. The expression

below shows the setting

range.

1 ≤ (in-position range) ×

AP/AL ! AM ≤ 32767

4.3.6

10

Electromag-

netic brake

sequence

0 to 1000 ms 100 ms

• Set the time delay between

actuation of the

electromagnetic brake and

base disconnection.

4.3.12

11

Monitor output

mode

(monitor 1)

0

12

Monitor output

mode

(monitor 2)

(MR-H-BN)

0: Speed (±)

1: Torque (±)

2: Speed (+)

3: Torque (+)

4: Current command output

5: Command F∆T

6: Droop pulse 1/1

7: Droop pulse 1/4

8: Droop pulse 1/16

9: Droop pulse 1/32

(MR-J2S-B/MR-J2-B)

0: Speed (±)

1: Torque (±)

2: Speed (+)

3: Torque (+)

4: Current command output

5: Command F∆T

6: Droop pulse 1/1

7: Droop pulse 1/16

8: Droop pulse 1/64

9: Droop pulse 1/256

10: Droop pulse 1/1024

1

• Set the monitor items

output as analog outputs in

real time.

4.3.13

(Note-1) : For MR-J2S-B/MR-J2-B, the default is "7.0".

(Note-2) : The display of the possible setting range differs according to the electronic gear value.

Loading...

Loading...